Evonik INFINAM® PEEK

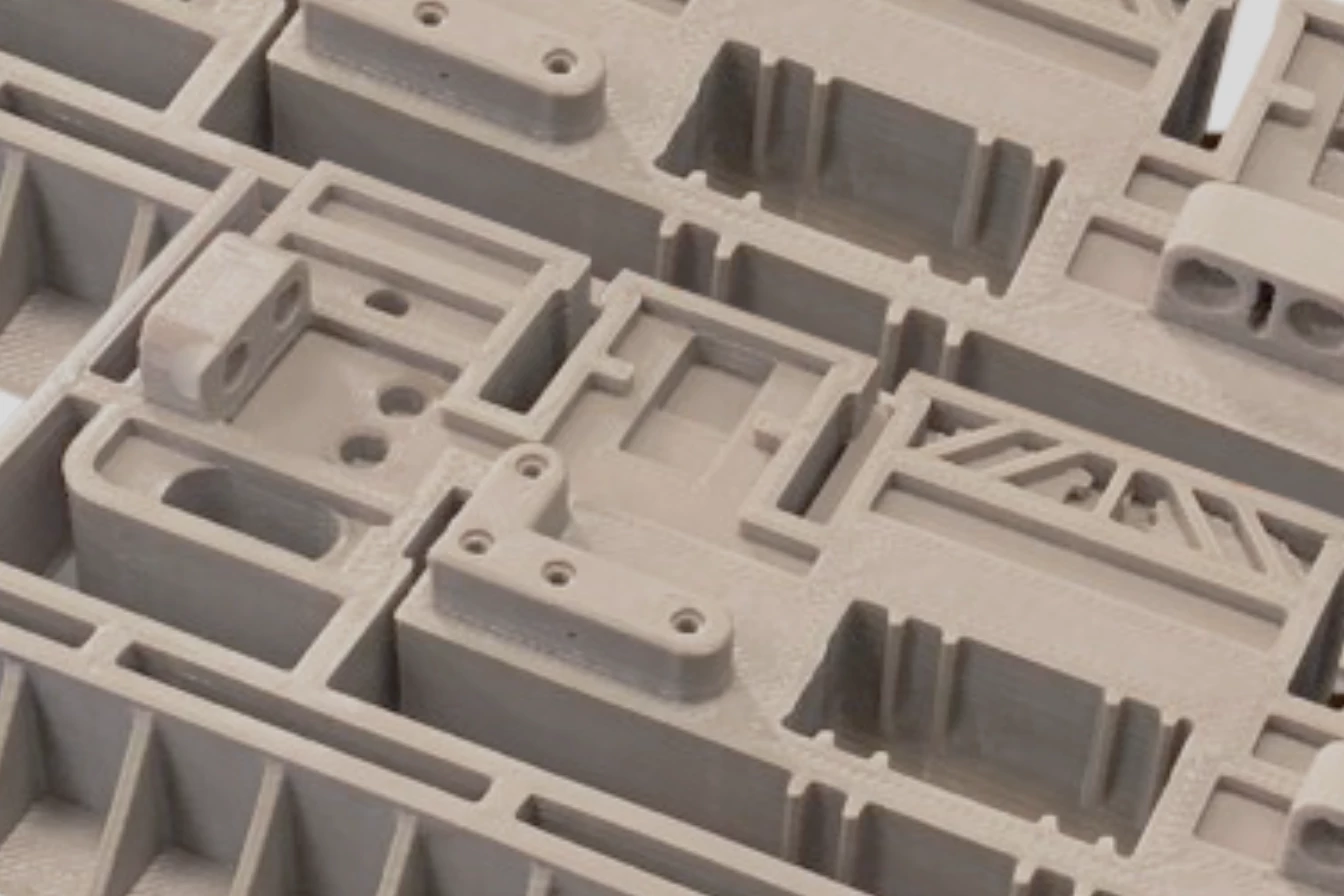

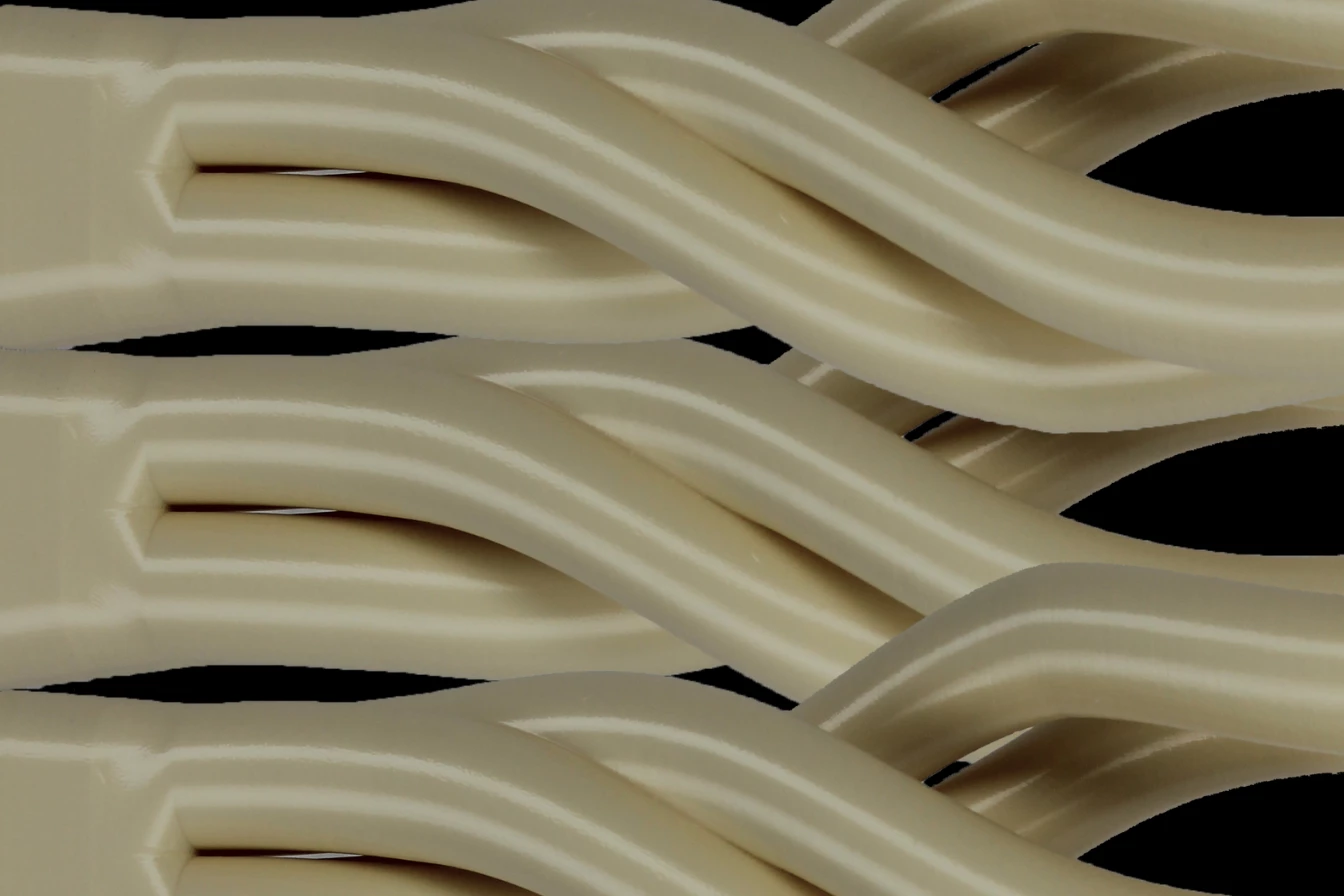

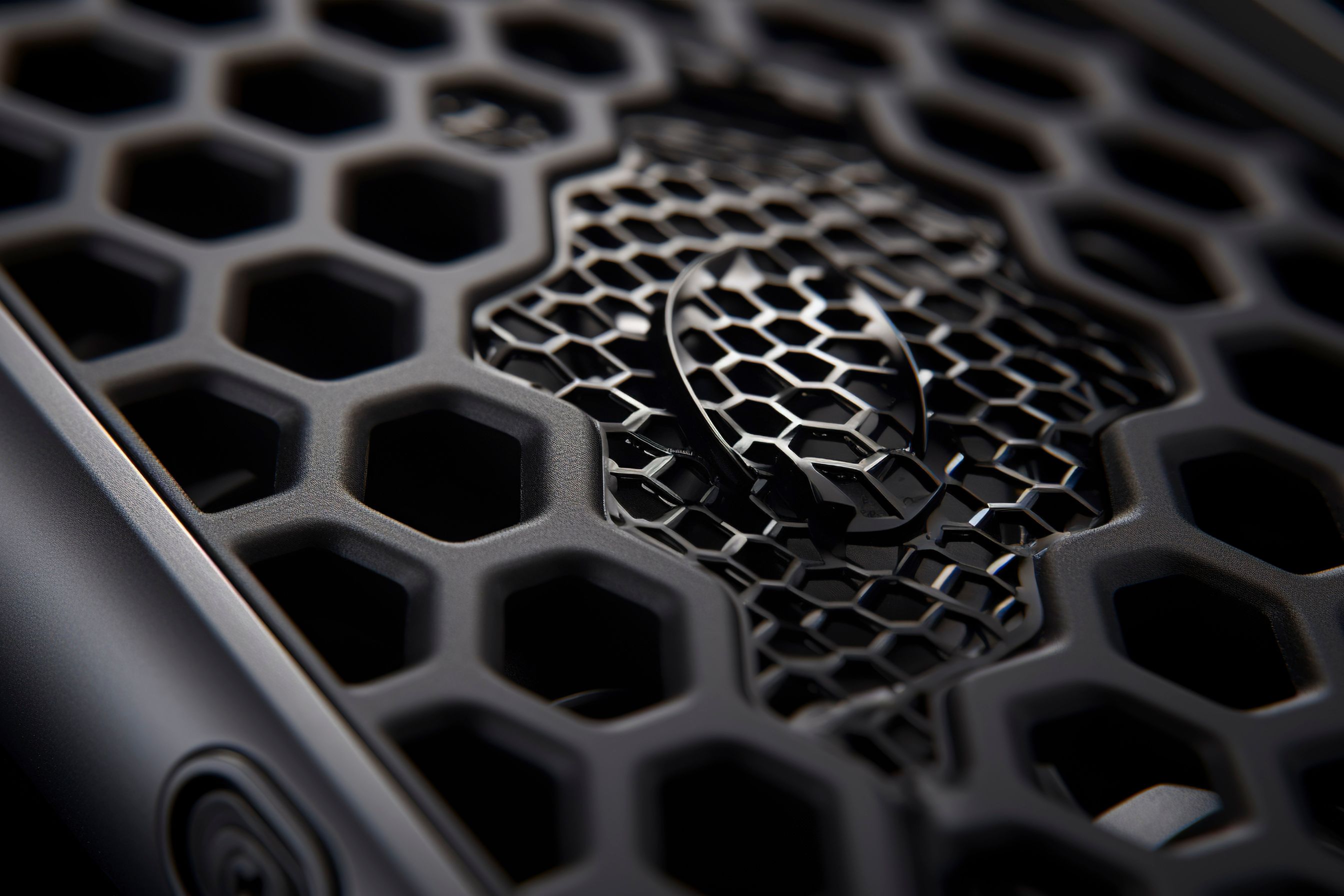

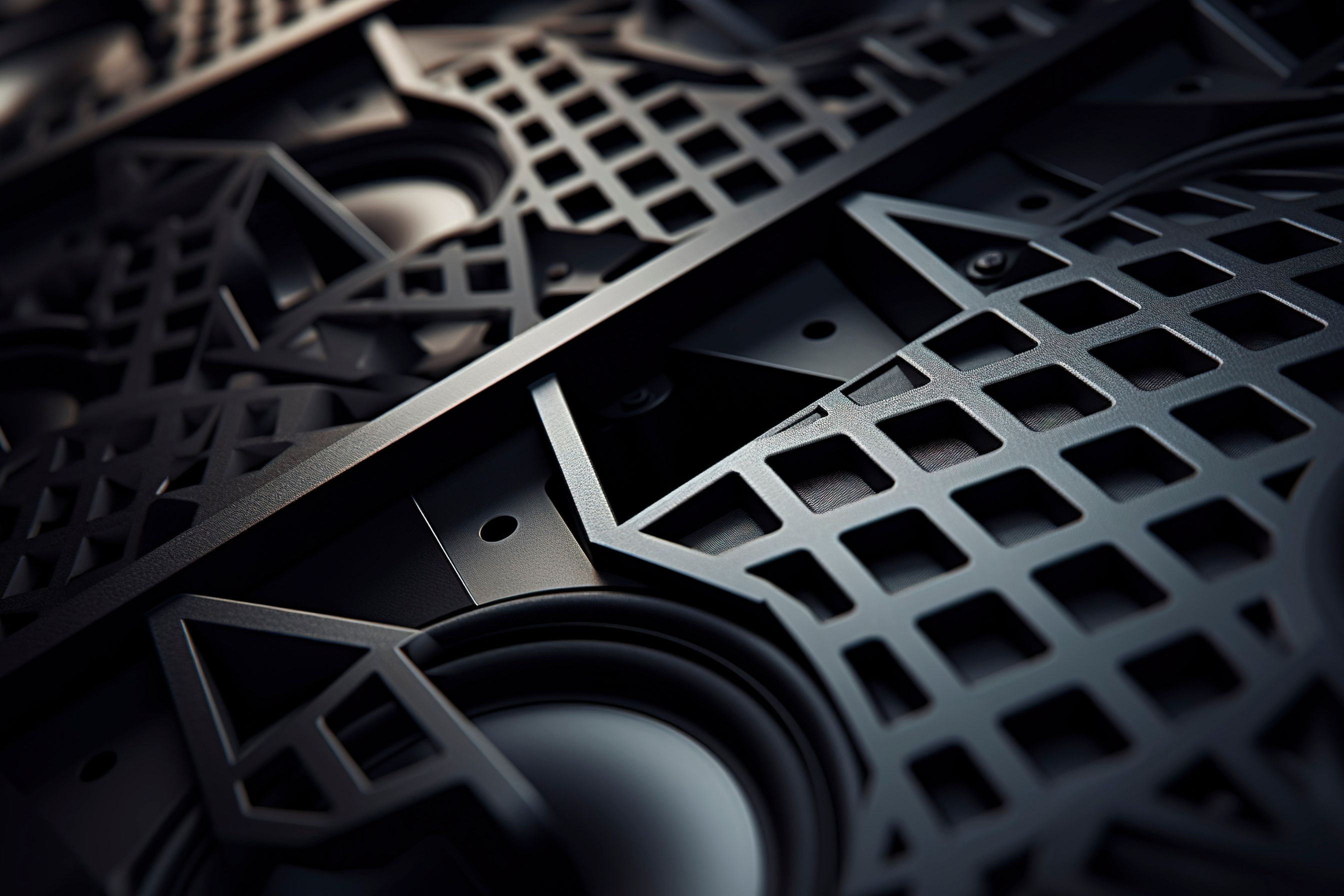

