What does “medical” and “biocompatibility” imply in 3D printing?

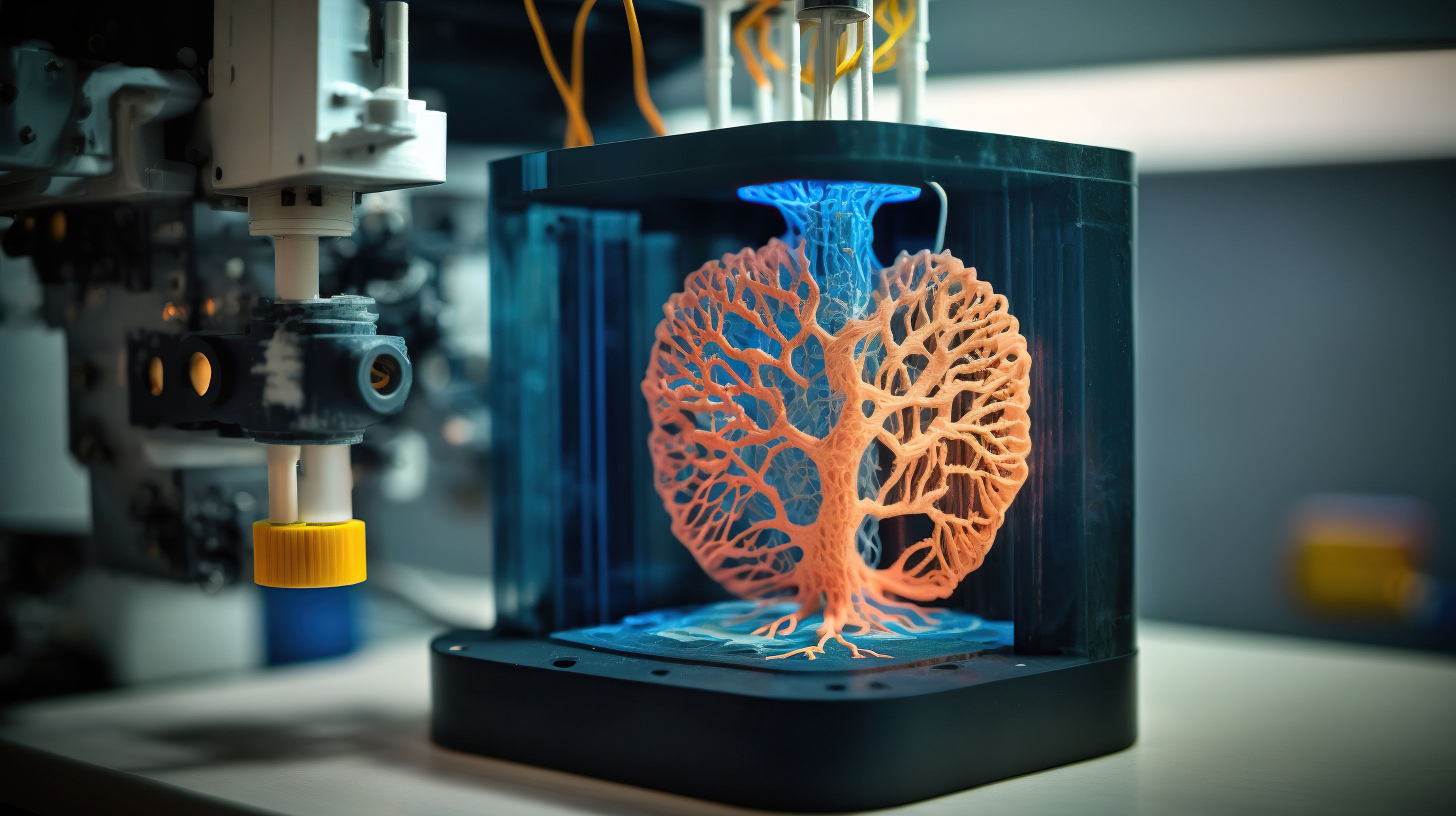

In the context of 3D printing, the term "medical" refers to the use of additive manufacturing technologies and processes in healthcare and medicine. This involves using 3D printing to create personalised medical devices, patient-specific implants, anatomical models for surgical planning, prosthetics, dental applications, and other healthcare-related components. Medical 3D printing seeks to address issues in traditional medical procedures by providing personalised solutions, increasing treatment outcomes, and advancing different elements of patient care, surgery, and biological research.

In the context of 3D printing, “biocompatibility” refers to the capacity of additive manufacturing materials to interact with biological tissues and organisms without causing harm or provoking undesirable reactions. Biocompatible materials are intended to interact safely with the human body, increasing acceptance and integration when utilized in applications such as medical implants, prosthetics, and other healthcare devices. These materials should have qualities that do not cause toxic responses, inflammation, or rejection when in touch with biological systems, making them suitable for medical and biocompatible 3D printing applications.

What are the benefits of 3D printing in medical applications?

Patient-specific Customization

Medical experts can use imaging data to create personalized implants, prosthetics, and anatomical models based on each patient's unique anatomy. This level of customisation improves the fit, comfort, and effectiveness of medical procedures, resulting in better patient outcomes.

Advanced Surgical Planning and Training

3D printing makes it easier to create detailed anatomical models, allowing surgeons to plan and rehearse complex treatments before going into surgery. These 3D-printed models allow doctors to view patient anatomy, identify potential problems, and enhance surgical techniques. Furthermore, medical practitioners can use 3D-printed models for training, improving their abilities and knowledge in a risk-free setting.

Innovative Research and Development

Researchers can employ additive manufacturing to build prototypes of innovative medical equipment, implants, and medications. The technique enables quick design iteration and testing, which accelerates the invention cycle in fields such as drug delivery systems, tissue engineering, and regenerative medicine. This encourages ongoing progress and the creation of innovative medical solutions.

What are the applications of 3D printing in the medical industry?

Biocompatible Implants and Devices

Orthopedics: 3D printing has transformed orthopedic procedures by enabling the development of biocompatible implants that are personalized to each patient's anatomy. Implants for joint replacement, spinal operations, and bone repair are made from materials such as titanium alloys and biocompatible polymers. The tailored nature of these implants increases compatibility, lowers the chance of rejection, and improves overall patient outcomes.

Dental: Biocompatible materials play an important part in dental applications, as 3D printing is used to create custom-fit dental implants and prosthesis. Resin-based materials and biocompatible metals ensure that these implants merge easily with the surrounding tissues, offering patients with long-lasting and natural-looking solutions.

Patient-Specific Surgical Models and Guidelines

Pre-surgical Planning: 3D printing makes it easier to create highly accurate anatomical models for patients based on medical imaging data. These models benefit surgeons in pre-surgical planning by providing a thorough understanding of the patient's specific anatomy. Biocompatible materials ensure that models adequately mimic tissue qualities, allowing surgeons to practice and modify procedures before going into the operating room.

Surgical guides: Biocompatible 3D-printed surgical guides are employed in a variety of medical fields, including orthopedics and maxillofacial surgery. These instructions help surgeons properly place implants or perform difficult surgeries. These guides' biocompatibility assures that they have minimal influence on adjacent tissues and improves surgical intervention precision.

Customized Prosthetics and Wearables

Prosthetic limbs: 3D printing allows for the customization of prosthetic limbs utilizing biocompatible materials. This not only assures a comfortable fit for the patient, but also enables the insertion of sophisticated designs and functional elements. These prosthetics are lightweight and durable, which improves amputees' mobility and overall quality of life.

Biocompatible wearables: Biocompatible materials in 3D printing can be used to create wearable medical devices as well. Patient-specific wearables, such as hearing aids and orthopedic braces, can be 3D printed with materials that are not only biocompatible, but also flexible and customized to the individual's needs.

What materials do we recommend for medical 3D printing?

INFINAM® ST 6100 L from Evonik - Printed on the Nexa3D® XiP Pro

INFINAM® ST 6100 L is a high-performance material that unlocks the potential of medical additive manufacturing. INFINAM® ST6100 L sets new standards in the high-strength photopolymer resin category with a combined tensile strength of 89 MPa, flexural stress of 145 MPa and HDT of 120 °C, closing the material gap in ultra-high-strength photopolymers.

These special material properties make INFINAM® ST 6100 L the material of choice for applications requiring high temperature resistance combined with high mechanical strength.

The XiP Pro printer from Nexa3D® is one of the ultra-fast resin 3D printers that is highly capable in printing resins with ISO10993 from Evonik. The unique LSPc® technology of Nexa3D® allows for the rapid manufacture of biocompatible parts with high resolution in a matter of hours.

XiP Pro

Have your components 3D printed now! Do you have any questions? Contact our experts!

PTG PA12w from ProductionToGo - Printed on the Nexa3D® QLS 820

PTG PA12w is a high-performance polymer with superior detail fineness and surface resolution. It also has excellent mechanical qualities and resistance to a variety of chemicals.

The PTG PA12w can be used for a wide range of medical devices with temporary physical contact.

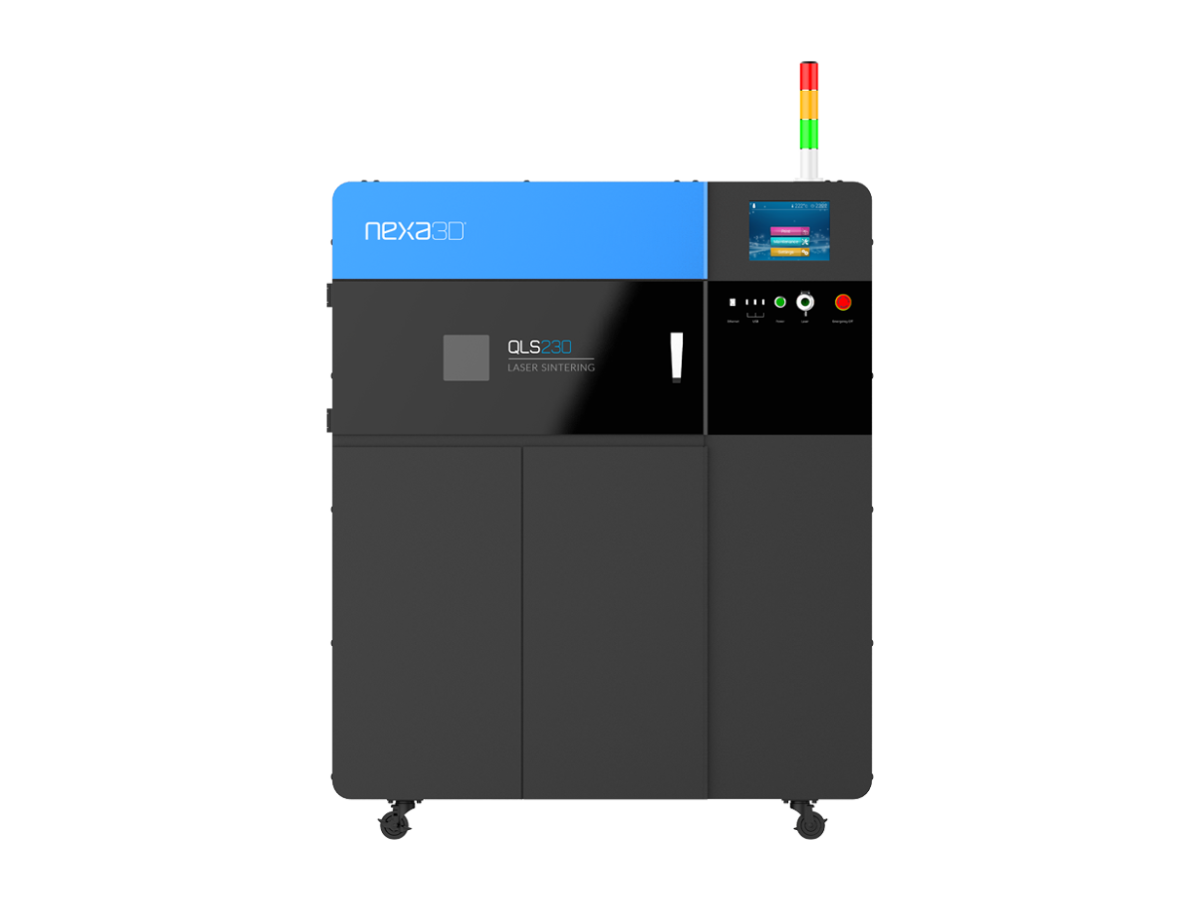

A variety of printers, including the powder 3D printers of Nexa3D® such as the QLS 230, QLS 236, QLS 260, QLS 820, and the Stratasys® H350, can print this material with precision without the use of supports, allowing you to design complicated structures.

H350™

QLS 820

QLS 260

QLS 236

QLS 230