3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

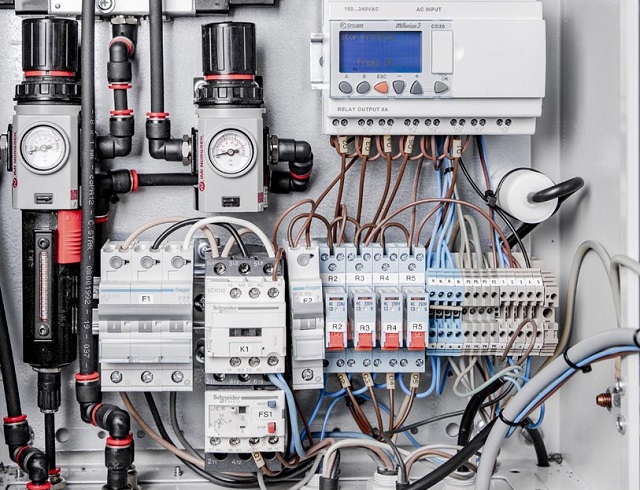

An industrial post-processing station for powder 3D printers that ensures a higher level of automation and the best ROI on the market. The AM Efficiency CCP-2 process delivers de-powdered, clean, and dust-free parts without static build-up.

The most effective method for post-processing and depowdering of parts produced with additive manufacturing technologies such as SLS, MJF, SAF or HSS. AM Efficiency CCP-2 enables the efficient production of high-quality finished parts with excellent repeatability by automating the part-finishing process.

Key features:

- 3-in-1 post-processing

- Small footprint

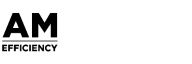

- Large drum

- Fast and versatile

There is no need to waste space and money on different devices that perform essentially the same function.

1. De-powder the components with the cleaning media and the preset cleaning program.

2. Switch to the "clean and color" blast media to achieve a uniform, beautiful dark gray color on your parts.

3. Switch to the polishing media and start the program to polish the parts until they have a flawless and shiny surface. Surface quality is critical for the most delicate components.

The AM Efficiency CCP-2 has an amazing cabin volume of 990 liters and a drum volume of 65 liters.

To enable an efficient workflow, the AM Efficiency CCP-2 is equipped with a removable drum that can be easily transported to the next step of post-processing after the operation.

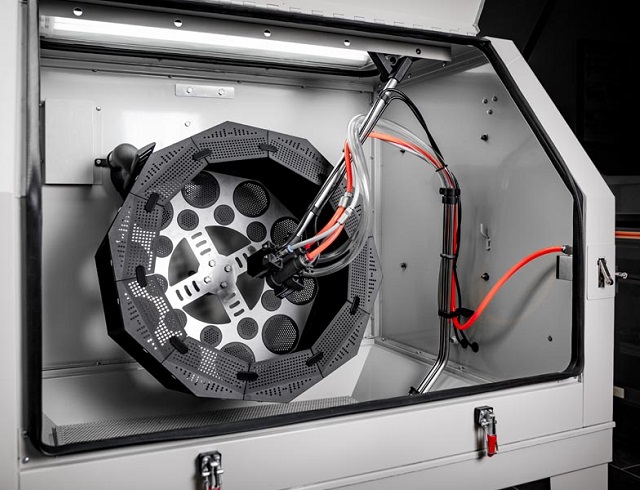

Am Efficiency CCP-2 finishing stations feature a unique patented extraction and separation system. This gives the system a major advantage in several ways, as cleaning powder bed 3D printed parts requires the removal of large amounts of loose powder. Conventional blasting systems are not designed for this task. AM Efficiency CCP-2 allows the powder to be separated directly from the abrasive. This allows the system to guarantee higher reliability and repeatability in production. Separated powder residues can also be better recycled.

Fully automated cleaning, dyeing, and polishing programs. Each program is designed for the most effective workflow. Each program includes a series of blasting, ionization, and extraction phases and ensures printed parts are free of static electricity and dust.

Whether you have a smaller desktop SLS 3D printer or one or more large production lines, finishing your printed parts is extremely important for consistent part quality. AM Efficiency CCP-2 is flexible and can be used for different operations like cleaning, coloring or polishing.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy