3D printers

High quality 3D printers

Simply fill out the form behind the button and receive a free sample of a technology of your choice!

3D printing with resin is the oldest type of 3D printing and includes earlier technologies such as Stereolithography (SLA) and Digital Light Processing (DLP) as well as new processes such as Lubricant Sublayer Photo-curing (LSPc®), Vision-Controlled etting (VCJ) and PolyJet™.

In this type of 3D printing, the resin, which is either in a tank into which the build plate is submerged or is sprayed onto the build plate from print heads, is selectively cured layer by layer using UV light. This UV light can be directed onto the build plate by a laser (SLA), a screen (DLP & LSPc®) or UV lamps (VCJ & PolyJet™).

In particular, 3D printing with resin impresses with its exceptional surface quality, high component complexity, zero print distortion, outstanding level of detail and the ability to achieve very high transparency levels.

In SLA printing, a UV laser beam is used for curing, which moves from point to point, thus tracing the geometry of the digital model.

SLA scores with an extraordinary precision of ± 0.1 mm and is the best solution for maximum transparency. However, SLA printing is somewhat slower than other resin technologies because the laser has to cure the points on the construction plate individually.

In the DLP process, a stationary projector is used to project UV light onto the build plate, curing the entire layer at once.

DLP 3D printers deliver higher speeds than SLA printers and the intensity of the light source can be easily adjusted. However, DLP printers are at a disadvantage in terms of print resolution and build volumes because the projector is limited in the number of pixels it can project.

LSPc® technology, which is based on MSLA (masked stereolithography) technology, uses a combination of a high-resolution LCD screen and an LED array to cure the entire resin layer in a single pass.

Printers with this technology impress with exceptionally fast print speeds and razor-sharp 8K resolution, but, as with DLP, they are limited in build volume.

In contrast to the previous methods, PolyJet™ does not use a resin tank. Instead, it injects the resin onto the construction platform using print heads, where it is cured by surrounding UV lamps.

PolyJet™ printers can be used to print components with multiple materials and colors simultaneously, as well as with very smooth surfaces. However, to ensure component stability, PolyJet™ printers are limited in height.

VCJ uses a movable carriage with print heads and UV lamps to apply and cure resin. In addition, a high-resolution camera is mounted on this carriage to create a topographical map of each layer and compare it with the model.

VCJ particularly excels in terms of its dimensional accuracy, component complexity and multi-material capability. Unfortunately, the choice of materials is still very limited.

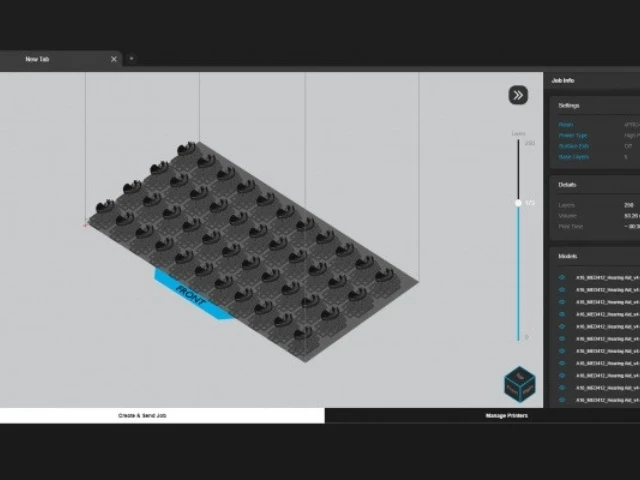

The first step is to prepare the print data using selected CAD or 3D modeling software. The prepared data is then transferred to the 3D printer and processed.

After checking the correct print settings, the printing process begins and the 3D printer can run unattended until completion. For printers with a cartridge system, material refilling is fully automated.

Once the printing process is complete, the component can be removed from the build chamber. Depending on the geometry, the components are now removed from the build platform or remain on the build plate until they have been washed and hardened.

