Electrostatic discharges, often abbreviated as ESD, occur almost constantly in our everyday lives. However, we humans do not usually feel them, as they can only be perceived by us at a certain strength, approximately 2,000 volts.

The most common everyday situation in which we experience electrostatic discharge is probably when we touch a metal banister. Since the human body is very poor at dissipating electrical charges, static charges build up during everyday activities and are then quickly – and painfully – discharged when we touch a conductive object.

However, electrostatic discharges are dangerous for components even at much lower voltages. Electrostatic discharge can cause damage to sensitive components at voltages as low as 10 volts, and at higher voltages, these components can even ignite.

Many industries therefore rely on materials that completely prevent electrostatic discharge. Although traditional manufacturing methods offer a selection of ESD-safe materials, the production of such components using these methods is associated with a number of difficulties.

In recent years, the range of ESD-safe materials designed for 3D printing has multiplied, which is why more and more companies are turning to additive manufacturing for their components. This blog post aims to explain the reasons for this change and show how we, as a 3D printing service provider, ensure that our customers receive maximum safety.

What is electrostatic discharge?

I have already provided a brief and well-known insight into the consequences of electrostatic discharge using the example of metal stair railings, but a little more detail is needed to fully understand the concept of electrostatic discharge.

Electrostatic discharge is, of course, preceded by charging. This can occur in various ways, but in the case of electrostatic discharge, the cause is usually friction electricity or the triboelectric effect.

When two different components come into contact, electrons are transferred from one material to the other if the two components have different electron affinities, also known as triboelectric series. This is usually the case with components made of different materials, but can also happen with components made of the same materials. The component that receives the excess electrons becomes negatively charged, while the other component becomes positively charged.

Repeated friction or contact increases this electron imbalance and thus also the static charge. Although air can slowly dissipate this charge, this is not sufficient, especially in very dry air, which means that the voltage difference cannot be equalised.

If this voltage difference in the air exceeds 3 MV/m, the air becomes electrically conductive, causing the electrons to jump through the air in an uncontrolled manner. This process is also known as dielectric breakdown and is the process responsible for electrostatic discharge.

Which materials are susceptible to electrostatic discharge?

Now that we have taken a look at the process of electrostatic discharge, let's take a look at which materials are particularly susceptible to this phenomenon.

Basically, materials can be divided into three different types – conductive materials, insulating materials and dissipative materials, whereby dissipative materials are precisely those materials that ensure ESD safety.

Conductive materials have very low surface resistance, usually less than 10³ ohms, which allows electrons to move freely across the component and thus prevents static charging. Examples of such materials include many metals.

If only such materials are used, there is no risk of electrostatic discharge. However, as our previous example with the banister shows, the combination of conductive and insulating materials can still lead to electrostatic discharge if the electron affinity of the insulating material is higher than that of the conductive material. In addition, conductive materials increase the risk of other electrical hazards, such as short circuits.

Insulating materials are the exact opposite of conductive materials. They have a very high surface resistance, usually above 10¹² ohms, which prevents electrons from moving freely across the component and thus leading to a build-up of charge.

This category includes most plastics, as well as glass and ceramics. This category poses the greatest risk of electrostatic discharge. Even with only the smallest differences in electron affinity between individual components, enough voltage can build up on the components during continuous operation and dry air, which is then discharged in a destructive shock.

With a surface resistance between 10⁶ and 10⁹ ohms, dissipative materials are the ‘golden mean’. This ensures that electrons can move across the component, but in a much more controlled manner than with conductive materials, which provides ideal protection against electrostatic discharge.

However, materials with this degree of surface resistance do not occur naturally, which is why they have to be specially formulated. This usually involves combining plastics with conductive fillers, such as carbon fibres, to achieve a symbiosis between the high surface resistance of the plastic and the low surface resistance of the filler.

These material properties are now found in a wide range of 3D printing materials. Whether resin, filament or powder, ESD-safe materials are now available across all plastic printing technologies.

Advantages of 3D printing for ESD-safe components

Additive manufacturing for ESD-safe components offers numerous advantages, which we will now discuss in detail, focusing on the most important ones.

Design freedom

One of the biggest advantages of 3D printing is the unlimited design freedom it offers. Whether complex geometries, fine details or internal structures, additive manufacturing offers countless possibilities for the electronics industry to implement ideas and designs.

This design freedom comes into its own in a wide range of applications. Whether it's electronic housings with integrated ventilation channels, connectors with custom shapes or complex assemblies that can be produced as a single component thanks to 3D printing, the doors opened by additive manufacturing are unique.

Reduced lead times

Compared to other industries, the electronics industry is a relatively volatile market. Due to the constant increase in product complexity and frequent fluctuations in the supply-demand ratio, order books can quickly go from empty to overflowing, posing major challenges for manufacturers with conventional manufacturing processes.

However, thanks to the use of additive manufacturing, these challenges are no longer an issue. There are no changeover times to consider, no tools to provide and no large-scale production changes to plan. Once the digital model is available, all that is needed is the right material in the printer and production can start at the touch of a button, making it easy to cope with short-term changes in design or production volume.

Cost efficiency

As in any other industry, production costs are also of paramount importance to the electronics industry. Due to the special material properties required for the production of electronic components, scrap plays a particularly important role, as the materials are in the higher price segment.

While conventional production methods can achieve scrap rates of up to 90%, additive manufacturing only uses the material that is absolutely necessary. The scrap rate for 3D printing is only between 3 and 5% on average, which already includes the necessary support structures. This can result in massive cost savings, especially in series production, but individual production also benefits from lower production costs due to reduced labour requirements.

Rapid Prototyping

Inherently linked to shorter lead times, but still worthy of its own section due to the importance of a comprehensive prototyping process within the electronics industry, 3D printing is the perfect way to transform the classic prototyping process into rapid prototyping.

Additive manufacturing can shorten iteration cycles many times over. This allows all aspects of a product, whether design, functionality or safety, to be tested more extensively, ultimately leading to more sophisticated end products.

Our options for ESD-safe components

As one of Europe's largest 3D printing service providers, we are particularly committed to the electronics industry, with the aim of making the advantages of this technology fully available to companies without them having to incur high acquisition costs.

In addition to our large capacity of 3D printing equipment, which enables us to cover a wide range of requirements and production volumes – from single pieces to large series – we focus primarily on materials that guarantee the best possible ESD safety.

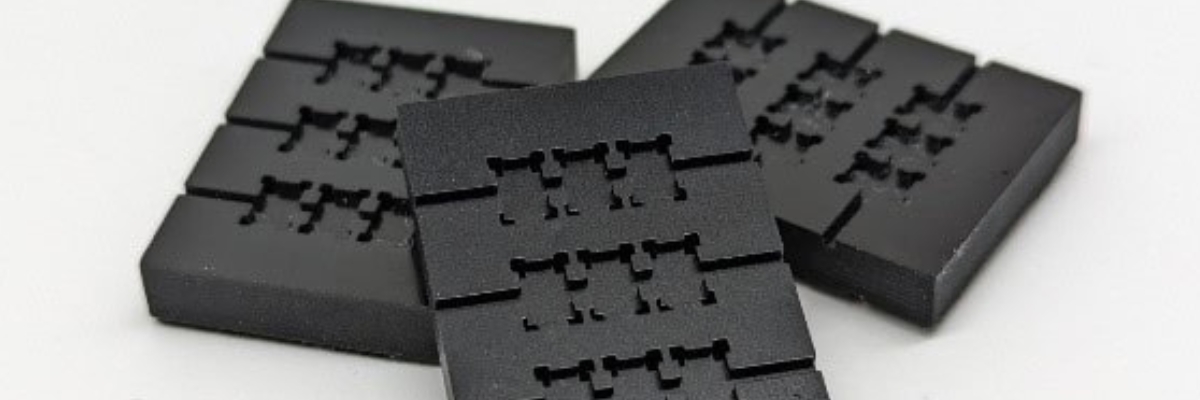

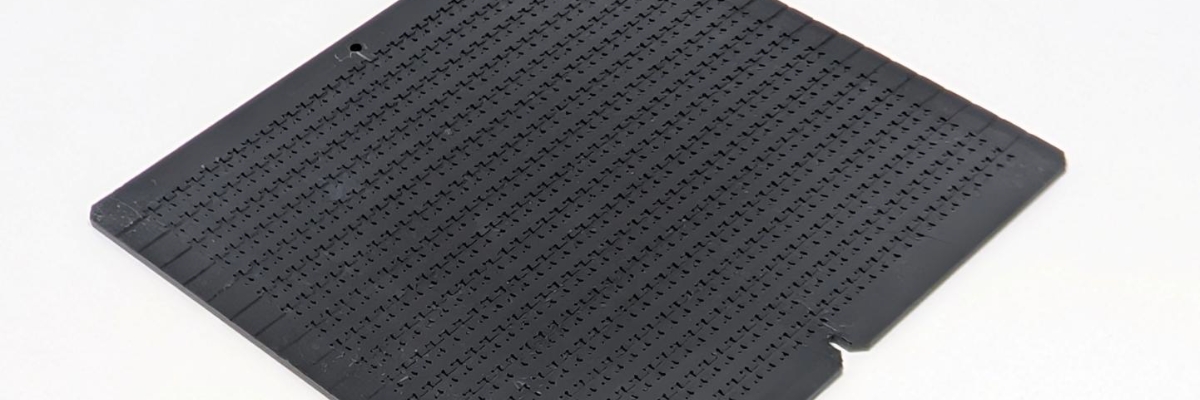

For this reason, last month we entered into an exclusive partnership with materials manufacturer Mechnano, which is known for its exceptional D'Func technology. This technology greatly improves the dispersion of functionalised carbon tubes, which not only improves performance and durability, but also ensures uniform mechanical properties across the entire component.

This partnership enables us to offer our customers and partners exclusive access to Mechnano's exceptional Formula1B resin for their projects. This material impresses with an isotropic surface resistance of 10⁷ ohms, excellent chemical resistance and outstanding surface quality and detail.

If you would like to find out more about the possibilities of 3D printing, our service portfolio or Mechnano's materials for the electronics industry, you can meet our experts at Rapid.Tech 3D at stand 2-109. We will be happy to advise you on the best approach for switching to additive manufacturing!