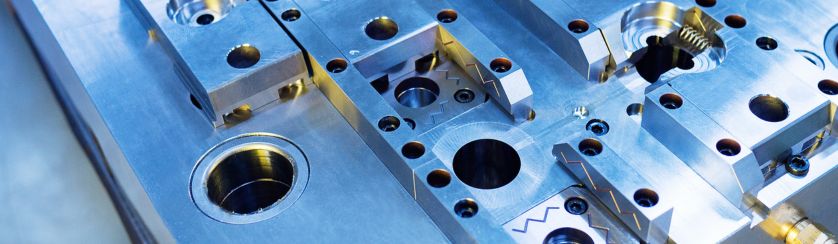

What are tooling and moulds?

The term "tooling" refers to specialised tools, dies, or fixtures used in manufacturing to shape, cut, or manipulate materials in order to produce components precisely and consistently. Moulds, jigs, and cutting instruments are examples of equipment that help manufacturers achieve the intended shape and functionality of their goods. "Moulds" are structures or cavities used in procedures such as injection moulding to shape materials, which are frequently pliable, into precise shapes. Tooling and moulds are essential components in a variety of industries, allowing for efficient and scalable manufacturing processes in automotive, aerospace, medical, and consumer goods. Their importance in ensuring precision and repeatability is critical in modern manufacturing.

What are the important characteristics of tooling and moulds in manufacturing?

Precision and Durability

Tooling and moulds must be highly precise and durable in order to provide consistent and accurate manufacturing processes, satisfy quality requirements, and minimise wear over time.

Adaptability and Maintenance

The flexibility to modify equipment for varied designs while also facilitating easy maintenance is critical. Tooling should be adaptive to design changes and capable of quick repairs to reduce downtime.

Material Compatibility and Efficiency

Compatibility between the tools, molds and the materials to be processed is essential to ensure that the production process runs smoothly. In addition, they should have innovative design features to optimize the production processes.

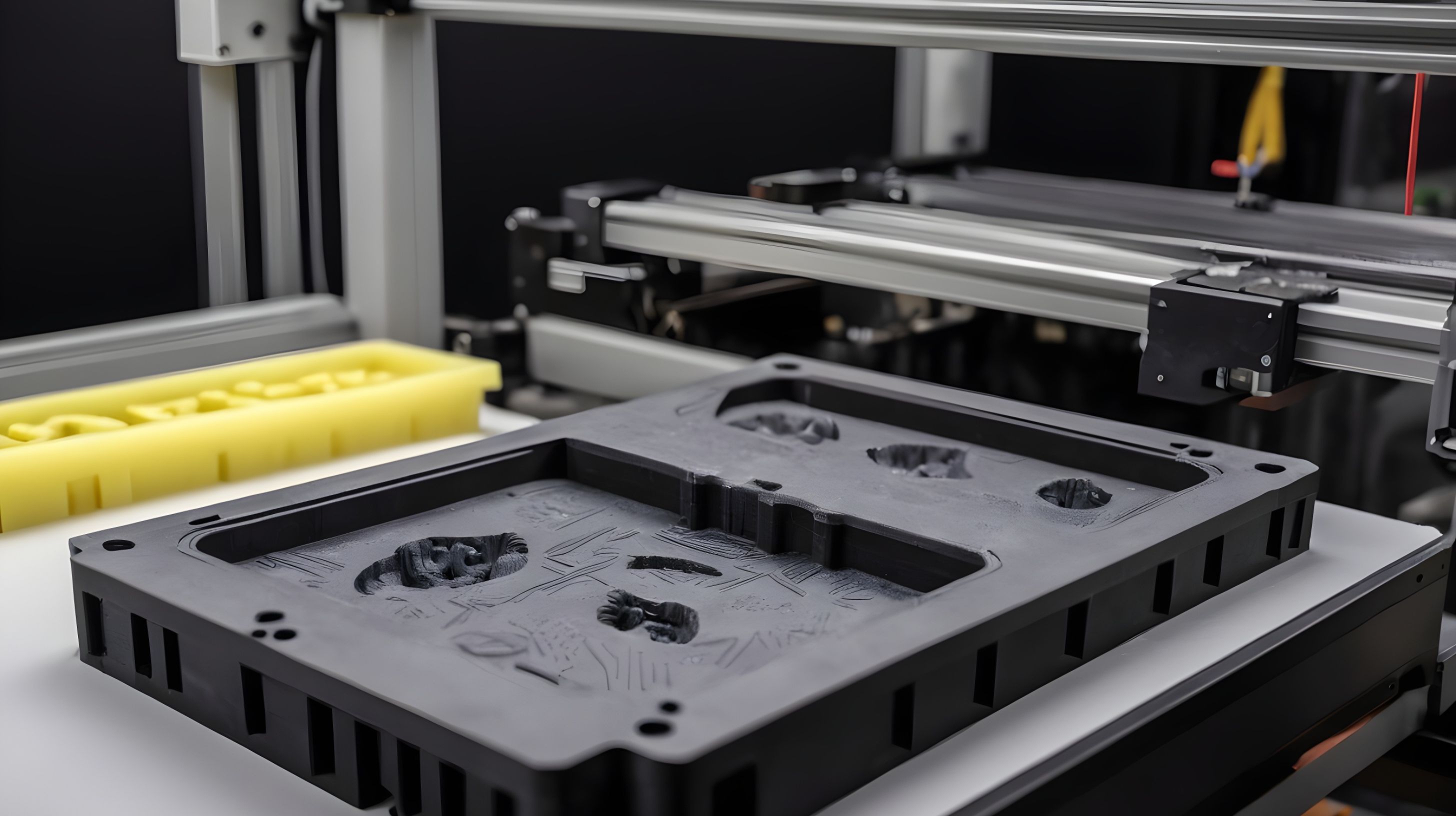

What are the benefits of 3D printing tooling and moulds?

Rapid Prototyping and Iterative Design

Traditional manufacturing methods may include time-consuming processes for generating moulds or tooling, resulting in longer lead times. 3D printing enables manufacturers to swiftly create prototypes and design iterations on demand, shortening the product development cycle and allowing for speedier responses to design changes.

Complex Geometry and Customization

3D printing allows for the creation of precise and complicated geometries in tooling and moulds that would be difficult or impossible to manufacture using older methods. This design flexibility enables the customisation of tools to meet specific manufacturing requirements. Manufacturers can produce highly customised moulds for unique product designs, increasing the efficiency and versatility of the manufacturing process.

Cost-Efficiency and Material Optimization

Additive manufacturing, including 3D printing, offers cost-effective solutions for producing tooling and moulds. Traditional methods often involve subtractive processes that generate significant material waste. In contrast, 3D printing builds objects layer by layer, minimising material usage and reducing waste. This efficiency not only contributes to cost savings but also aligns with sustainable manufacturing practices.

What are 3D printed tooling and mould applications?

Injection Moulding Tooling

These sophisticated and personalised moulds can be rapidly prototyped utilising 3D printing, enabling speedy design revisions and small batch production. The capacity to design complicated geometries improves the productivity and flexibility of injection moulding tooling.

Blow Moulding Tooling

3D printing is used to build moulds with complicated curves and contours in the blow moulding process for hollow plastic items. This application enables the creation of bespoke and lightweight containers, bottles, and other hollow plastic objects.

Vacuum Forming Moulds

Vacuum forming, which shapes plastic sheets, benefits from 3D-printed moulds. These moulds can be tailored for specific shapes and sizes, allowing for greater design freedom while minimising the lead time associated with traditional mould manufacture.

Casting Patterns

Three-dimensional printing is used to generate detailed patterns for metal casting operations. Foundries use 3D-printed patterns to create moulds for casting metal components with complex geometries, providing a more cost-effective and time-efficient alternative to traditional pattern-making techniques.

Composite Tooling

Moulds for composite material layup are created via 3D printing in the aerospace and automotive industries, which require lightweight and high-strength materials. These moulds enable the fabrication of lightweight components with complicated structures, which improves the overall efficiency of composite manufacturing processes.

Thermoforming Moulds

3D-printed moulds are useful for thermoforming, a procedure that uses heat and pressure to shape plastic sheets. These moulds can be tailored for a variety of applications, including packaging, automotive components, and consumer goods, allowing for greater design freedom and shorter lead times than traditional mould manufacture.

What materials do we recommend for 3D printing tooling and moulds?

Somos® PerFORM™ from Stratasys® - Printed on the Stratasys® Neo®800

Somos® PerFORM™ is the resin of choice for composite parts that need to be strong, stiff, and resistant to high temperatures. Somos® PerFORM™ is the appropriate material for tooling and moulds, due to its superior heat tolerance, detail resolution, and stiffness.

Parts created with Somos PerFORM™ have the lowest viscosity of any composite stereolithography material, making them faster to build, easier to post-process, superior in sidewall quality, and providing unrivalled detail resolution. Somos® PerFORM™ is a ceramic material with extremely high heat tolerance and rigidity.

The Stratasys® Neo®800 was designed with the customer in mind for reliable, gold standard industrial SLA 3D printing. Printing using the Somos® PerFORM on the Stratasys® Neo®800, produces dimensionally accurate parts with exceptional sidewalls and crisp feature resolution, resulting in a 50% reduction in finishing time.

Neo®800

Have your components 3D printed now! Do you have any questions? Contact our experts!

xCERAMIC3280 from Nexa3D® also known as Ultracur3D® RG 3280 from BASF - Printed on the Nexa3D® XiP Pro

Nexa3D® and BASF developed xCERAMIC3280 (Ultracur3D® RG 3280), a white ceramic composite resin that combines rigidity and high heat deflection with a ceramic look and feel, opening up new 3D printing possibilities for tooling and moulds.

The low viscosity of xCERAMIC3280 allows for incredibly quick printing, producing great detail and mechanical properties in minutes.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that are specifically made for the xCERAMIC3280 resin. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of high-temperature resistant components with high resolution in a matter of hours.

XiP Pro

Have your components 3D printed now! Do you have any questions? Contact our experts!

xPEEK147 from Nexa3D® also known as IND147 from LOCTITE 3D - Printed on the Nexa3D® XiP Pro

xPEEK147 is a high-temperature-resistant resin with an HDT of 230°C and exceptional dimensional stability for low-load moulding applications. xPEEK147 has a good surface finish and enough toughness to withstand mechanical pressures during moulding processes.

Its distinctive qualities make it perfect for applications like silicone and polyurethane moulding.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that can utilise the xPEEK147 from Nexa3D® also known as IND147 from LOCTITE 3D resin well. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of high-temperature resistant parts with high resolution in a matter of hours.

XiP Pro