3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

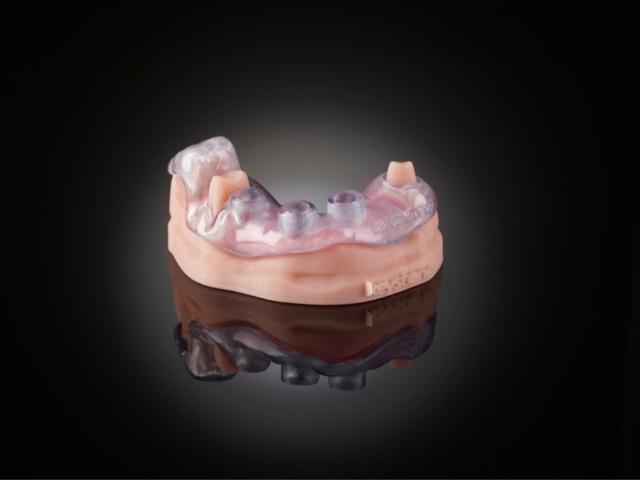

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Ultra-fast, accurate, and reliable 3D printer for dental applications. Models, drill guides, splints, impression trays and occlusal splints can be printed very quickly with the Nexa3D® NXD 200.

The Nexa3D® NXD 200Pro is the ideal 3D printer for high-throughput dental applications. 275 x 155 x 200 mm, a record-breaking build volume of 8.5 l, and patented LSPc® technology. This comprehensive 3D printer is perfect for printing grinding trays, custom impression trays, splints, dental models, and more. The intuitive user interface and ease of use match the excellent speed and throughput, making the Nexa3D® NXD 200Pro perfect for dental labs.

Key features:

- Higher throughput for better profitability

- Print up to 20 flat models in 30 minutes

- FDA & MPG approved materials

- Uniformity and accuracy across the build volume

- 4K resolution for excellent detail and an impressive surface finish

The NXD 200Pro features the following improvements over the Nexa3D® NXD200:

1. higher throughput - The Pro series utilizes the latest generation Nexa3D® light engine in combination with the patented Everlast diaphragm technology, the pull-off forces are minimized, thus a higher pull-off speed can be used.

2. expanded resin portfolio

3. improved process reliability - an improved auto-homing algorithm optimizes the adhesion of the first baselayer to the build platform

4. two build plate designs (solid and slotted) - the solid build plate is designed to increase the effectiveness of post-processing and is compatible with low-viscosity resins. For higher viscosity resins, there is still an optimized version of the hardened slotted design.

5. new setting profile manager in NexaX software - users now have the ability to create open material profiles for their own or third-party resins.

6. Armored LCD Mask - resistant to wear and tear during the printing process.

[NOTE: All Nexa3D® NXD 200 printer owners, can purchase an upgrade kit to the Pro version].

Dental manufacturing solutions you can rely on are brought directly to your lab with ultra-fast 3D printing using certified materials. Meet the demand for increasing volumes with a single, faster 3D printer that has a much larger build volume. It's also easy to use and reduces the cost per part.

Benefit from the homogeneity, reproducibility, and precision of the Nexa3D® NXD 200Pro build platform of 90-95% at 100 µm. In-house production of patient-specific 3D-printed dental models, surgical guides, splints, trays, and nightguards is fast, reliable, and accurate.

Everlast-2 membrane provides superior print quality, fidelity, and speed, as well as outstanding durability. Everlast-2 membrane can withstand up to 25 times more printed layers (50,000+) than comparable films used.

The Nexa3D® NXD 200Pro 3D printer, designed specifically for dental applications, offers high-performance dental resins from Keystone. This covers important patient-specific indications such as 3D-printed dental models, surgical guides, splints, customized impression trays, and grinding splints.

The Nexa3D® NXD 200Pro sets new standards for dental materials productivity:

KeyModel Ultra™ for dental and orthodontic models- A complete build platform can be printed in less than 30 minutes.

KeySplint Soft™ and KeySplint Hard™ for bite splints, knee splints, occlusal splints, etc.:

- A complete build platform with up to 30 - 40 splints can be printed in approximately 1 hour and 45 minutes

Key Guide® for drill guides

- A complete build platform with up to 30 - 60 drill guides can be printed in approx. 1 hour and 15 minutes.

Using the Nexa3D® NXD 200Pro and its associated workflow, the materials and processes have been verified by Keystone Industries as Keystone compliant, ensuring the safe manufacture of medical devices.

Analyze parts for the ideal printing process and use the material selector and automated support algorithm to achieve the highest material properties and reduce costs.

With LSPc® (Lubricant Sublayer Photo-Curing) technology, you can print your parts with lightning speed and process reliability with the Nexa3D® NXE 200Pro.

To wash off the excess resin, the printed parts are cleaned with either the Nexa3D® xWash or another wash station.

In order to achieve the specified material properties, the printed parts must be post-cured using either the Nexa3D® xCure or another post-curing device.

Call or email us and we will be happy to help you.

Together with the KeyModel Ultra™, you can 3D print dental and orthodontic models that are ideal for dental working models or for thermoforming aligners.

In combination with KeySplint Soft™, you can print bite splints, knee splints, etc. that have robust and flexible material properties without becoming brittle. This gives the printed splints made from KeySplint Soft™ the strength needed to protect teeth, such as during nighttime teeth grinding. The additional flexibility ensures more comfortable wearing.

KeyTray™ allows you to quickly and accurately digitally fabricate custom impression trays that are strong and durable to withstand the forces involved in taking a patient's impression and removing the tray from the oral cavity. It is compatible with all types of impression materials.

KeyGuide® is a sterilizable material suitable for the fabrication of surgical guides. This allows dentists to place implants precisely and in the correct position.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy