3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Based on the award-winning Raise3D E2 3D printer, the Raise3D E2CF is designed for printing fiber-reinforced materials and optimized for carbon fiber.

The Raise3D E2CF meets the requirements of various industries, such as automotive, aerospace and healthcare, which need to produce components with a high strength-to-weight ratio and consistent high quality.

The Raise3D E2CF is specifically designed for carbon fiber reinforced materials and can print brake-away support structures. The two dry boxes for material storage and the improved extruder enable a smooth printing process for composites.

The Raise3D E2CF printers can be easily connected to Raise3D's 3D printing software ecosystem, which includes ideaMaker slicing software and RaiseCloud management software.

The Raise3D E2CF's 3D printing nozzles are specially made of hardened metal to handle abrasive materials with ease.

The gears of the Raise3D E2CF are made of high-strength steel and have been heat-treated for better wear resistance. With a custom tooth profile, the filament is held firmly in place to ensure it does not slip during extrusion. The power of the device has been increased to ensure the stability of the print.

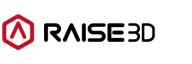

The printheads are easily removable so that one printhead can be easily exchanged for another. The exchange may be necessary if, for example, a different printhead with a different nozzle diameter is to be used.

Replacement Easy Swap printheads can be prepared with hardened nozzles in various sizes, such as 0.4, 0.6 and 0.8 nozzles.

The Raise3D E2CF is an IDEX 3D printer. IDEX stands for Independent Dual Extruders, which means that the extruders can operate independently along the same axis during printing to perform advanced functions.

Mirror mode prints a model and an inverse of the same model at the same time. This saves the creation of a second design file for the inverse model and time when printing separately.

Duplicate mode is a synchronized print where both extruders print the same model at the same time.

The Raise3D E2CF has the same build volume as the E2:

Single Extruder Print: 330 × 240 × 240 mm (13 × 9.4 × 9.4 in.)

Dual extruder printing: 295 × 240 × 240 mm (11.6 × 9.4 × 9.4 in.)

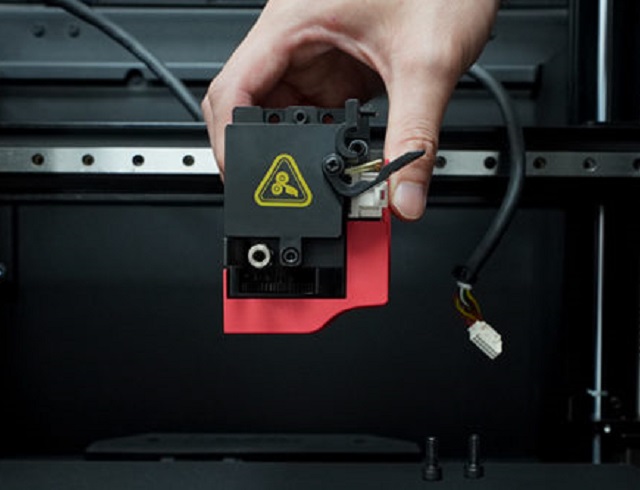

The Raise3D E2CF has an automatic leveling function. Automatic print bed leveling keeps the distance between the print nozzles and the print bed constant to create a uniform print surface. This improves the adhesion of the print bed and allows the extruder to adapt to even the smallest changes in surface contour for better print quality.

The built-in hanging trays are used to place the filament and allow the material to feed more evenly. When the dry box is closed, the material can be effectively protected from dust and moisture for up to 30 days.

Raise3D Industrial PA12 CF Support Filament is a breakaway support material specifically designed for carbon fiber-reinforced composite filaments. During the 3D printing process, it forms a stable support structure that ensures good adhesion to the printed surfaces and counteracts any tendency to warp. This significantly improves the surface quality of the overhangs and recesses of the printed objects. After printing, the carrier structure can be easily removed or broken off from the printed parts. This substrate has broad compatibility with many high-performance carbon fiber-reinforced composite filaments and is more cost-effective compared to the water-soluble substrate.

The Raise3D E2CF desktop 3D printer features a special drive system that enables smooth gliding during printing. To ensure the highest level of accuracy for 3D printing processes, this motion system works with extremely precise positioning.

The Raise3D E2CF features slicing profiles that have been extensively tested and verified by Raise3D engineers in ideaMaker. You do not need to adjust the parameters before printing. Enjoy easy and high-quality printing.

Like other Raise3D products, the E2CF can realize series production and intelligent management with ideaMaker as the core software solution.

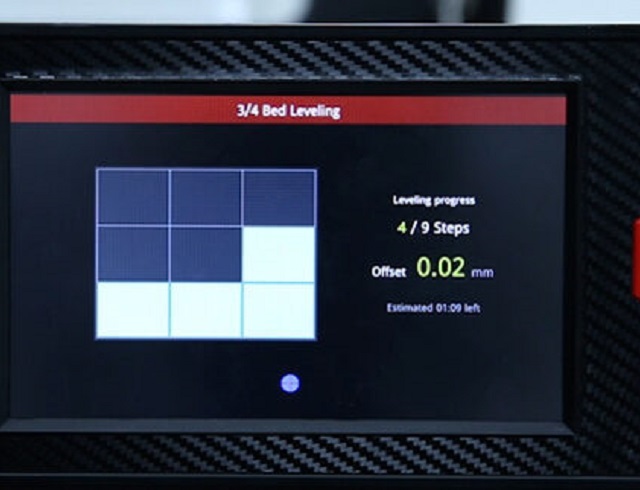

The Raise3D E2CF desktop 3D printer has a HEPA air filter that cleans the air of all particles (including nanoparticles) released during the 3D printing process. The HEPA air filter works effectively in classrooms, offices, and large and small workshops.

The 7-inch touchscreens allow users to interact directly with the printer. It provides visual support and model selection to simplify control and monitoring of the printing process.

The Raise3D E2CF has a filament run-out sensor that warns when the filament is almost empty and saves the print. It also has a second-generation power failure feature that allows printing to resume from where it was previously saved in the event of a power failure.

The complete 3D printing process of each print job is monitored by the Raise3D E2CF with a camera. By connecting to RaiseCloud, the user is enabled to monitor each print process remotely and on mobile.

Sometimes parts with sufficient strength can be manufactured to replace equivalent parts made of metal.

Fiber-reinforced 3D printing materials enable the production of functional, dynamic parts that can withstand the demands of continuous use.

Raise3D enables users to quickly produce specific, customized solutions for their manufacturing. It eliminates the need for molds, castings, or subcontractors and provides benefits that would be impossible to achieve with traditional manufacturing methods.

Parts for immediate use can be produced quickly and meet very specific requirements for all conceivable applications.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy