What does FR stand for?

The ability of a material to withstand or retard the spread of flames when exposed to a heat source or an open flame is known as flame retardancy (FR). Reduced flammability of substances limits the spread of fire and buys more time for evacuation or other action to minimise possible damage. This is the aim of flame retardant compounds.

What are the characteristics of flame retardant materials?

Ignition Resistance

When exposed to heat or flames, flame-retardant materials are made to resist igniting. When compared to materials that are not flame retardant, they have a higher ignition threshold.

Reduced Flame Spread

The goal of flame retardant materials is to slow the spread of flames in the event of an ignition. This is essential to limiting the possibility of significant damage and preventing a quick escalation of the fire.

Limited Heat Release

When burning, flame-retardant materials frequently emit less heat. This feature adds to the environment's overall safety by preventing the fire from getting worse.

Formation of a Protective Char Layer

When exposed to fire, certain flame-retardant materials produce a protective char layer. By acting as a barrier, this layer keeps the substance behind it from burning much longer and acts as insulation.

Self-Extinguishing Properties

When the ignition source is removed, the material will extinguish itself. This characteristic is necessary to stop materials from burning continuously.

What are the flame retardancy standards?

UL 94 Rating

Plastic materials' flammability is categorised according to the UL 94 standard. After the flame is extinguished, components with a V-0 rating self-extinguish in 10 seconds. Longer after-burn periods are indicative of weaker flame resistance for V-1 and V-2 classifications.

ASTM E84

The ASTM E84 Flame Spread Index gauges how well construction materials burn on the surface. Better resistance to flames is indicated by a lower Flame Spread Index. Materials in Class A have a Flame Spread Index of no more than 25.

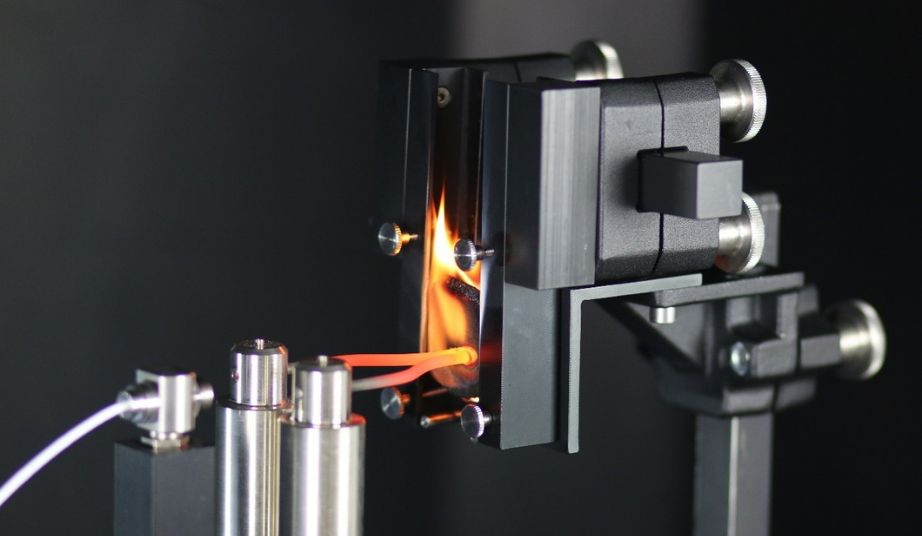

Glow Wire Test

The Glow Wire Test is frequently used in the electrical industry in particular. In this test, a plastic is brought into contact with a wire heated up to 960 °C by an electric current. This test is considered to have been passed if the plastic does not start to burn or any flame that occurs is self-extinguished after 30 seconds at the latest.

What are the costs connected with fire damages?

Economic Impact

The economic impact of fire damage can be horrendous for both individual companies and entire economies. For example, according to the Insurance Information Institute, fires in the United States caused direct property damage amounting to USD 52.9 billion in 2019.

Business Continuity Losses

Serious losses in terms of company continuity can result from fires. According to estimates from the National Institute for Occupational Safety and Health (NIOSH), 25% of businesses close their doors following a significant fire.

What are the benefits of 3D printing FR applications?

On-demand Printing

On-demand printing increases production flexibility by eliminating the need for massive, pre-printed replacement parts, stocks and decreasing waste. This streamlined method not only saves money, but it also improves sustainability by manufacturing only what is needed at the right time. Furthermore, the immediacy of on-demand printing allows for a quick response to changing safety requirements and growing needs, making it a flexible and future-proof solution for flame retardant applications.

