Post-processing of dental indications made easy

Resin 3D printing has now become fully established in the dental industry. From small dental practices to large dental laboratories, from MSLA to PolyJet™ printers and from models to dental prostheses – additive manufacturing technology has become an integral part of dentistry.

The various printing technologies and systems all boast a high degree of automation and outstanding properties such as durability, biocompatibility and many more. However, this level of automation has not yet been achieved for the post-processing of dental parts. Although solutions exist for automating individual post-processing steps, most practices and laboratories do not have the space required for multiple post-processing systems.

In today's blog post, however, I would like to present the latest post-processing solution from PostProcess Technologies®, which fully automates the entire post-processing of dental parts in a compact format.

First, I will discuss the various steps that are essential for post-processing 3D-printed dental parts and which can all be performed by this new post-processing solution.

Cleaning and rinsing

When the dental parts are removed from the respective printing system, there will inevitably be excess resin on them. This excess, uncured resin must of course be removed from the component as quickly as possible after the end of the printing process to prevent accidental curing.

However, due to the viscous consistency of the resin, it cannot simply be washed off. First, a solvent must be used, typically IPA, which forms solvathen around the individual epoxy molecules or chains. This liquefies the resin, allowing it to be rinsed off.

The classic method for this step is cleaning with a stiff-bristle brush, but this is very time-consuming and labour-intensive. Washing stations are now available for automation, but these have another problem besides the space they require: the use of IPA.

Although IPA is an excellent solvent, it is also highly toxic, which limits its use in dental applications, especially those that come into contact with the gums.

Drying

A frequently underestimated step is drying. Before the final post-processing step, post-curing, can begin, the dental parts must be completely dry, as otherwise surface irregularities may occur during post-curing, rendering the entire batch unusable.

Air drying is the conventional method. However, this option involves long waiting times. Some curing stations come with an integrated drying function, but these are designed for industrial use and are therefore not space-saving.

Post-curing

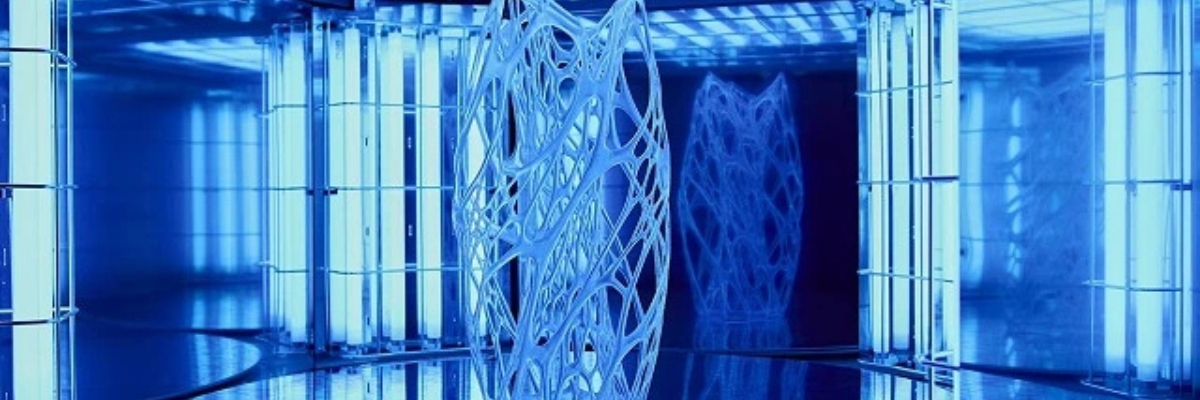

Post-curing is the final essential step in the finishing process for all types of dental restorations. During this process, the dental restorations are cured again in a chamber that uses UV light and/or heat to maximise their mechanical properties and longevity.

To achieve uniform results, a special curing station is always required. Although these are also available in desktop format, they only offer space for individual dental components, which would mean that several of these desktop units would be required, particularly in dental laboratories.

The perfect solution for the dental industry – the DEMI X 200 Plus

The US manufacturer PostProcess Technologies®, one of the pioneers in post-processing solutions for industry, has now turned its attention to dentistry and launched the DEMI X 200 Plus for this sector.

This post-processing solution integrates all the aforementioned post-processing steps into a single system with a compact footprint of only 550 x 505 x 600 mm.

This system not only provides easy integration of all steps, but also combines this integration with maximum automation and delivers a completely IPA-free workflow thanks to the company's proprietary PostProcess solvents.

These solvents not only offer safer handling, but also feature a formulation specially designed for resin removal. When these solvents are used, surfactants form and wrap around the resin particles. This emulsifies the resin, making it much easier and more efficient to rinse off, which significantly reduces the processing times of the DEMI X 200 Plus.

Processing times are a key factor, and this is another area where the DEMI X 200 Plus scores highly. Dental practices and dental laboratories can completely post-process their dental parts after printing with this post-processing solution in less than 30 minutes – and apart from inserting and removing the dental parts and pressing a button to start the process, no further work is required.

However, these 30 minutes are not only enough to post-process individual dental parts. Despite its compact footprint, the DEMI X 200 Plus offers a basket size of 160 x 100 x 200 mm, allowing up to ten dental parts, such as dental arches or drilling templates, to be post-processed simultaneously.

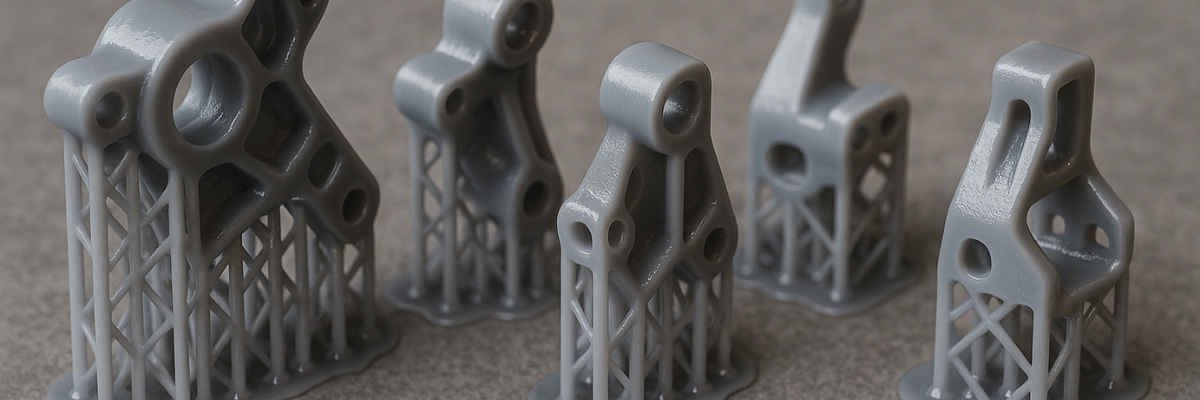

While time and space savings are important, the results are just as important – and this is where the DEMI X 200 Plus really shines. Thanks to the use of patented SVC (Submersed Vortex Cavitation) technology, even dental parts with complex shapes and small details are cleaned effectively. The drying and curing process can also be fine-tuned with the DEMI X 200 Plus using a wide range of settings, ensuring outstanding results even when using different materials and in a wide variety of applications.

The entire DEMI X 200 Plus package is rounded off with advanced safety features, a user-friendly interface and a unique symbiosis of hardware, software and chemistry, making it the ultimate all-rounder for post-processing in dental practices and dental laboratories.

Further information on the DEMI X 200 Plus can be found here. If you are interested in taking your dental production to a new level, simply contact our experts – we will be happy to advise you!