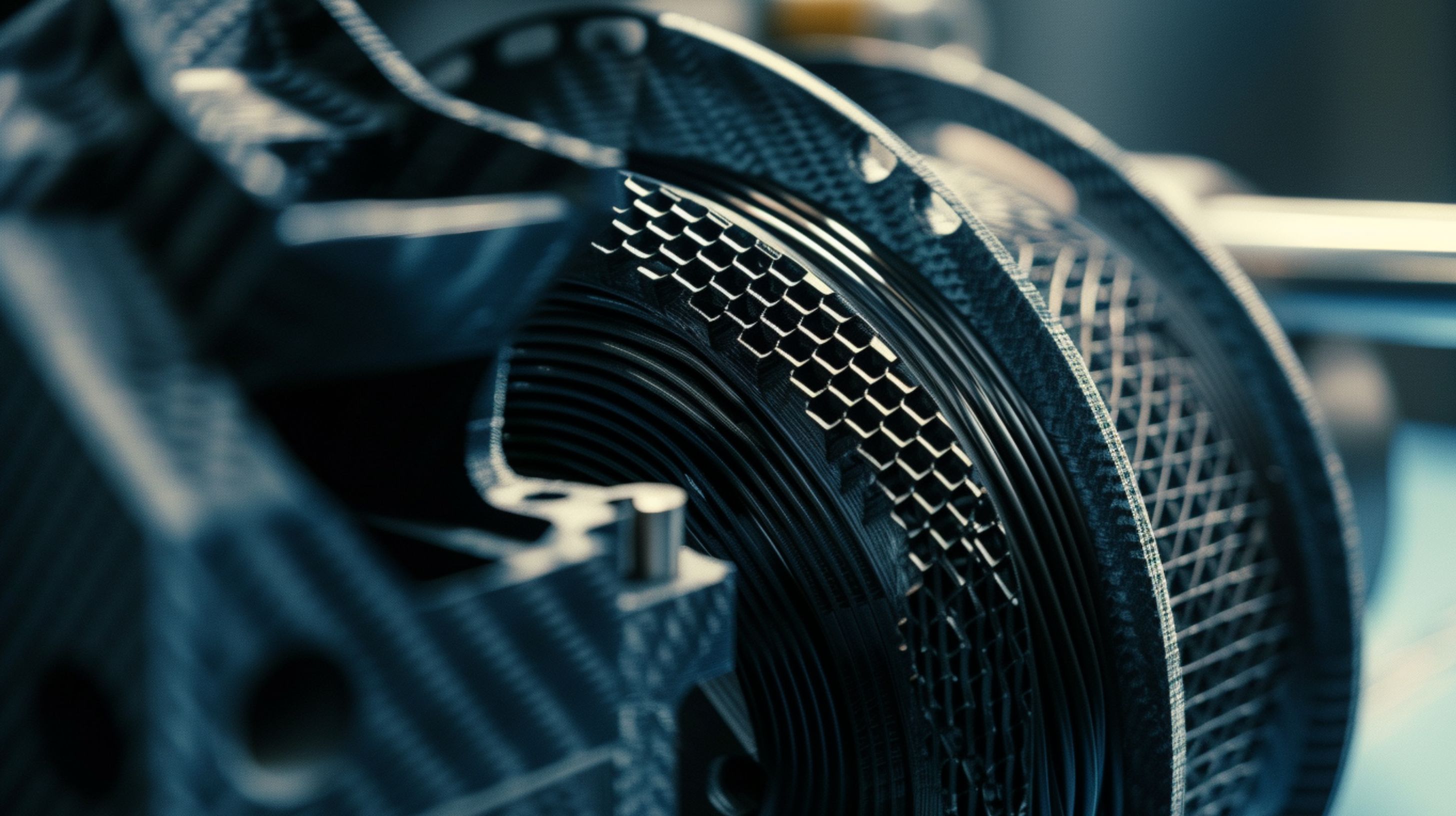

What is carbon fiber?

In 3D printing, the term "carbon fiber" refers to a composite material in which carbon fibers are enclosed in a polymer matrix and thus reinforced. In 3D printing, the term carbon fiber does not have a standardized formula. Instead, it refers to a type of filament or material used in additive manufacturing to make things that benefit from the strength, stiffness and light weight of carbon fibers in a polymer matrix. This composite material is commonly used to make high-performance and durable components in a variety of industries, including aerospace, automotive and industrial manufacturing.

What are the benefits of 3D printing carbon fiber parts?

Exceptional Strength and Lightweight Properties

One of the key advantages of 3D printing with carbon fiber composites is the high strength-to-weight ratio that carbon fibers provide. Carbon fibers' intrinsic strength, paired with their lightweight nature, leads in parts that maintain excellent structural integrity while being substantially lighter than traditional materials. This is especially useful in industries like aircraft and automotive, where reducing weight while maintaining strength is crucial for performance and fuel efficiency.

Design Flexibility and Complex Geometry

3D printing with carbon fiber provides exceptional design versatility, allowing for the production of complicated and sophisticated shapes that would be difficult or impossible to manufacture using traditional technologies. The additive nature of 3D printing enables engineers and designers to optimize structures for strength and functionality, resulting in novel designs. This flexibility is especially useful in businesses that require bespoke and highly specialized components.

Material Efficiency and Reduced Waste

Carbon fiber 3D printing produces less material waste than traditional manufacturing methods. The additive manufacturing process creates parts layer by layer, using material only where necessary. This efficiency in material consumption not only saves money, but it also coincides with sustainability goals by minimizing overall waste. The combination of strength and material efficiency makes 3D printing with carbon fiber an appealing alternative for generating high-performance components while conserving resources.

What are the applications of 3D printing carbon fiber components?

Aerospace - Structural Components and Unmanned Aerial Vehicles

Carbon fiber 3D printing is commonly used in aircrafts to produce lightweight structural components such as brackets, panels, and interior components. The combination of strength and low weight improves fuel efficiency and overall performance in airplanes and spacecraft.

The lightweight yet robust characteristics of carbon fiber-reinforced 3D printed parts makes them ideal for producing components for unmanned aerial vehicles (UAVs). This includes frames, wings, and other structural parts that require a high level of strength and rigidity.

Automotive - Functional Protoypes and Custom Automotive Parts

Carbon fiber 3D printing is utilized in the automobile sector to create working prototypes of car components. This allows for faster iterations in the design process and helps test the performance of things like engine components and interior aspects.

The ability to 3D print with carbon fiber enables the customisation of automotive elements such as lightweight body panels, spoilers, and interior components. This increases fuel efficiency and improves the overall appearance of high-performance automobiles.

Industrial Manufacturing - Tools and Fixtures and End-Use Parts for Machinery

Carbon fiber 3D printing is used in industrial settings to create long-lasting and lightweight equipment and fixtures. This comprises jigs, molds, and assembly aids that take use of carbon fiber-reinforced materials' high strength-to-weight ratio.

Carbon fiber 3D printing is rapidly being used to create end-use parts for industrial machinery. Carbon fiber's structural benefits enable the manufacture of components that require both strength and precision, such as gears and brackets.

What materials do we recommend for carbon fiber 3D printing?

PA11 CF from Nexa3D® - Printed on the Nexa3D® QLS 260

PA11 CF (Carbon Fiber) from Nexa3D® is a sustainable alternative to PA12 that is a material made from a biological component; castor oil that has outstanding robustness, ductility, and impact strength.

This is an excellent material for SLS and is especially well-suited for the production of long-lasting. This material has a high elongation before breaking-elastic, is very impact resistant, has good formability and pliability, and can be utilised for skin contact applications.

With an unrivalled 21-hour cycle time, the Nexa3D® QLS 260 uses a single 60 Watt CO2 laser that can manufacture PA11 CF production components and prototypes with high mechanical and thermal properties.

QLS 260

Have your components 3D printed now! Do you have any questions? Contact our experts!

FDM Nylon 12CF (Carbon Fiber) from Stratasys® - Printed on the Stratasys® Fortus® 450mc

FDM Nylon 12 Carbon Fiber (Nylon 12CF) is a combination of Nylon 12 and chopped carbon fiber that achieves the highest flexural strength and stiffness-to-weight ratio of any FDM material. Nylon 12CF also offers a cleaner carbon fiber addition method than SLA while maintaining equal strength attributes.

In some applications, the strength and stiffness are sufficient to replace metal. Replace heavy metal tools with lighter, more ergonomic carbon fiber FDM tools. Carbon fiber functional prototypes are a faster way to validate designs than expensive and time-consuming metal prototypes.

The Fortus® 450mc provides precise, dependable performance, allowing you to speedup manufacturing and save production costs. Its proven reliability and capability to use the FDM Nylon 12CF (Carbon Fiber) makes it a trusted 3D printing solution for manufacturers in the aerospace, automotive, rail, oil and gas, and commercial products industries.

Fortus® 450mc

Have your components 3D printed now! Do you have any questions? Contact our experts!

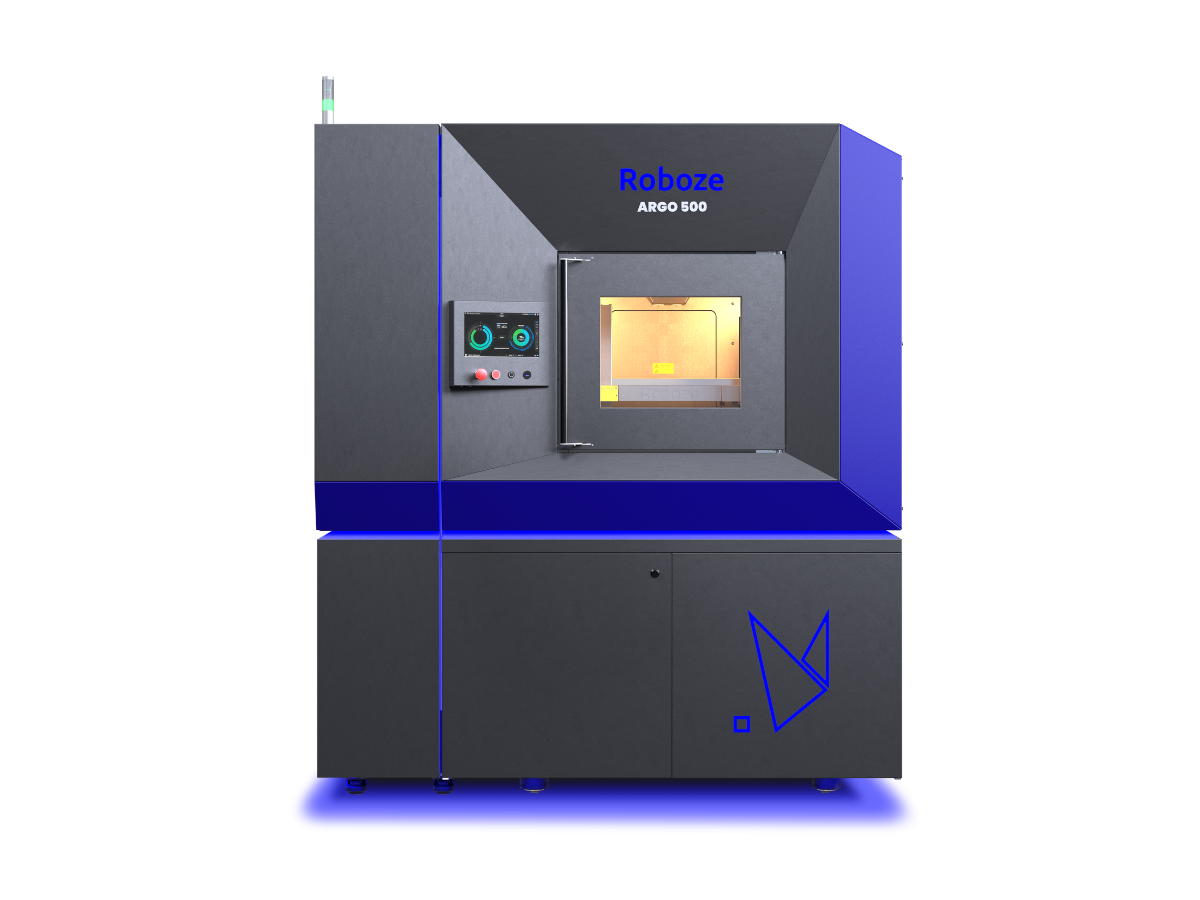

Carbon PA (PRO) from Roboze - Printed on the Roboze ARGO 500

Carbon PA (PRO) is a composite material that incorporates chopped carbon fibers into a polyamide matrix. Reinforcing the semi-crystalline PA 6 plastic with chopped carbon fibers yields a substantially stronger material than standard polyamide.

Roboze's carbon fiber reinforced polyamide provides exceptional mechanical strength, stiffness, and thermal resistance. In addition, the polyamide matrix is robust at low temperatures and easy to process. An ideal alternative for metal substitution applications.

The Roboze ARGO 500 is a high-temperature industrial 3D printer with an extruder capable of reaching 450°C and a build envelope that can heat up to 180°C. The ARGO 500 works with the Carbon PA (PRO) and can produce large-format parts with 10 µm positioning accuracy and consistent reproducibility.

ARGO 500