Integration of Multiple Materials

Some 3D printing systems enable the use of various materials in a single print process. This capacity can be used to design flame retardant components with integrated features or layers, which improves overall performance and safety.

Complex Internal Structures

It is frequently difficult to build components with complex internal structures that improve flame retardancy using traditional manufacturing procedures. Complex interior geometries, including lattice structures, that maximise flame resistance by dispersing heat and reducing fuel sources are a specialty of 3D printing.

What are the applications of 3D printing in FR-sensitive industries?

Parts for Aerospace

3D printing makes it possible to produce flame-retardant parts for aeroplane interiors, which is important in the aerospace sector where weight and fire safety are major concerns. 3D printing provides an adaptable way to satisfy demanding safety regulations for everything from structural components to cabin parts.

Interior Parts for Automobiles

3D printing helps the car industry by providing flame-retardant solutions for the production of interior components. It is possible to modify and build dashboard pieces, seat frameworks, and other essential components with increased flame resistance.

Housings for Electronics

Customized enclosures can be manufactured precisely and effectively with 3D printing, especially considering the growing demand for flame-retardant electronics. By protecting electronic components from fire risks, these enclosures ensure the reliability and safety of electronic devices.

What materials do we recommend for 3D printing FR-compliant components?

ULTEM™ AM9085 from Stratasys® - Printed on the Stratasys® Fortus® 450mc

With FDM® technology, ULTEM™ 9085 filament is a high-performance thermoplastic with exceptional mechanical and physical qualities for specialised and high-demand applications. Being one of the strongest Stratasys® FDM® materials, it is ideal for high-strength/low-weight applications due to its high strength-to-weight ratio.

ULTEM™ 9085 filament also fulfils numerous transportation industry standards for flame, smoke, and toxicity requirements, and it has excellent chemical tolerance and strong impact resistance.

Stratasys® ULTEM™ AM9085 resin is UL 94-V0 rated.

The Stratasys® Fortus® 450mc is engineered for optimal productivity in manufacturing. Through reducing design and build times, optimising production procedures, reducing overall costs, and fostering creativity in the workplace, the FDM® 3D printer provides a multi-application manufacturing solution that accelerates time to market. A multi-tool for additive manufacturing, the Fortus® 450mc can precisely print the ULTEM™ 9085 filament.

Fortus® 450mc

Have your components 3D printed now! Do you have any questions? Contact our experts!

INFINAM® PA 6004 P from Evonik - Printed on the Nexa3D® QLS 236/260

INFINAM® PA 6004 P, a fine powder made from polyamide 12, manufactured by industrial giant Evonik, enables the additive manufacturing of flame-retardant components using all common powder-based 3D printing technologies.

The V0@2mm classification of INFINAM® PA 6004 P ensures that flames are extinguished within a maximum of 10 seconds and a maximum afterglow time of 30 seconds. In addition, Evonik INFINAM® PA 6004 P scores with a fantastic surface and detail resolution.

With an unparalleled 21-hour cycle speed, the QLS 236/260 from the American manufacturer Nexa3D® creates production parts and prototypes with strong mechanical and thermal qualities using a single 60 Watt CO2 laser. With the reliability and efficiency of the QLS 236/260, it is one of the best choices for printing the INFINAM® PA 6004 P powder.

QLS 236

QLS 260

Have your components 3D printed now! Do you have any questions? Contact our experts!

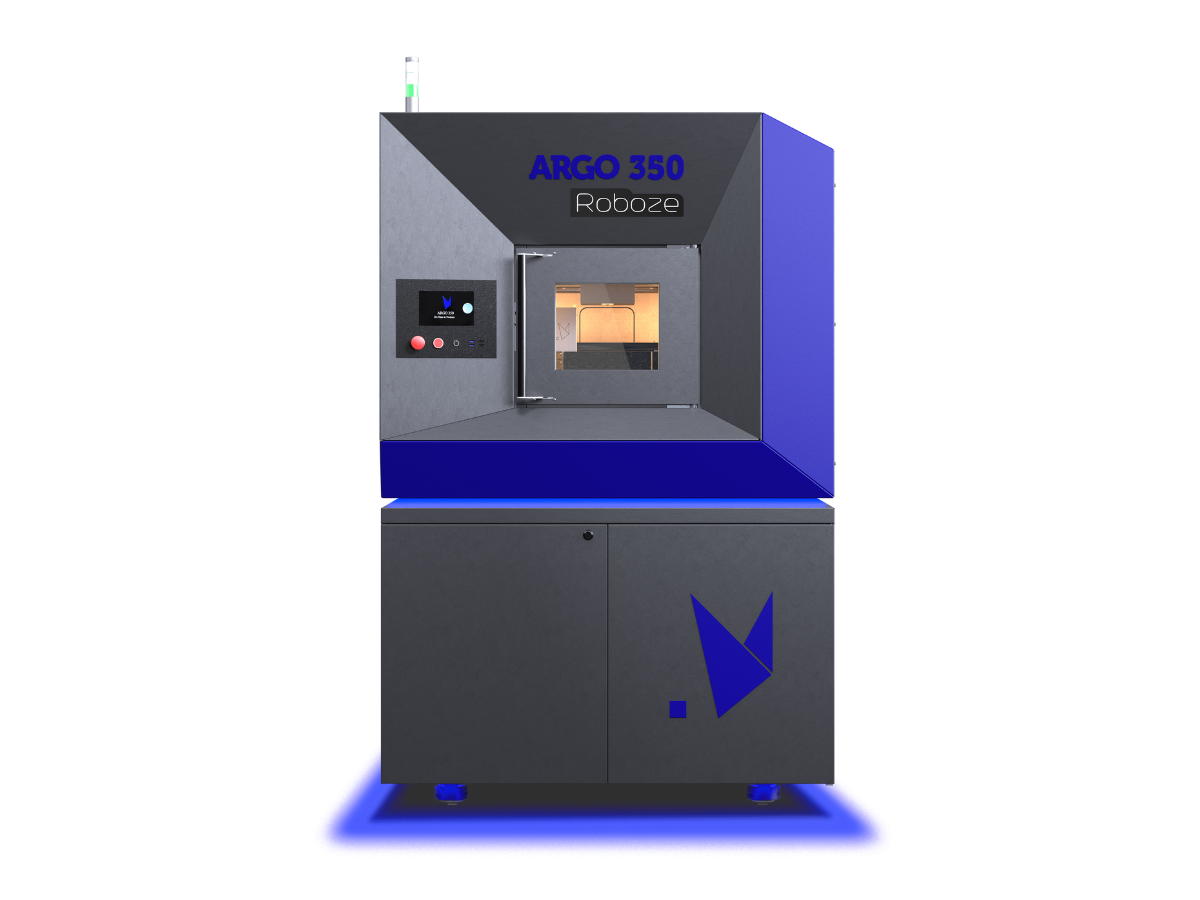

Ultrafuse® PC/ABS FR from BASF Forward - Printed on the Roboze ARGO 350

Two of the most popular thermoplastics for technical and electrical applications, polycarbonate and ABS, are combined to create Ultrafuse® PC/ABS FR Black, a V-0 flame retardant blend. When these two materials are combined, a premium material is created that combines the superior mechanical qualities of PC with the comparatively low printing temperature of ABS.

Parts printed with Ultrafuse® PC/ABS FR Black have excellent tensile and impact strength, stronger heat resistance than ABS, and can meet UL94 V-0 standard criteria when combined with a halogen-free flame retardant.

The ARGO 350 from the Italian manufacturer Roboze lets you print the Ultrafuse® PC/ABS FR with outstanding qualities. The industrial ARGO 350 printer lets you produce your parts in a matter of hours. Create large-format finished parts with a 3D printer with 10 µm positioning accuracy and consistent repeatability.

ARGO 350

Have your components 3D printed now! Do you have any questions? Contact our experts!

INFINAM® FR 4100 L from Evonik - Printed on the Nexa3D® XiP Pro

Evonik's INFINAM® FR 4100 L is classified V0@3mm according to the globally recognized UL 94 standard. This guarantees the extinguishing of a flame within 10 seconds and a maximum afterglow time of 30 seconds.

INFINAM® FR 4100 L, which was especially developed for the DLP process, also boasts fantastic elongation at break. This means that even applications in which strong, permanent forces are applied, there are no problems.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that can utilise the INFINAM® FR 4100 L resin best. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of flame retardant parts with high resolution in a matter of hours.

XiP Pro