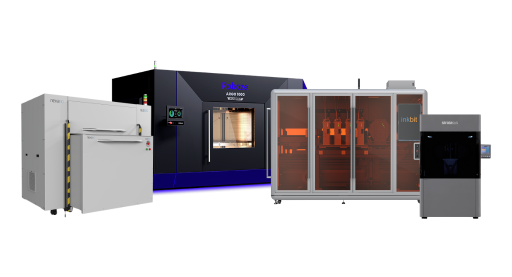

3D printers

High quality 3D printers

High-quality 3D printing solutions for demanding projects

Order Parts now!

Series production with high quality and quantity

Manufacture high quality metal components

High resolution components in all quantities

High quality components without support structures

Wide range of known materials

Ideal for a variety of indications

For the completion of your components

Production cells enable series production of high volumes

Fast data processing and successful quality management

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

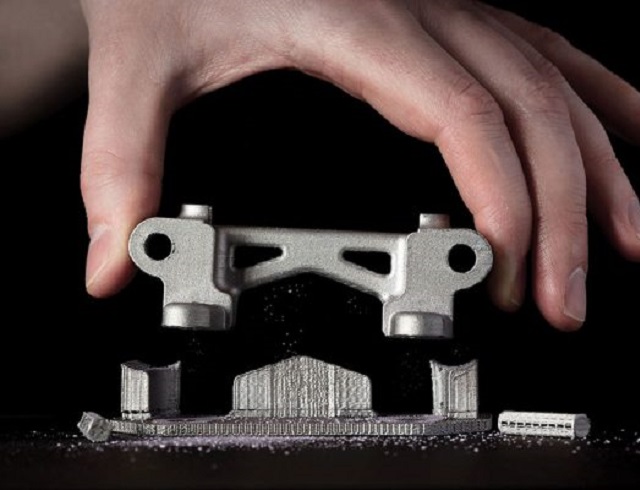

During model preparation, Fabricate detects potential problems such as the removal of hard-to-reach supports. If support structures are enclosed within the part or are difficult to access, they cannot be removed in post. In these cases, the software creates a "seam" through the support structure, dividing it into easily removable sections.

The software analyzes the geometry and creates support structures that prevent deformation and allow for uniform shrinkage. A ceramic layer is then generated and printed between the part and its support. This layer disintegrates in the oven, allowing separable supports that can be easily removed by hand.

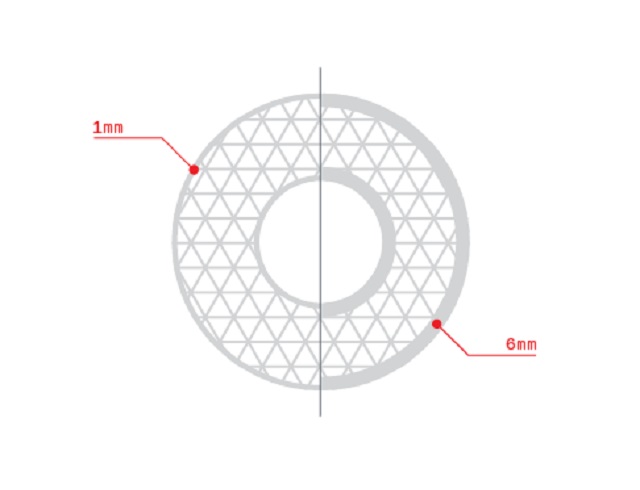

Advanced settings allow users to adjust wall thickness between 1 mm and 6 mm. Thicker walls provide additional material for post-processing and contribute to improved overall model strength, while thinner walls reduce manufacturing time by allowing for a faster sintering cycle.

Models are automatically aligned to improve process success and enhance ease of use. The best possible alignment is determined by analyzing the part at each stage of production (printing and sintering) to achieve better surface quality or optimize printing time.

Based on the material, part geometry and user-defined settings, the software generates complete manufacturing profiles for printing and sintering. No parts need to be weighed after printing, no data needs to be entered into the software, and no equipment instructions need to be entered manually.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy