What is the maritime industry?

A wide range of operations involving the sea and waterborne commerce are what defines the "maritime" industry. It covers the movement of people and products across water and involves shipping, maritime transportation, and logistics. In addition, the sector includes shipbuilding, ship repair, and ship scrapping activities, as well as navigation, marine engineering, and vessel operations. The industry includes fishing and seafood processing as integral parts in addition to passenger water transportation services such as cruise ships and ferries. Important components also include port operations and related services. Approximately 90% of world trade is transported by sea, making the marine sector a significant component of global trade.

What are the 3 main divisions in the maritime industry?

Military Maritime Division

Naval operations and vessels utilised for military and national defence are included in this area. It consists of destroyers and battleships, submarines, aircraft carriers, amphibious assault ships, patrol boats and coastal defence vessels. Highly specialised warships built for fighting, surveillance, and strategic missions define the military maritime industry.

Commercial Maritime Division

The largest and most varied industry is the commercial maritime division, which includes ships used for trade, transportation, and other commercial endeavours. This section consists of passenger ships and cruise ships, ships carrying cargo (bulk carriers, tankers, and container ships), river cruise ships and ferries, fishing vessels and offshore support vessels for the gas and oil sectors. This industry is essential to world trade and economics.

Private Use Maritime Division

This division handles watercraft for personal and recreational usage. It consists of motorboats, sailing yachts, racing yachts, personal watercraft (jet skis, etc.) and small fishing boats. Water sports with canoes, kayaks and diving equipment also fall into this category.

What are the important part characteristics to be considered when creating parts for the maritime industry?

Corrosion resistance

Components need to be able to resist being exposed to seawater and hostile maritime conditions. It is essential to use corrosion-resistant materials, such as marine-grade aluminium, stainless steel, Bronze or special composite materials and plastics.

Durability

Marine parts must withstand harsh circumstances such as high humidity, abrupt temperature changes, and continuous motion. They need to be resilient to extended strain and exhaustion.

Weight optimization

Robust materials with ideal weight distribution are needed to increase the fuel efficiency and overall performance of the ship. This is where the major benefits of additive manufacturing can be realised.

Weather resistance

Items must be able to endure extended exposure to wind, UV rays, and temperature changes without degrading.

Compliance with safety requirements

Parts have to adhere to strict marine safety guidelines established by agencies such as the International marine Organization (IMO).

Waterproofing

For many components to work effectively in maritime situations, they must be water-resistant or waterproof.

Scalability

In order to suit varying vessel sizes or requirements, parts should be constructed with the capacity to be easily scaled.

Maintainability

To reduce vessel downtime, components should be made to be simple to maintain, repair, or replace.

Design flexibility

When utilising AM, the capacity to design intricate geometries that combine several functionalities into a single item is invaluable. This means that customer-specific requirements can also be ideally fulfilled.

What are the benefits of 3D printing in the Maritime Industry?

On-demand production

Even in remote places like ships at sea, parts may be made on demand thanks to 3D printing. Manufacturers and service technicians can keep digital files for legacy parts, allowing them to print on-demand and keep older equipment operational, even when original parts are no longer commercially available. This makes it possible to do quick repairs and eliminates the need to keep big spare component inventories and waiting periods.

Design flexibility

The technology makes it simple to produce complex shapes that would be challenging to customise using conventional techniques. 3D printing facilitates quick design iterations and prototyping, speeding up the development process. Parts can be designed to be lighter while maintaining strength, improving vessel efficiency.

Environmental impact

When compared to conventional processes, additive manufacturing yields a significant reduction in material waste. 3D printing uses only the material needed for the part, reducing waste compared to subtractive manufacturing processes. In certain circumstances, it also permits the use of recycled materials, in line with sustainability objectives.

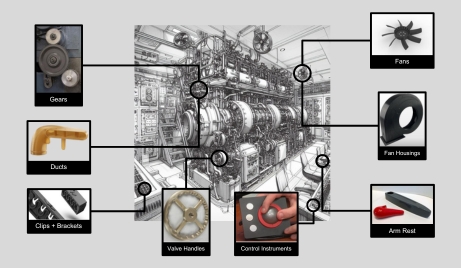

What are the applications of 3D printing in the maritime industry?

Rapid Prototyping and Model Making

Using this technology, naval architects and designers can now produce scale models of ships and yachts that are incredibly realistic and detailed. Before going into full-scale manufacturing, these models help engineers visualize and improve their concepts, which is why they are so important for design testing. For example, it is possible to swiftly 3D print submarine prototypes, which allows for faster design revisions and advancements. This application speeds up the entire ship design process by drastically cutting down on the time and expense involved in traditional model-making techniques.

On-demand Spare Parts Production

Nowadays, 3D printers can be installed on ships, enabling them to create replacement parts whenever they're needed, even in far-off places at sea. This capacity removes the need to carry large inventory of spare parts and significantly reduces downtime. The US Navy's use of 3D printing for submarine spare parts is one noteworthy example. By ensuring that essential parts are constantly available, this strategy improves operational preparedness and lessens the logistical difficulties that come with using traditional supply chains.

Custom and Complex Technical Components

Complex objects that would be difficult or impossible to make using conventional methods can now be produced thanks to 3D printing. Examples include 3D printed boat propellers tuned for particular performance characteristics, and fuel-efficient injection nozzles for ship engines. The total performance and efficiency of the vessel can be increased by customising these parts to meet precise standards.

Equipment for Underwater Missions

Deepwater monitoring equipment components and parts for autonomous underwater vehicles (AUVs) are being produced using 3D printing. The ability to make components that are strong and resistant to the intense pressures found in deep-sea conditions is advantageous for these applications. 3D printing, for instance, is being used by businesses like ecoSUB Robotics to create high-quality, reasonably priced underwater vehicles for deep surveillance missions, demonstrating the adaptability of this manufacturing process in specific maritime applications.

Tooling and Fixtures

Fast custom fixture and jig manufacture is made possible by 3D printing and is utilised in shipbuilding and repair operations. The speed at which these tools can be created and manufactured to suit particular needs enhances the accuracy and efficiency of maritime production. For example, shipyards are able to design complex assembly jigs or specialised holding fixtures for welding processes based on the specific geometry of various vessel components.

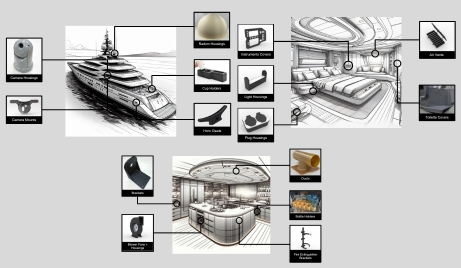

Exterior and Interior Boat Components

With regard to external components, it is possible to design robust, weatherproof camera and radome housings and mounts that can be customised to fit certain equipment and positions aboard the ship. It is also possible to have horn cleats and cup holders made specifically to fit the boat's practical needs and style preferences.

Inside the boat, custom light and plug housings guarantee a unified interior appearance, and instrument covers can be made to fit precisely over a variety of gauges and displays. It is also possible to create air vents that complement the interior design of the boat and customised toilet covers that enhance both appearance and hygiene.

What materials do we recommend for 3D printing in the maritime industry?

As a responsible 3D printing service provider, we prioritise our parts' safety, dependability, and performance in maritime environments. As a result, we only propose materials that have passed the stringent IACS E10 testing for Salt Mist (Test No. 12), Cold (Test No. 11), and Flame Retardancy (Test No. 21). This demanding technique assures that our 3D printed components can endure the severe marine environment, which includes salt-laden air, freezing temperatures, and potential fire threats. By adhering to these standards, we ensure compliance with marine legislation, improve operational reliability, and reduce the likelihood of early breakdowns.

Our commitment to using only tested and approved materials demonstrates our commitment to providing high-quality, long-lasting solutions that address the maritime industry's unique challenges, ultimately ensuring the safety of vessels and crews while optimising long-term cost-effectiveness for our clients.

FDM Nylon 12CF (Carbon Fiber) from Stratasys® - Printed on the Stratasys® Fortus® 450mc

FDM Nylon 12CF (Carbon Fiber) from Stratasys® has the best flexural strength among FDM thermoplastics, resulting in an extraordinary stiffness-to-weight ratio, which is critical for maritime applications that require weight reduction and structural integrity.

Its high fatigue resistance makes it perfect for components subjected to repetitive stress, vibrations, and regular use in marine conditions. The high chemical resistance of Nylon 12CF is especially useful for parts that are exposed to seawater and other marine pollutants.

Salt Mist (Test No. 12): Pass

Cold (Test No. 11): Pass

Flame Retardancy (Test No. 21): Pass

The Fortus® 450mc provides precise, dependable performance, allowing you to revolutionise supply chains, speed manufacturing, and save production costs. Its proven reliability and capability to use the FDM Nylon 12CF (Carbon Fiber) from Stratasys® makes it a trusted 3D printing solution for maritime applications.

Fortus® 450mc

Have your components 3D printed now! Do you have any questions? Contact our experts!

ASA from Stratasys® - Printed on the Stratasys® Fortus® 450mc

ASA (acrylonitrile styrene acrylate) from Stratasys® provides good UV stability and is essential for maritime components exposed to direct sunshine, as it helps retain mechanical qualities and appearance over time.

ASA's high resilience to weathering, including moisture and temperature variations, makes it ideal for outdoor marine applications. Its chemical resistance is useful in environments where exposure to numerous chemicals is common. The material's dimensional stability provides part correctness in the many environmental conditions found at sea.

Salt Mist (Test No. 12): Pass

Cold (Test No. 11): Pass

Flame Retardancy (Test No. 21): Pass

The Fortus® 450mc provides precise, dependable performance, allowing you to revolutionise supply chains, speed manufacturing, and save production costs. Its proven reliability and capability to use the ASA from Stratasys® makes it a trusted 3D printing solution for maritime applications.

Fortus® 450mc

Have your components 3D printed now! Do you have any questions? Contact our experts!

ULTEM™ AM9085 from Stratasys® - Printed on the Stratasys® F900

ULTEM™ AM9085 filament is a high-performance thermoplastic with exceptional physical and mechanical qualities, ideal for high-demand and specialist applications such as for the maritime industry. It is one of the strongest Stratasys® FDM materials, and its high strength-to-weight ratio makes it ideal for high-strength, low-weight applications.

ULTEM™ AM9085 filament has strong impact resistance, excellent chemical tolerance, and meets various industry standards for flame, smoke, and toxicity. ULTEM™ 9085's superior performance makes it a viable replacement for metal components in maritime applications, reducing weight and improving corrosion resistance.

Salt Mist (Test No. 12): Pass

Cold (Test No. 11): Pass

Flame Retardancy (Test No. 21): Pass

HDT @ 0.45 MPa: 176.9°C

HDT @ 1.82 MPa: 172.9°C

The F900 FDM printer's massive build chamber compliments the material qualities of the ULTEM™ AM9085 from Stratasys®, enabling the manufacture of massive nautical components or many parts in a single print run. The printer's ability to support many materials and is consistent and reliable during operation makes it critical in maritime applications among many other things where component failure can have serious consequences.

F900™

Have your components 3D printed now! Do you have any questions? Contact our experts!

Antero 800NA from Stratasys® - Printed on the Stratasys® F900

Antero 800NA is a PEKK-based (polyetherketoneketone) FDM thermoplastic with superior chemical resistance, ultra-low outgassing, and excellent heat resistance, making it ideal for demanding marine applications.

Its excellent strength and endurance make it perfect for components that will be exposed to harsh maritime conditions, such as fuels, oils, and hydraulic fluids encountered in marine environments. The material's low outgassing properties are especially useful in enclosed places like ships and submarines, where air quality is critical.

Salt Mist (Test No. 12): Pass

Cold (Test No. 11): Pass

Flame Retardancy (Test No. 21): Pass

The F900 FDM printer's massive build chamber compliments the material qualities of the Antero 800NA from Stratasys®, enabling the manufacture of massive nautical components or many parts in a single print run. Using this combination avoids the waste and design limitations associated with subtractive manufacturing of high-cost bulk PEKK material, making it a cost-effective solution for custom or low-volume maritime parts.

F900™