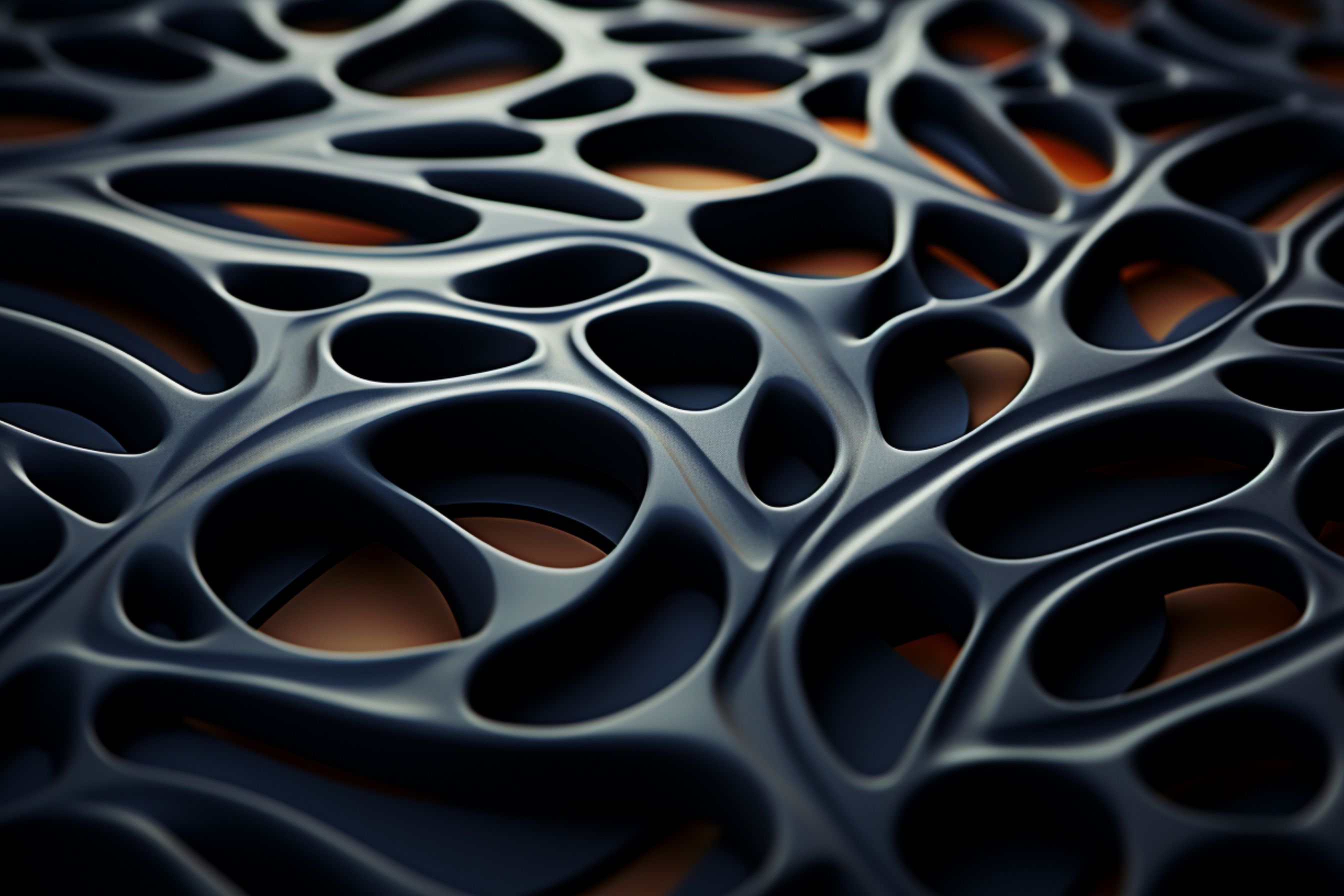

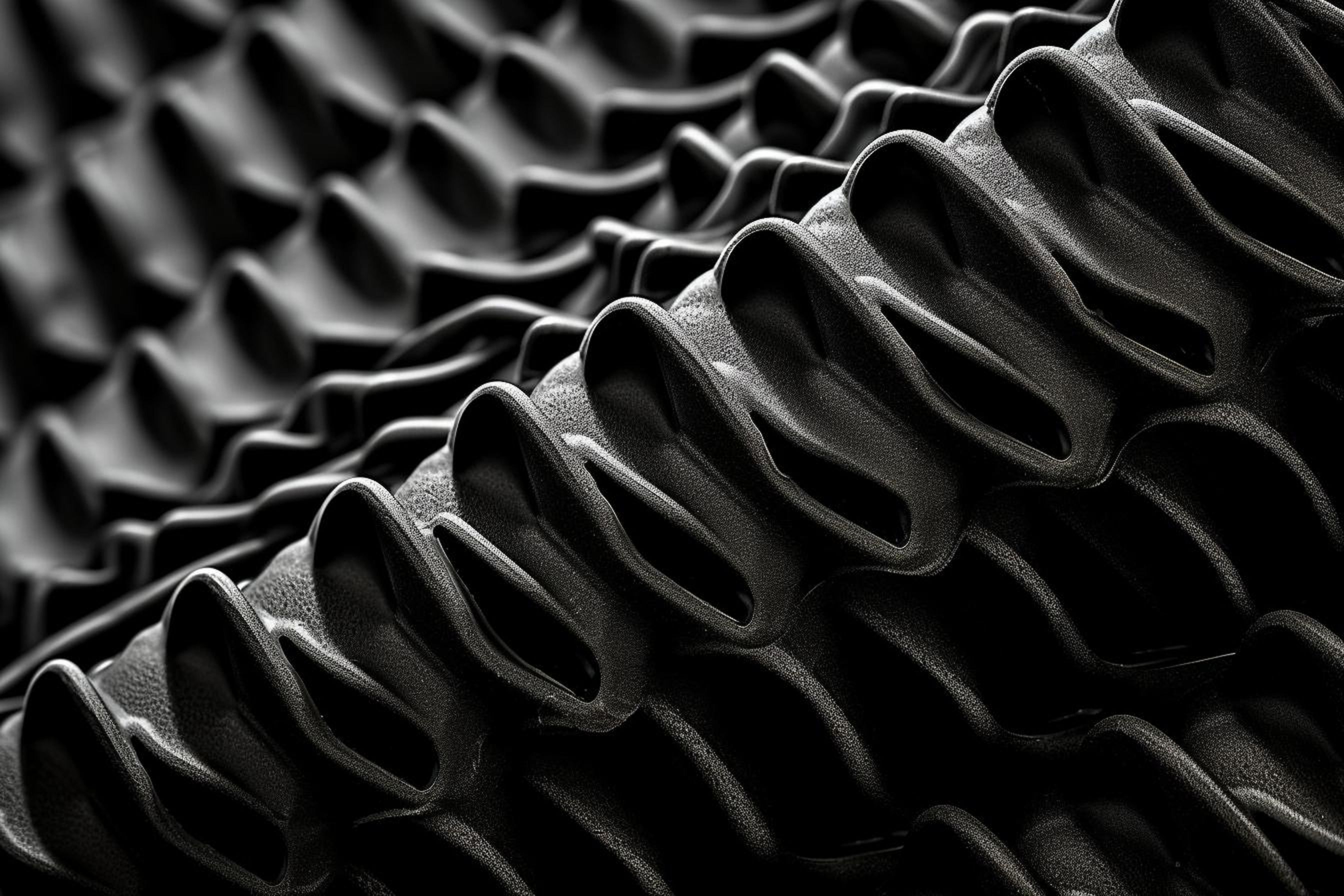

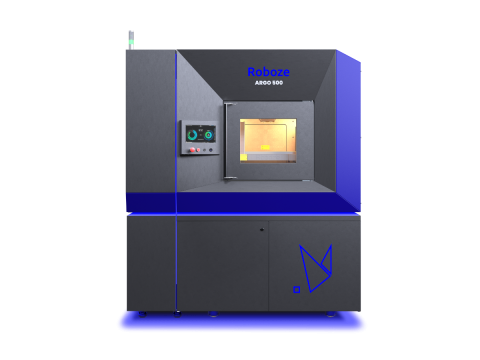

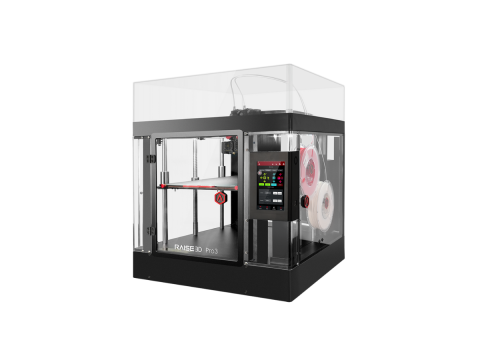

Evonik has developed a new 3D printable filament based on PEEK (polyether ether ketone). The high-temperature and chemical-resistant ready-to-use material is particularly suitable for the additive manufacturing of demanding industrial plastic parts. The high-performance polymer can be processed in common extrusion-based 3D printing technologies such as fused filament fabrication (FFF) or fused deposition modeling (FDM).

- High-temperature resistant PEEK material extends product portfolio

- Ready-to-use polymer filament as metal replacement for infinite industrial 3D applications

- INFINAM® PEEK can be used in common extrusion-based 3D printing technologies (FFF/FDM)