3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Reliable, productive and efficient, the Stratasys® Neo®450s is designed and engineered for industrial manufacturing.

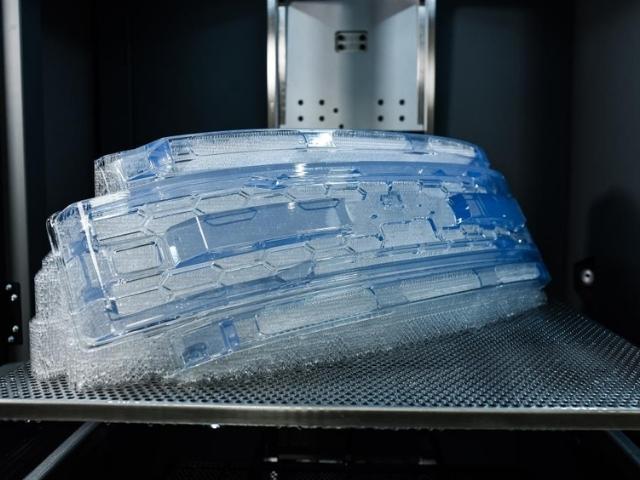

The Stratasys® Neo®450s with a build volume of 450 x 450 x 400 mm is up to 40% faster than Stratasys® Neo®450e and offers standard and high-definition build modes. The SLA printer is ideal for users who need high-definition parts for their applications. The Stratasys® Neo®450s variable laser beam technology allows you to quickly produce SD parts or produce HD parts with fine resolution and intricate, small details. A VAT swap for a material change is also possible!

Key Points:

Laser: 2 watts; 355 Nm, solid state.

Beam focus: Dynamic & variable

Beam size: 80 to 750 μm

Layer resolution: 50 to 200 μm

Build volume: 450 × 450 × 400 mm

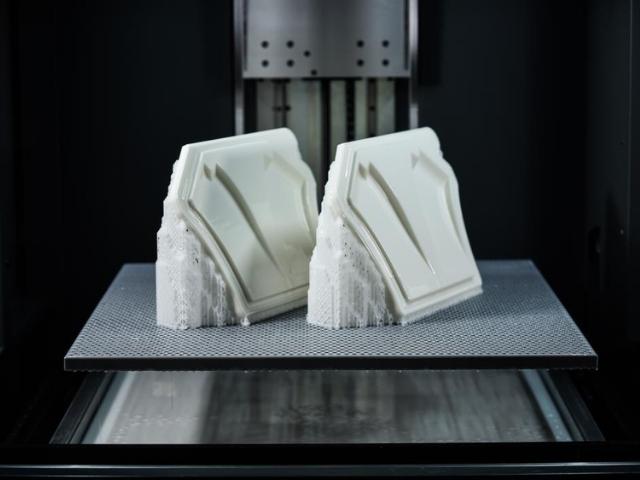

The compact Stratasys® Neo®450s, based on the proven Stratasys® Neo®800, features a 450 x 450 x 400 mm build platform and produces master models, tooling, and prototypes with remarkable surface quality, accuracy, and detail.

The Stratasys® Neo®450s is a cost-effective industrial SLA printer that produces small to medium-size parts with consistent accuracy and repeatability. It is equipped with a 2-watt laser that has a beam size of 80 to 750 µm and features dynamic and variable focus.

The Stratasys® Neo®450s offers all the benefits of the Stratasys®Neo®450e SLA printer, plus more power and greater versatility. Stratasys® Neo®450s is up to 40% faster, has standard and high-definition build modes, and produces the highest quality parts.

The beam delivery system of the Stratasys® Neo®450s, provides remarkable repeatability of precision from layer to layer by using the latest laser and scanner technology. Printed parts have excellent sidewall and high detail resolution and are dimensionally accurate.

The high-power laser of the Stratasys® Neo®450s processes all 355 Nm SLA resins currently available on the market with optimal productivity. An open material system means that users are not bound by the usual parameters and manufacturer materials.

Stratasys® Neo®450S is carefully engineered, developed with state-of-the-art technology, and equipped with proven components and aesthetic finishes.

Use the built-in camera, emailed progress reports, and status updates to stay informed. Customer recommendations and suggestions are the basis for Neo Series software updates.

Prepare for printing with intuitive Titanium software, which optimizes print quality and captures print data for better traceability to increase work efficiency.

Dynamic laser focusing and SD and HD build modes enable the production of highly accurate and detailed parts with intricate, small and large designs.

Washing print models ensures that uncured resin is removed from the surface of the components. The washing process takes only a few minutes.

Printed parts must undergo a final curing process. Stratasys® UV800 is designed to meet this requirement with high-intensity UV lamps and a rotary table.

High-volume, high-throughput printing is used in demanding areas such as service bureaus or internal centralized manufacturing departments.

Print extensive idea and communication models to assess the accuracy of functional fit and form.

Creating production jigs and molds for small batch injection molds.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy