3D printing, also known as additive manufacturing, has transformed entire industries. The ability to manufacture highly complex components quickly and accurately has become essential for a wide range of industries to capitalize on market trends faster, test new ideas more quickly, and prevent downtime.

However, as important as speed is, the quality of the components is, of course, still the main focus. After all, what good are quickly manufactured components if they show signs of fatigue after just one use?

3D printing can ideally combine speed and quality, but usually only in highly industrialized facilities. However, these facilities come with another disadvantage – relatively high acquisition costs.

This has led to a divide within the industrial sectors that now make extensive use of 3D printing. A gap between large companies and corporations, which can easily afford the high acquisition costs, and SMEs (small and medium-sized enterprises), which, due to a lack of financial resources, often resort to 3D printers for private individuals, which can also offer excellent speeds but do not meet the quality requirements for industrial applications.

Part of our vision is to close this gap with our service. We want to enable SMEs to combine speed and quality through additive manufacturing in order to offer their customer base products and services like a large corporation.

This blog post is about how our service helps SMEs to close the gap with large companies and why a large number of SMEs already rely on us.

Using advanced technology without acquisition costs

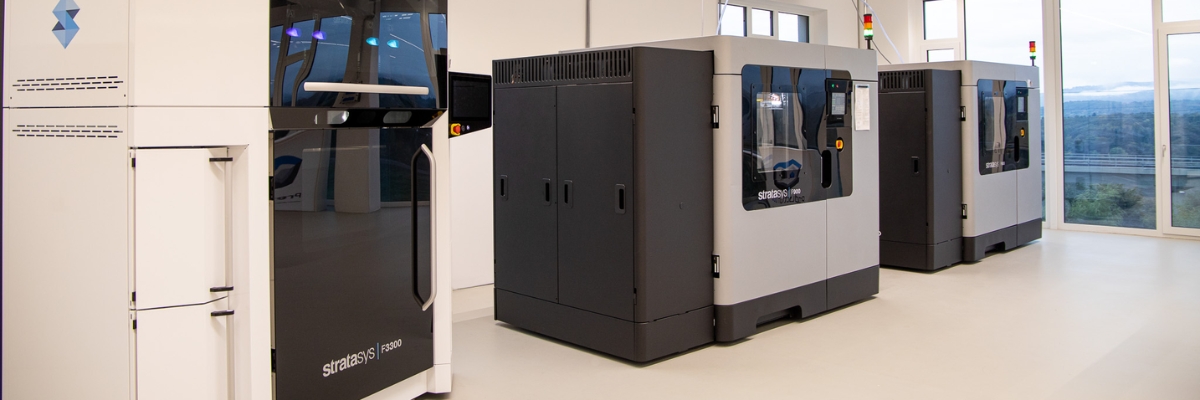

As one of the largest 3D printing service providers in Europe, we can pride ourselves not only on following the latest developments in 3D printing, but also on actively supporting them and always being one of the first service providers to make these developments available to customers.

This gives our partners and customers, whether they are sole traders, medium-sized companies or large corporations, a unique market advantage. By being one of the first providers to take advantage of these new developments, they stand out from other market players and can thus attract new customers.

These developments not only address the printing systems themselves, but also post-processing solutions, material selection, software and much more that we use to not only meet but exceed the requirements of our partners and customers.

By utilizing new technologies, our customers are given a unique selling proposition that allows them, among other things, to produce previously impossible geometries, integrate brand-new material properties into their products, respond more quickly to trends and achieve many other potential benefits.

Reaching niche markets efficiently

SMEs are, of course, not only found in mass markets such as the automotive industry or the consumer goods sector, but are often in niche markets, for example luxury goods, specialized leisure items or hardware for unusual industries.

These niche markets usually require relatively unique products – be it in terms of geometry, material properties or functions. Service providers who work purely with conventional manufacturing methods are less likely to be able to help, since changeover times would be needed to implement the requirements for several specific projects.

However, thanks to our use of additive manufacturing and our large production capacity with over 100 industrial printing systems, we can also implement numerous specific projects – completely without having to apply changeover times.

For our customers, this means significantly shorter waiting times on the one hand, but on the other hand, the costs of the changeover do not have to be passed on to the customer either. In addition, short-term changes can be implemented quickly, which means that rapid market changes are no longer a problem.

Scalability for expansion

Until now, the only way for companies to close the gap between large corporations and SMEs was to grow into a large corporation themselves. Even if our service can close the gap in other ways, the goal of expansion naturally remains for a large number of SMEs – and our service can also provide perfect support for this.

Our expertise and additive manufacturing are not specialized in a particular area, such as small-batch production, but cover all manufacturing strategies – from single pieces to large-scale production of millions of components.

Our range of services can thus grow in symbiosis with SMEs. Perhaps starting with a few individual prototypes, through to the production of end-use parts in small series, to full series production, we can support companies in delivering their components on time and in the highest quality.

However, this scalability applies not only to company size but also to portfolio size. Thanks to our wide range of different printing technologies, which is constantly growing, we can cover everything from small, delicate components to large-format components and everything in between, which means that we can also help SMEs to expand their portfolio more easily and efficiently.

Experimentation without high risk

When it comes to research and development, large companies have a considerable advantage over SMEs. With entire business units often dedicated solely to R&D, as well as far greater financial resources to drive both research and development and cushion potential failures, large companies can take far more risks and thus drive progress faster.

We enable SMEs to replicate the productivity of the R&D process of large companies without taking the same risks. There is no need to incur the costs of new equipment, hire new employees or learn new workflows – simply create a digital model and we'll take care of the rest.

Our team and their experience are invaluable, especially for new projects. With several experts focusing specifically on R&D, we can provide SMEs with important tips and suggestions for improving their development project, which can minimize the need for iteration cycles.

And last but not least, the outstanding speed of our service not only helps to complete projects quickly, but also to implement changes quickly and efficiently. This way, the already reduced iteration cycles can be further accelerated to advance research and create new market advantages for our customers.

Faster market launch of new products

The market launch is one of the most essential steps for every product. A small mistake or just a few days delay can be enough to undo all the work and expense involved in developing a new product.

This step is also one of the most laborious processes in the entire product life cycle. All resources from every department – from marketing to distribution to manufacturing – must be combined to ensure the perfect launch.

By using our service, product development can be carried out much faster and market launch can be achieved with much less effort. With the capabilities of 3D printing and our team, we can produce functional and design prototypes very quickly, which can then be immediately subjected to the necessary testing and, with our help, quickly modified.

When it comes to launching a product, SMEs with limited resources can devote themselves entirely to activities other than production, because we take care of these. In this way, our service can ensure that the market launch is faster and more orderly.

Managing production peaks

The market is not always predictable. A multitude of factors, all intertwined and influencing each other, determine the basic principle of supply and demand, and some of these factors, such as geopolitical events, can hit companies unexpectedly.

However, such unexpected events are not always negative. Changed market situations can also quickly lead to a large number of new buyers or orders. However, this undoubtedly positive reaction is not completely free of difficulties, especially for SMEs, since production capacities can potentially be quickly utilized and expanding these capacities cannot be done overnight.

We offer SMEs the opportunity to bridge this period in an ideal way by taking over parts of their production without any problems. Thanks to our large team and our high number of printing presses, we can make such a capacity expansion possible very quickly, so that companies do not have to turn down any orders.

Conclusion

SMEs are one of the most important pillars of the German economy. According to the Federal Statistical Office, they represent 99.3% of companies in Germany and employ approximately 38.7 million people in Germany – 55% of the working population.

Our service enables this backbone of Germany to massively expand its opportunities without having to take major financial risks – especially since we are currently offering a 25% discount on first orders until 31/03/2025. This way, SMEs can test our expertise directly against their requirements to see our quality for themselves.

Here you will find an ideal overview of the various areas of application that we cover for SMEs. Otherwise, all that remains to be said is – thank you for your attention and see you in the next blog post!