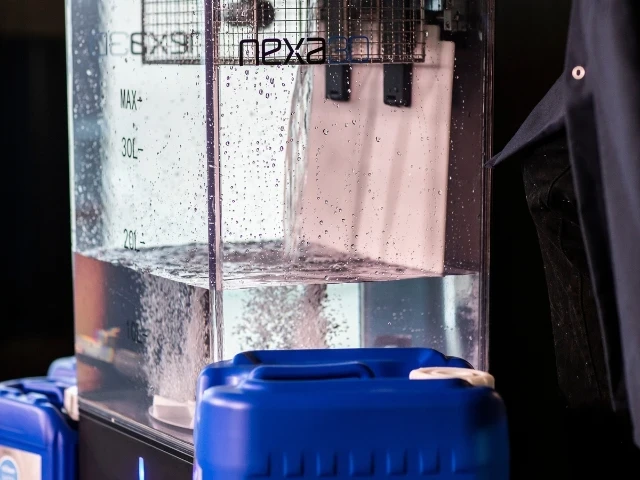

The components are then washed, whereby the excess resin is removed from the surface. Depending on the type of resin, either solvents (e.g. isopropyl alcohol) or simply water are used.

The materials do not reach the maximum degree of polymerization due to the pressure. For this reason, the components are post-cured after cleaning in a UV oven, which guarantees the highest possible strength and stability.

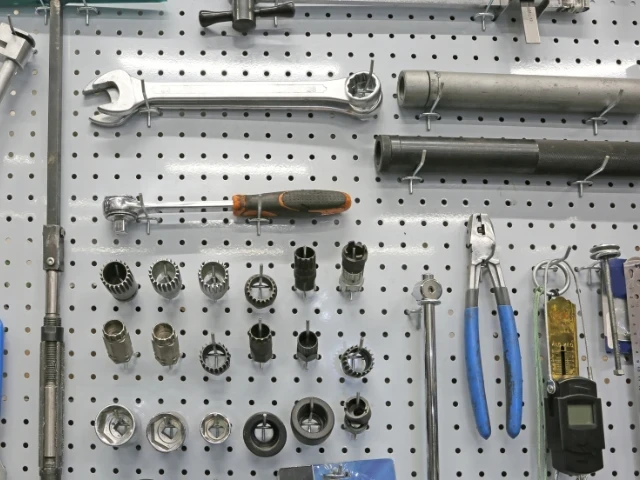

In the final step, the support structures are removed. Here, the component can also be mechanically reworked or painted.

Resin components are very popular in aviation due to their stability, wear resistance and low weight combined with good mechanical properties. Possible components include wind tunnel models, structural components, production aids and engine components.

The lightweight and resilient materials used in resin 3D printing can save large amounts of weight and therefore fuel in the automotive industry. Possible components include interior and exterior trim, performance components, structural components and prototypes.

Thanks to the very high design freedom and outstanding surface quality, resin 3D printing is often used for personalization and spare parts production in the sports and leisure segment. Possible components include sports equipment, protective equipment, boat parts and accessories.

With a large selection of biocompatible materials and a high level of detail, patient-specific and high-quality indications can be produced with resin in dental medicine. Possible components include bridges, crowns, splints of all kinds and dental models.

Thanks to high precision, biocompatible materials and fast production times, 3D printing with resin is playing an increasingly important role in medical technology. Possible components include surgical instruments, medical models, tissue scaffolds and prototypes for medical devices.

3D printing with resin offers the ideal opportunity for rapid tooling thanks to mechanically efficient materials and breathtaking production speed. Possible components include high-performance tools, injection molds, vacuum molds and thermoforming tools.

Our team of experts will be happy to support you in choosing the right 3D printing technology and in selecting the right 3D printing system.

Our application team also advises you on the choice of materials. Among other things, we can provide cost and time calculations as well as sample parts. In our showroom we have the possibility to validate the project together with you!