3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

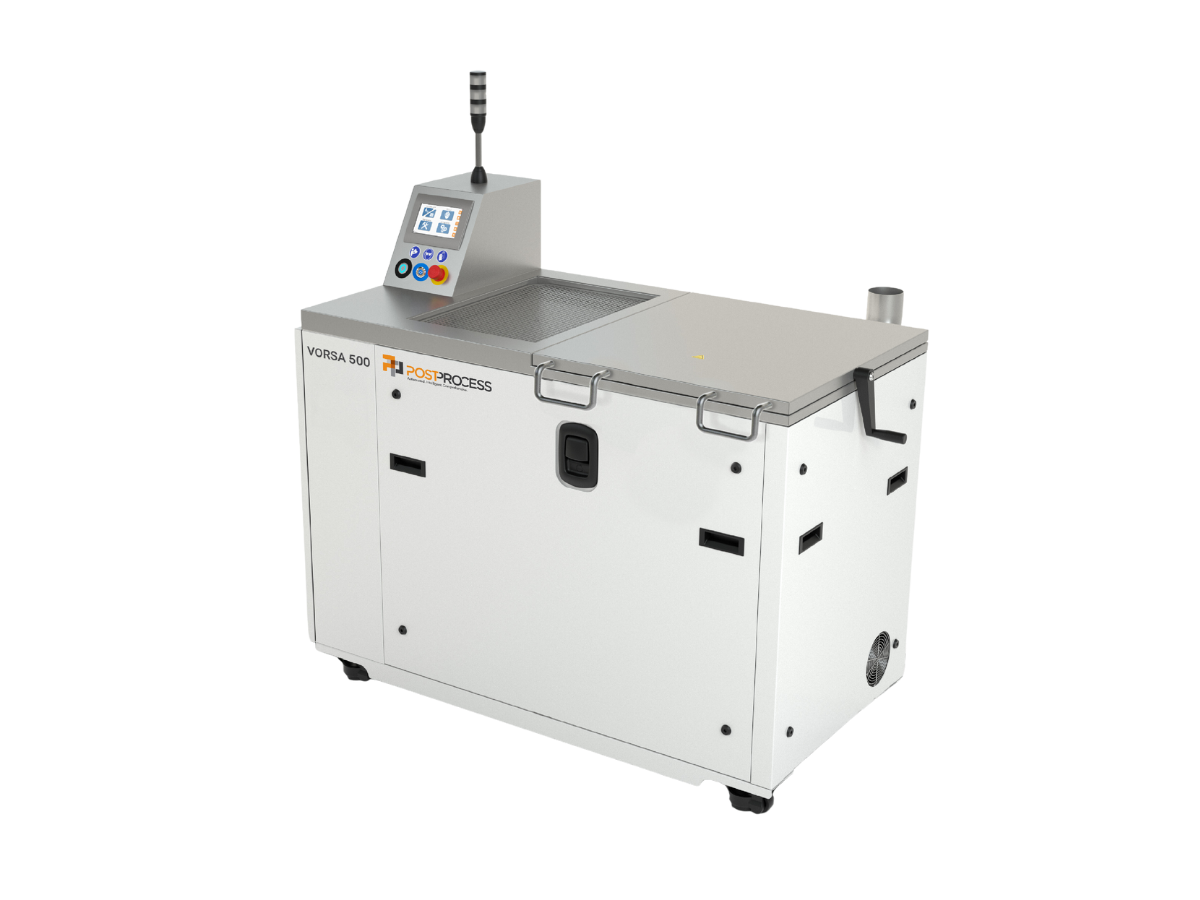

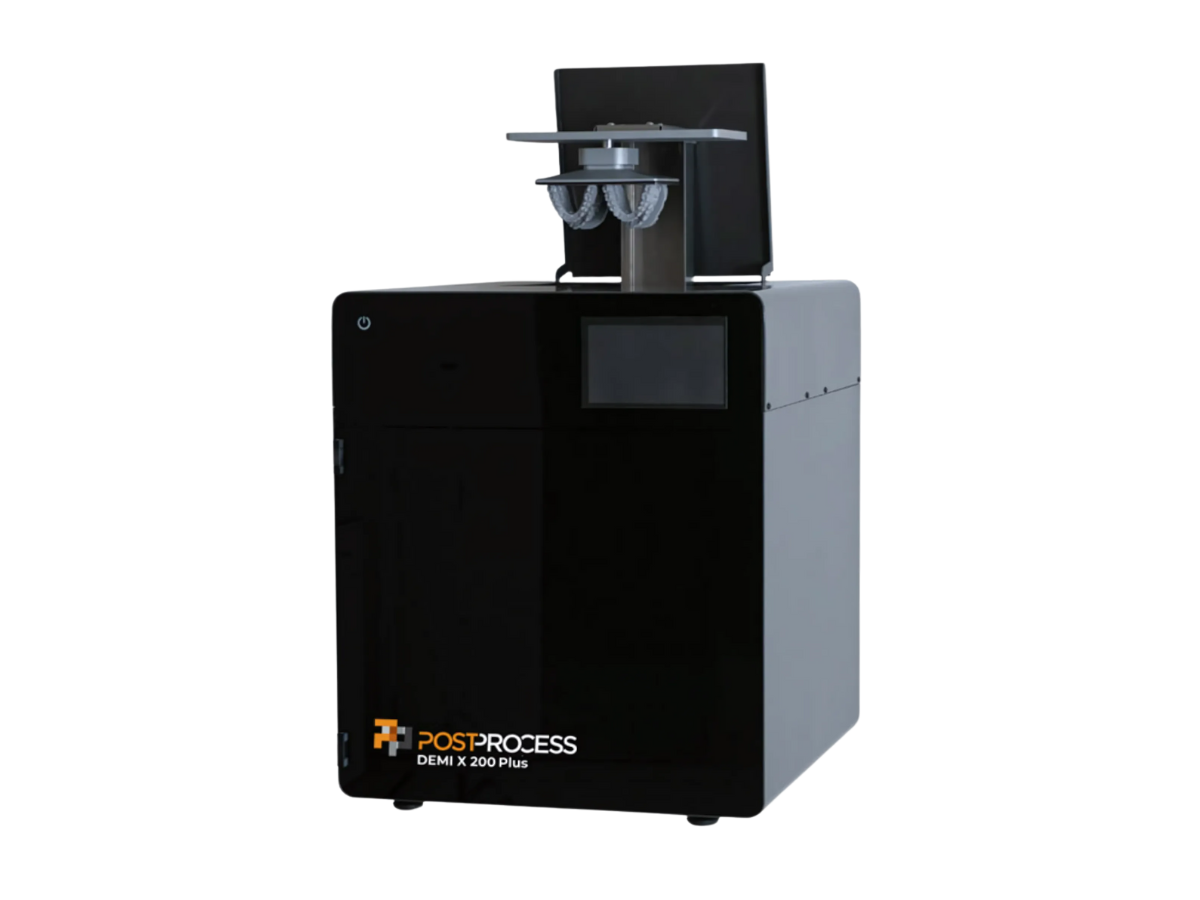

PostProcess Technologies® is a US company based in Buffalo, New York. PostProcess® offers an exceptional range of different highly automated post-processing solutions for a variety of different 3D printing technologies to reduce production times and minimize labor.

Daniel Hutchinson, founder of PostProcess Technologies®, recognized as early as the early 2010s that while 3D printing itself was highly autonomous, post-processing still took a significant amount of time. To eliminate this problem, he founded PostProcess Technologies® together with other pioneers in the field, and shortly thereafter, development of the first post-processing solution began.

This would be named DECI™ and launched in 2015. This system allowed FDM support structures to be removed quickly and automatically, resulting in significant productivity gains, especially in 3D print series production. In the years that followed, PostProcess® launched a range of highly automated post-processing solutions that focused on different post-processing steps and different printing processes – from surface finishing of metal components to cleaning of resin components.

In order to be able to automate not only the manufacturing process itself, but also all processes related to this manufacturing for our customers and partners, we needed a partner that offers automated post-processing solutions for many different printing solutions – and PostProcess® has more than met this requirement.

In addition to its systems, PostProcess® also relies on a combination of software and chemicals to deliver post-processing results that are not only fast or automated, but also of maximum quality. Thanks to its proprietary solvents and comprehensive software solutions, PostProcess® is an essential part of our strategy of making Industry 4.0 available to as many companies as possible.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy