3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

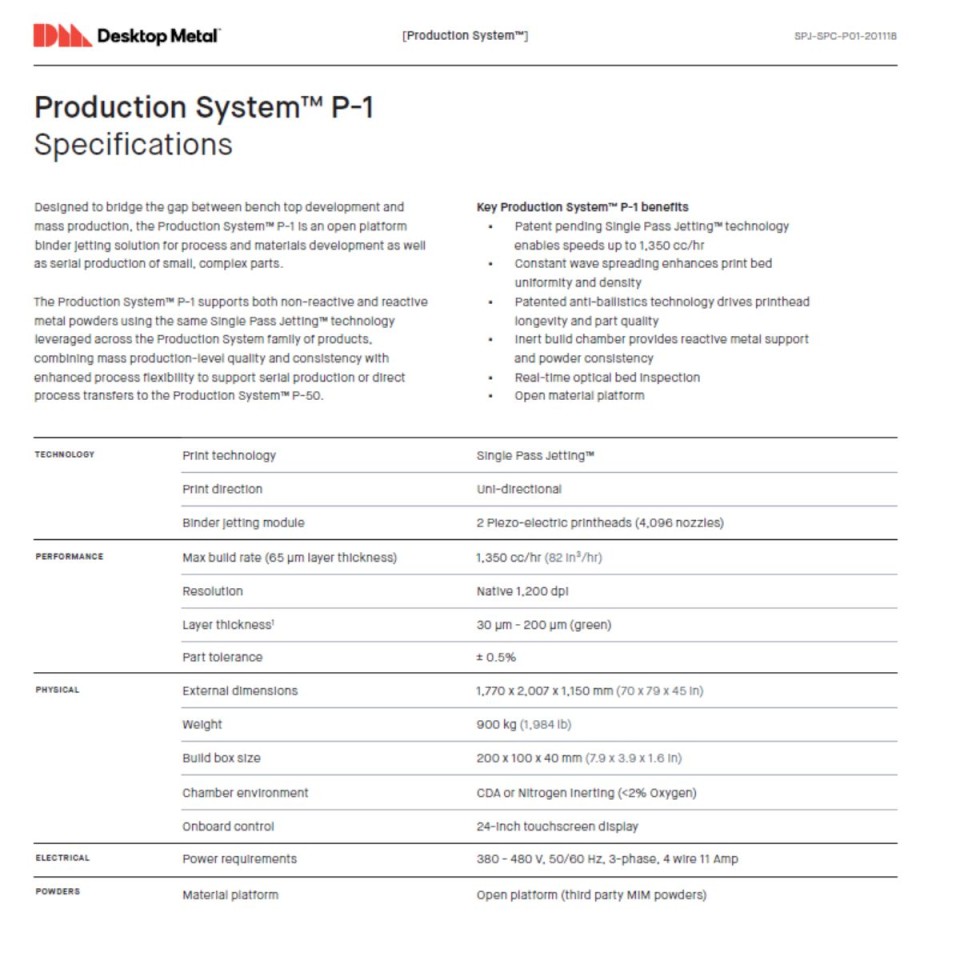

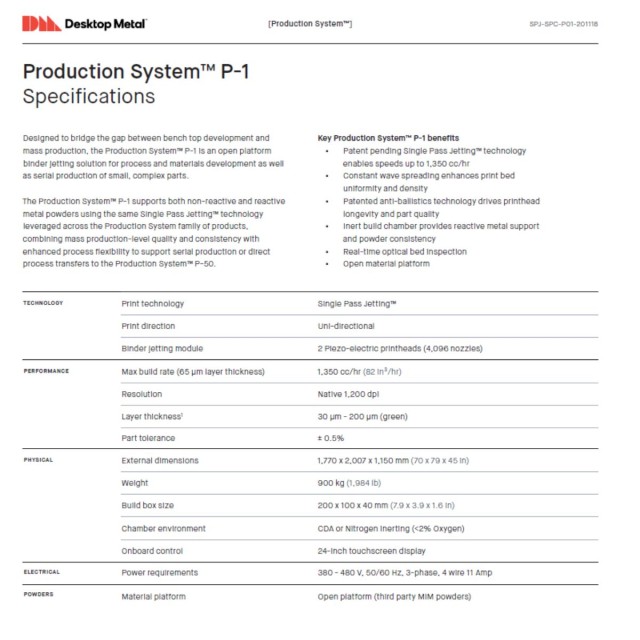

The open platform binder jetting system is ideal for the mass production of small, complicated parts as well as process and material development.

Desktop Metal® also relies here on Single Pass Jetting ™ technology, which is also used on the P 50. The powder is applied with a layer height of 50 µm, and the resolution here is also 1200 x 1200 dpi.

Of course, both reactive and non-reactive metal powders can be processed here as well.

The P1 increases your process flexibility and is the link in mass production to the P 50, supporting process transfer and closing the gap from development to series production.

The system uses 2 piezoelectric printheads (4,096 nozzles) and a unidirectional binder jetting module that enables print speeds of up to 1,350 cc/h.

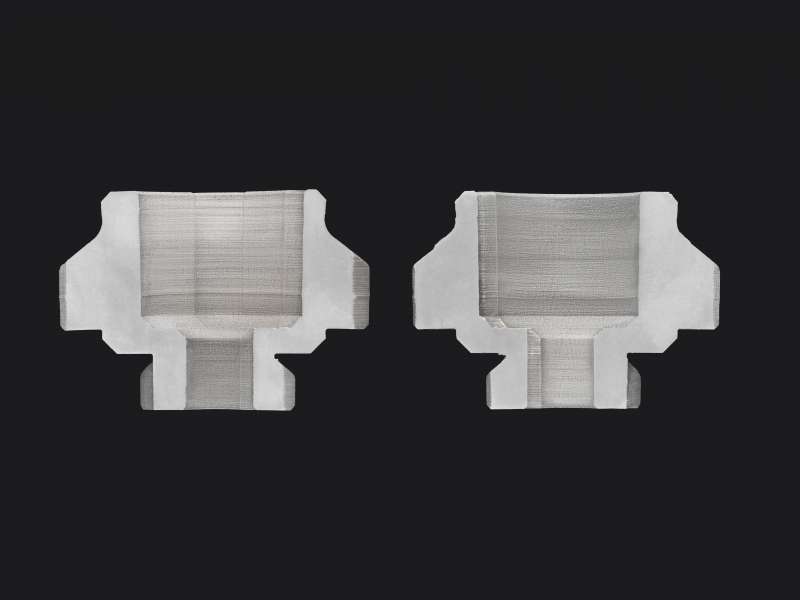

Using unique "Constant Wave Spreading" technology, metal powder is sprayed over the entire printing process, so that a constant powder wave in front of the compaction roller ensures uniform density distribution in the powder bed. Due to the greater compression of the individual layers, better surface values and higher densities are achieved for the components.

Without solvent debinding, non-solid printed parts can be produced with densities of up to 99% or more. The system is suitable for the production of components for demanding casting/MIM applications, as comparable strengths are achieved.

The patented anti-ballistics technology was developed to minimize disturbances in the powder bed. This significantly reduces variability in the 3D printing process and extends the life of the print beam. This ensures excellent part quality and reliable prints.

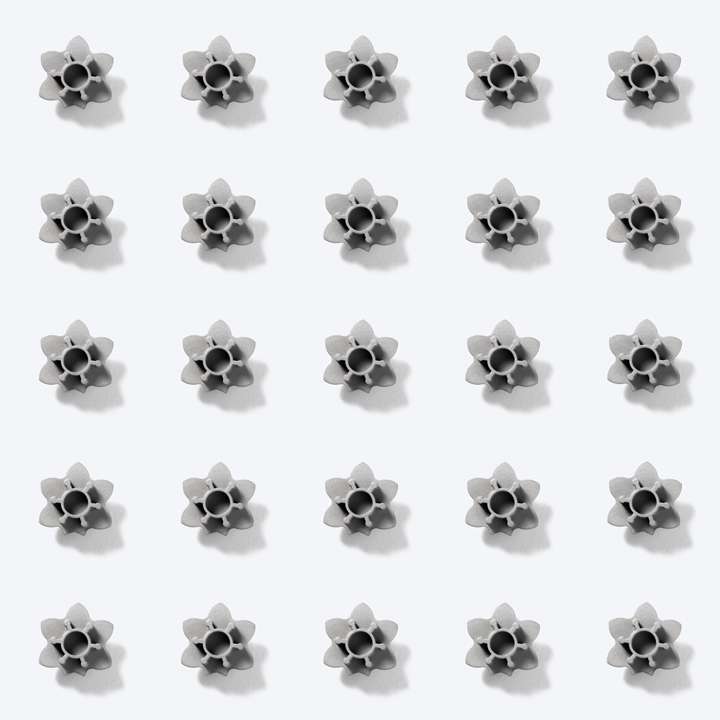

The Production System's tool-less binder jetting 3D printing process supports parts with loose powder and eliminates the need to weld to a build plate. This allows customers to effectively fill the build volume with densely nested parts for high throughput.

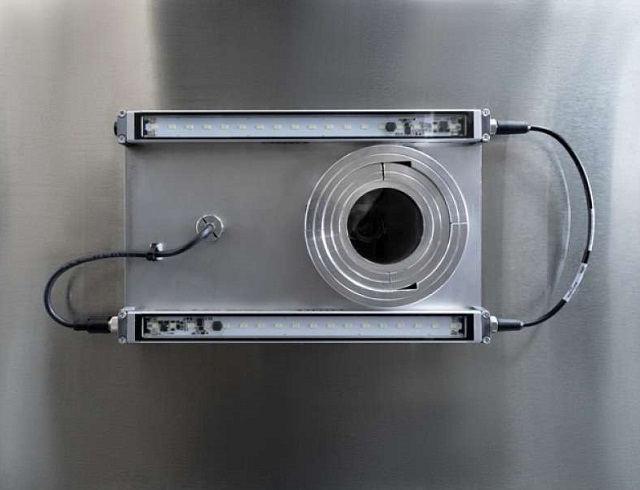

To enable the use of additive manufacturing in production environments, an integrated camera monitors the process by taking pictures from different angles. This allows printing errors to be detected at an early stage and nozzle performance to be checked.

To keep component manufacturing costs as low as possible, the P1- Production System™ features an open material platform. This allows the customer to use the same metal powders used in the MIM sector or to resort to customer-specific alloys.

Bidirectional single-pass jetting, combines all 5 individual steps of the entire printing process (powder application, spreading, compaction, ballistic suppression and binder ejection ) and is performed over the complete build area for each pass.

After the print job is finished, the kit is removed and placed in the powder station. Here, the loose powder is removed and recovered via a built-in powder recycling system.

The cleaned parts are briefly baked together in an industrial furnace below melting temperature, where the binder is burned and the metal particles fuse together.

Call or email us and we will be happy to help you.

Shorten product development times, through rapid 3D printing of functional prototypes

Increased flexibility, through tool-free production of small and large batches

Shorten lead times for end-use parts by simplifying manufacturing processes

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy