Neo®-Series

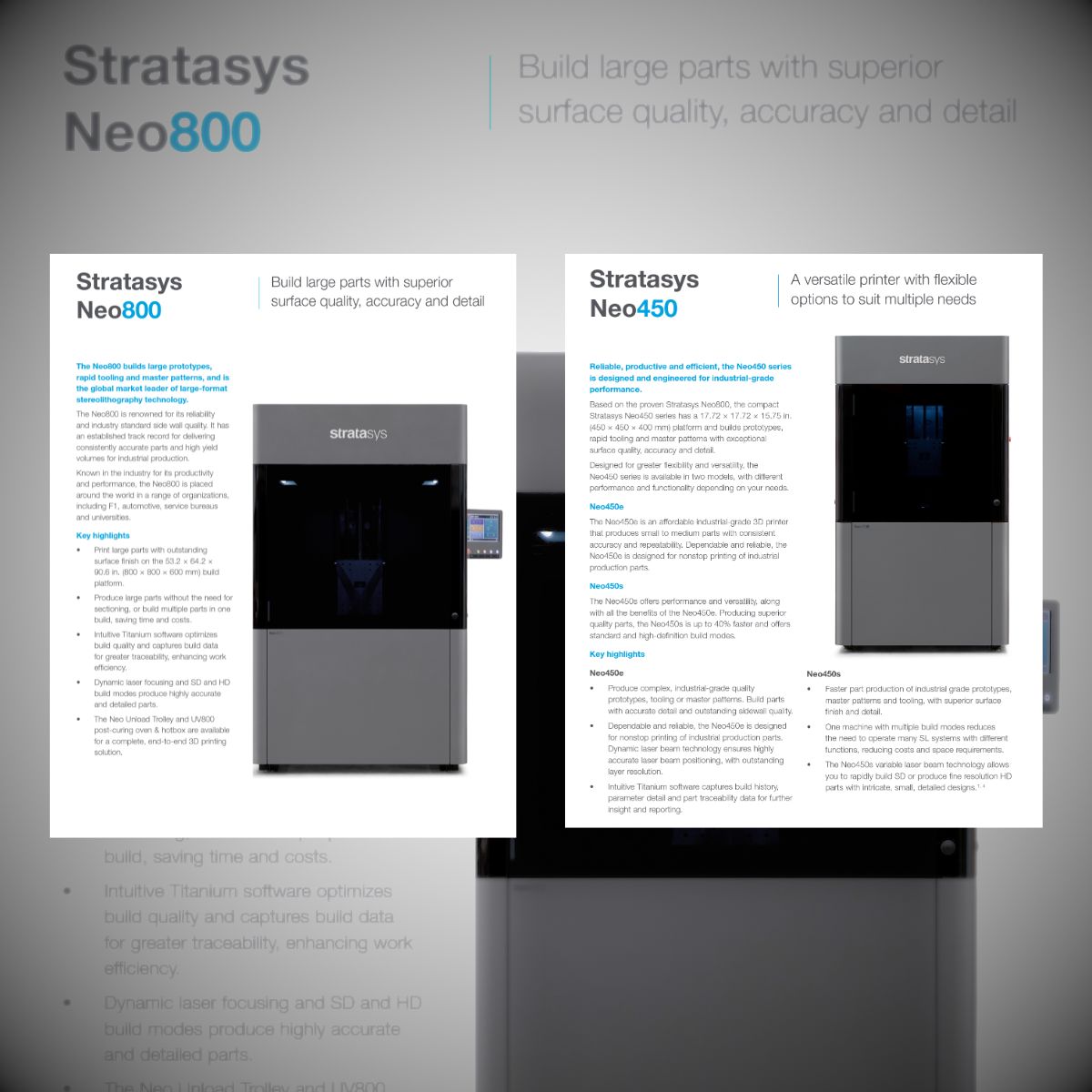

For medical device manufacturers and healthcare institutions seeking high-precision prototyping and production solutions, the Stratasys® Neo®-Series is perfect for creating large-format parts.

-

SLA (Stereolithography) Printing Technology

-

450 x 450 x 400 mm / 800 x 800 x 600 mm Build Volume

-

50 to 200 μm Layer Thickness

-

Unlimited (Open Platform) Material Compatibility

-

2 (HD/SD) Build Modes

Detailed Small And Large Parts

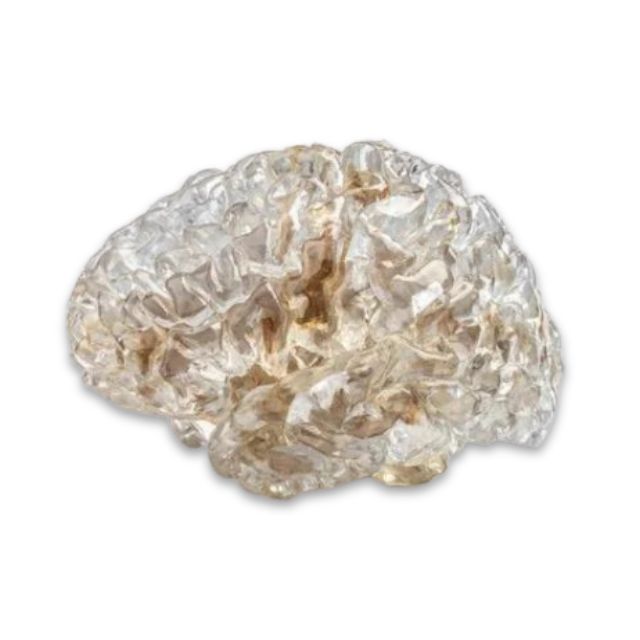

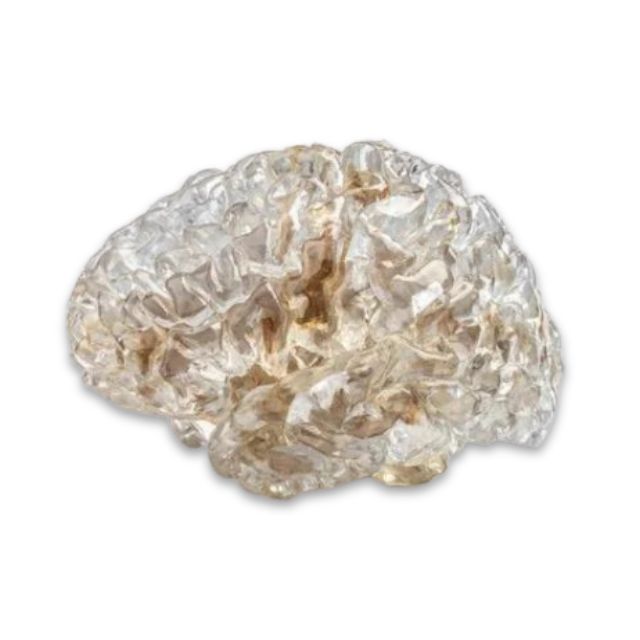

The remarkable precision and versatility of the Stratasys® Neo®800 and Neo®450s for medical applications are essential for producing sophisticated medical device prototypes, patient-specific surgical guides, and intricate anatomical models.

These printers create incredibly precise and accurate parts with features as small as 0.1524 mm thanks to dynamic laser focusing and selectable SD and HD build modes. For makers of medical devices creating complex parts like cardiovascular stents or even dental implants, this degree of accuracy is especially helpful.

The large build volumes (450 x 450 x 400 mm for Neo®450s and 800 x 800 x 600 mm for Neo®800) enable the production of multiple smaller medical parts or full-scale anatomical models in a single build, improving medical manufacturing efficiency and cutting down on production time for surgical planning models.

Open Material System

Medical professionals and device manufacturers can utilize any commercially available 355 nm stereolithography resin, including biocompatible materials like Somos® BioClear and Somos® DXM SL 100, thanks to the Stratasys® Neo®-Series 3D printers' open resin system.

Medical device manufacturers and research organizations especially benefit from this adaptability since it enables them to experiment with different resin compositions and choose materials that satisfy certain biocompatibility standards for a range of uses, from functional implantable device prototypes to surgical planning models.

For more accurate surgical training and device testing, a variety of materials can be used to create models with varying mechanical qualities that simulate different tissue types.

Intelligent Software

The user-friendly Titanium software that comes with the Neo®800 and Neo®450s printers maximizes build quality and records construction information for improved traceability.

Viscosity monitoring for material longevity, remote construction monitoring via an onboard camera, email notifications of build status, laser monitoring with simple recalibration, job diagnostic packets for effective troubleshooting, and system alarms are all included. In the manufacturing of medical devices, where quality control and documentation are essential for regulatory compliance, this capability is essential.

The program facilitates adherence to FDA laws and ISO standards in the medical sector by offering build history, parameter data, and part traceability reports. For medical device producers to navigate the complicated regulatory environment and guarantee the efficacy and safety of their goods, this degree of documentation is crucial.

Development Streamliner

The Neo®-series provides notable benefits for short-term manufacturing and quick prototyping of medical instruments and equipment. Complex medical tools and devices can be created with little post-processing thanks to the printers' huge build volumes and remarkable surface quality and detail capabilities.

Rapid design iterations and prototype production are made possible by the Neo®-series printers' ability to build at up to 2 liters per hour. To illustrate the Neo®450s' capacity for short-run manufacturing of end-use parts that adhere to strict quality control standards, Hirsh Prototypes utilized it to create 20,000 snap assemblies for a medical device project in a matter of weeks. This combination of speed, precision, and scalability makes the Neo®-series an invaluable tool for medical device manufacturers looking to streamline their development process and respond quickly to market demands or urgent medical needs.

Add-on Workflow Solutions

An essential component of Stratasys®' complete end-to-end 3D printing solution for stereolithography (SLA) operations is the Neo® Unload Trolley alongside the UV800 post-curing oven & hotbox.

The Neo® Unload Trolley improves workflow efficiency and safety by making it easy to remove and move completed build platforms and printed components up to 40 kg from the Neo®800 printer to the cleaning area. By using a controlled UV exposure technique, the UV800 post-curing oven with a hotbox feature is intended to maximize the final strength and performance of printed parts. In order to achieve the appropriate material qualities and guarantee that parts are safe to handle without protective gear, this post-curing procedure is essential.

In professional 3D printing settings, these add-ons improve productivity and part quality by streamlining the post-processing workflow.

Applications

Rapid Prototyping

Produce incredibly detailed and precise prototypes with excellent surface quality to facilitate quicker design validation and iterations for medical equipment and devices.

Tools and Molds

Produce short-run end-use components, tools, and molds with remarkable dimensional accuracy and sharp feature resolution, perfect for the production of medical devices and customized surgical instruments.

Medical Model Creation

Create highly accurate surgical guides and patient-specific anatomical models to aid in surgery planning, medical education, and device testing.

Functional Testing

Utilize the printers' capacity to use biocompatible materials, such as Somos® BioClear, to create components for functional prototypes and testing, allowing for the assessment of medical devices that come into contact with the body

Compatible Materials

Stratasys® Somos® DMX-SL 100

Stratasys® Somos® WaterShed® Black

Stratasys® Somos® NeXt™

Stratasys® Somos® ProtoTherm™ 12120

Stratasys® Somos® WaterClear Ultra 10122

Stratasys® Somos® WaterShed® AF

Stratasys® Somos® Element™

Stratasys® Somos® EvoLVe 128

Stratasys® Somos® GP Plus™ 14122

Stratasys® Somos® Momentum™

Stratasys® Somos® PerFORM HW

Stratasys® Somos® PerFORM Reflect

Stratasys® Somos® Watershed® XC 11122

Stratasys® Somos® 9120

Stratasys® Somos® Taurus™