What is prototyping?

Prototyping is the process of developing a preliminary version of a product, system, or concept in order to test and assess its design, functionality, and viability. Prototypes are real or virtual models that depict the desired final product. The primary goal of prototyping is to collect input, uncover potential design faults, and validate concepts early in the development cycle. It enables designers, engineers, and stakeholders to evaluate a product's functionality and performance before investing in full-scale manufacturing, reducing risks and optimising the final design through iterative testing and refining. Prototyping is an important step in the product development process across sectors, allowing for the exploration of ideas while ensuring that the final product fits the desired specifications and user expectations.

What important features should prototypes have?

Fidelity to the Original

To shorten iteration processes and correctly identify potential design errors, maximum fidelity to the original design is essential. This fidelity to the original enables exact testing of form, fit and functionality, resulting in more effective validation of the prototype.

Iterative and Customizable

Prototypes should facilitate iterative design processes, allowing for quick changes and updates based on feedback. Customizability is critical for accommodating design modifications and revisions throughout the prototyping phase.

Material Appropriateness

The materials used in prototypes must be carefully selected. It should be consistent with the intended production materials in order to accurately imitate the physical qualities of the finished product. This consideration is especially relevant for functional testing and validation.

Cost-effective and Time-efficient

Prototyping techniques should find an optimum between cost efficiency and time efficiency. Rapid prototyping strategies serve to reduce time and costs and allow designers to quickly optimize in multiple iterations without significant financial or time investment.

User-oriented

Prototypes lay the foundation for a perfect end product. This is why the end user must be at the center of this first step of the product development cycle. Prototypes are the ideal way to identify difficulties with user-friendliness at an early stage.

Scalability Considerations

Rapid scalability is essential for series production. In order to be able to react to changing market conditions at an early stage, intensive validation of scalability is necessary as early as the prototyping phase in order to identify potential hurdles and bottlenecks at an early stage.

What are the benefits of 3D printing prototypes?

Rapid Iteration and Design Optimization

One of the most significant advantages of 3D printing in prototyping is its ability to enable quick iteration and design optimization. Traditional prototyping approaches can require lengthy and resource-intensive processes, making it difficult to incorporate design changes fast. 3D printing enables designers and engineers to quickly create prototypes and iterate through several variations. This iterative design approach helps to improve product development processes and reduce time-to-market.

Cost-effectiveness and Material Optimization

3D printing optimizes material utilization through a layer-by-layer additive manufacturing process, resulting in less waste than subtractive processes. This not only makes prototyping more affordable, but it also allows for the research of various materials without incurring major financial costs. The capacity to construct prototypes with specified material qualities helps to provide a more exact depiction of the final product, which aids in functional testing and validation.

Complex Geometry and Intricate Details

Traditional prototype methods may struggle to represent the precise features and complicated geometry found in modern product ideas. 3D printing shines in this area, allowing for the manufacture of prototypes with remarkable precision. From complicated architectural models to complex mechanical parts, 3D printing enables designers to accurately transfer intricate computer concepts into tangible prototypes, enabling a closer alignment of the virtual and physical worlds.

What are the industry applications of 3D printing prototypes?

Engineering and Product Design

Designers can swiftly convert digital designs into physical prototypes, allowing for hands-on testing of form, fit, and function. This is especially useful in the development of consumer goods, manufacturing, and new gadgets, where physical characteristics are critical to success.

Medical Prototyping

Custom implants, patient-specific anatomical models, and medical devices can be quickly prototyped, providing surgeons and medical workers with a physical representation for pre-surgical planning and training. The capacity to develop complex, patient-specific models aids advancements in personalised treatment.

Automotive Prototyping

Automotive firms use 3D printing to prototype a variety of components, ranging from intricate engine parts to full vehicle models. Prototyping with 3D printing enables the testing of design concepts, ensuring that components fit flawlessly and fulfill performance standards before mass production. This iterative technique helps to refine car designs and increase overall efficiency.

Aerospace Prototyping

In aerospace, where precision and lightweight components are crucial, 3D printing is widely used for prototyping. The technology enables the fabrication of complicated and lightweight components, which helps with the development and testing of aircraft parts, propulsion systems, and satellite components.

What materials do we recommend for prototyping using 3D printing?

Somos® WaterShed® XC 11122 from Stratasys® - Printed on the Stratasys® Neo®800

Somos® WaterShed® XC 11122 is a popular resin among manufacturers due to its ABS and PBT-like qualities for stereolithography technology. Somos® WaterShed® provides detailed parts with high clarity and water resistance, making them ideal for prototyping among many other things.

The robust, clear parts have the look and feel of manufactured plastic, with a smooth finish that speeds up testing.

The Stratasys® Neo®800 is ideal for those who need high-definition prototypes for their applications. Using the Neo®800 to print the Somos® WaterShed® XC 11122 allows you to quickly produce SD or HD prototypes with fine resolution and intricate, small details.

Neo®800

Have your components 3D printed now! Do you have any questions? Contact our experts!

Somos® WaterShed® Black from Stratasys® - Printed on the Stratasys® Neo®800

Somos® WaterShed® Black, a stereolithography resin, has identical qualities and processing to Somos® WaterShed® XC 11122. It produces hard, durable parts in a true black colour without painting.

Somos® WaterShed® Black's enhanced formulation allows for up to 50% faster processing than competing black SL materials, requiring less finishing and providing more uniform processing over time. Somos® WaterShed® Black also has excellent moisture and chemical resistance making it perfect for prototyping among many other things.

The Stratasys® Neo®800 is ideal for those who need large high-definition prototypes for their applications. Using such a machine to print the Somos® WaterShed® Black from Stratasys® allows you to quickly produce large-format SD and HD prototypes with fine resolution and intricate, small details.

Neo®800

Have your components 3D printed now! Do you have any questions? Contact our experts!

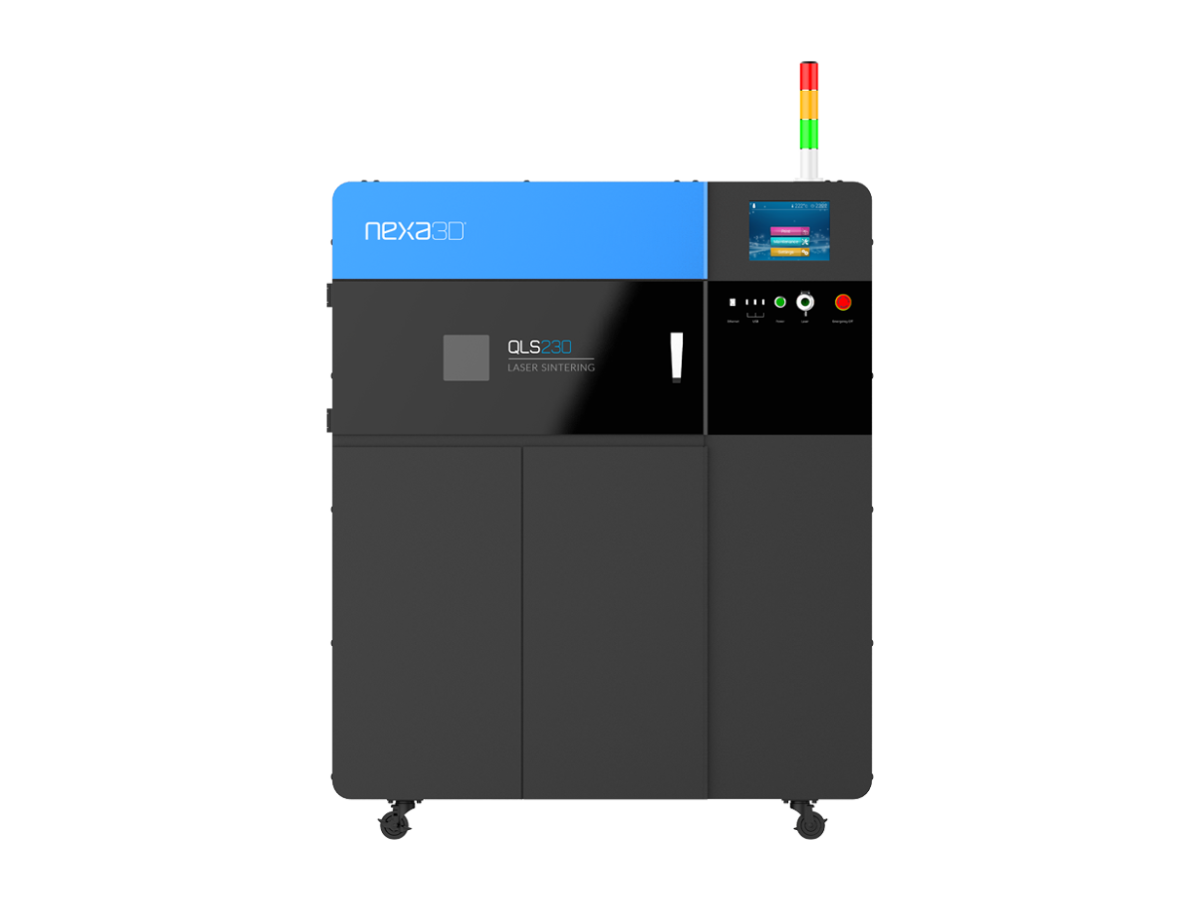

PTG PA12 from ProductionToGo - Printed on the Nexa3D® QLS 820

PTG PA12 is a high-performance polymer with superior detail fineness and surface resolution. It also has excellent mechanical qualities and resistance to a variety of chemicals.

The PTG PA12 can be used for prototyping and even for medical devices with temporary physical contact.

A variety of printers, including the powder 3D printers of Nexa3D® such as the QLS 230, QLS 236, QLS 260, QLS 820, and the Stratasys® H350, can print this material with precision without the use of supports, allowing you to design prototypes with complicated structures.

QLS 820

QLS 260

QLS 236

QLS 230

H350™

Have your components 3D printed now! Do you have any questions? Contact our experts!

INFINAM® RG 3101 L from Evonik - Printed on the Nexa3D® XiP Pro

INFINAM® RG 3101 L is a black, low-viscosity photopolymer that cures quickly and is very easy to process. The ready-to-use material combines excellent impact strength with high temperature resistance and exhibits long-lasting thermomechanical performance.

This photopolymer can be exposed to strong forces due to its high breaking strength. It can replace some of the engineering plastics produced by traditional processes and is perfect for creating prototypes among many other things.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that can utilise the INFINAM® RG 3101 L resin best. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of models and prototypes with high resolution in a matter of hours.

XiP Pro

Have your components 3D printed now! Do you have any questions? Contact our experts!

xABS3843 Black from Nexa3D® - Printed on the Nexa3D® XiP Pro

Nexa3D 3843-xABS Black is a high-performance, high-modulus material with good flexural and tensile capabilities and a reasonably high degree of elongation. Nexa3D 3843-xABS Black has strong green strength and a low heat deflection temperature, allowing it to print properly and work in a wide range of applications.

Nexa3D 3843-xABS Black was evaluated under QUV external weathering conditions (ASTM G-154) for 800 hours and showed less than a 15% change in Tensile and IZOD Impact characteristics.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that are specifically made for the 3843-xABS Black resin. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of parts with high resolution in a matter of hours.

XiP Pro

Have your components 3D printed now! Do you have any questions? Contact our experts!

ABS-M30 from Stratasys® - Printed on the Stratasys® F770

ABS-M30 introduces the familiarity and versatility of ABS (acrylonitrile butadiene styrene) to the FDM 3D printing plastics range. It is an excellent material for a variety of applications such as form and fit testing and functional prototyping.

ABS-M30 is distinguished by its strength and toughness while remaining lightweight and robust. ABS-M30 is the best choice for general-purpose 3D printing due to its usability and cost-effectiveness.

The F770 FDM 3D printer has one of the largest print volumes among the Stratasys® FDM systems. This printer combined with the ABS-M30 filament from Stratasys® lets you create massive parts or vast collections of smaller parts with the requirements you need.

F770™

Have your components 3D printed now! Do you have any questions? Contact our experts!

ASA from Stratasys® - Printed on the Stratasys® F770

ASA filament (acrylonitrile styrene acrylate) is the ideal all-purpose 3D printing thermoplastic, suited for a wide range of applications. It has the same chemical makeup as ABS plastic but has three advantages: greater mechanical qualities, higher aesthetics, and UV resistance.

ASA material is also available in ten colours, more than any other FDM material and is perfect for end-products and prototyping among many other applications.

The F770 FDM 3D printer offers one of the biggest print volumes among all Stratasys FDM systems. This printer, when combined with Stratasys® ASA filament, allows you to manufacture large parts or vast collections of smaller parts that meet your specific requirements.

F770™