3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

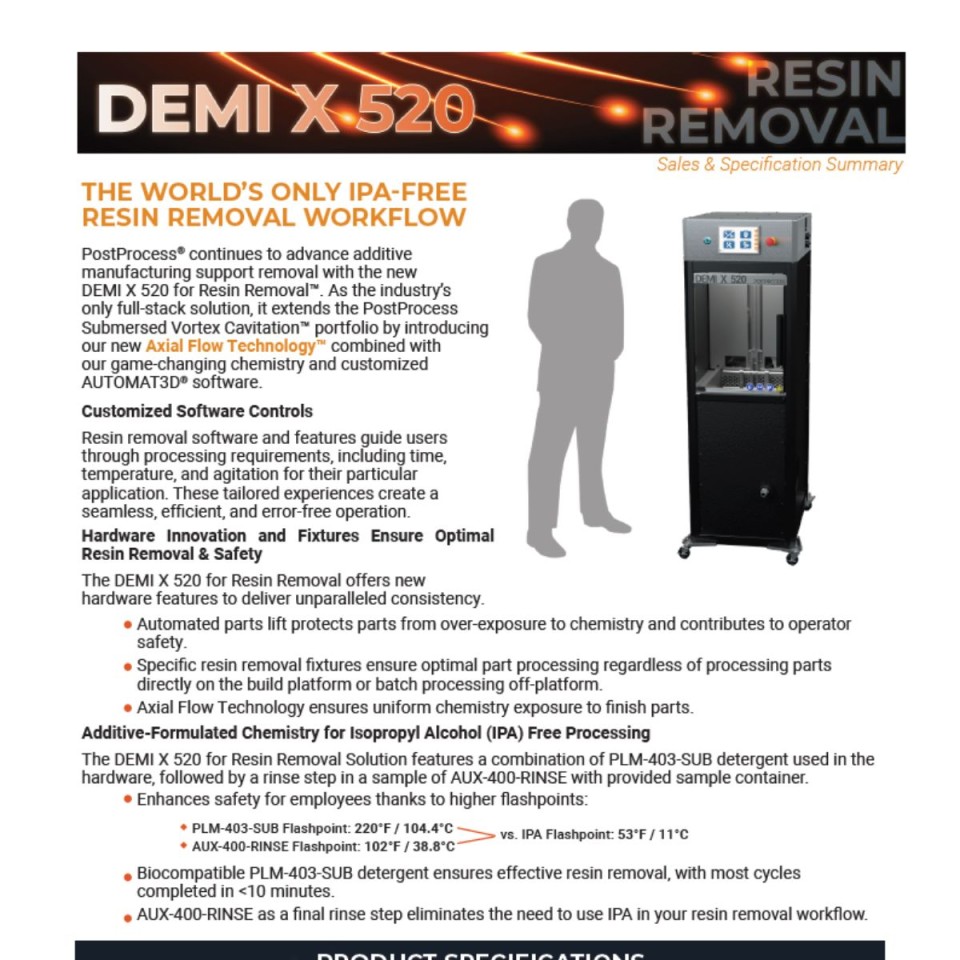

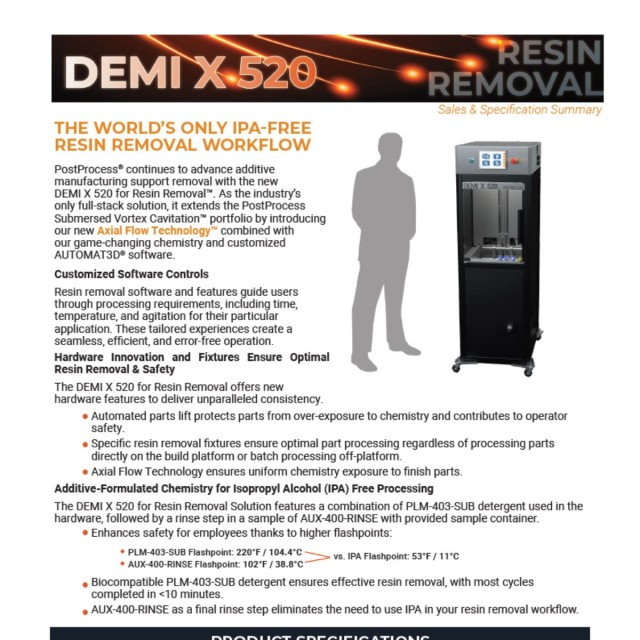

Increase your post-processing capabilities with PostProcess Technologies®' DEMI X 520 for Resin Removal. This cutting-edge system is engineered for precision and efficiency, offering exceptional results and establishing a new standard in automated resin post-processing.

PostProcess® introduces the DEMI X 520 for Resin Removal, further advancing additive manufacturing resin removal. This full-stack solution expands the PostProcess Submersed Vortex Cavitation™ portfolio with novel Axial Flow Technology™, innovative chemistry, and customised AUTOMAT3D® software that guides users through processing requirements, such as time, temperature, and agitation, according to their unique use.

Say goodbye to human interventions with the Automatic Lift System, which reduces the need for operator engagement while assuring uniform and efficient post-processing. With LED Chamber Lighting, you can gain real-time visibility into the post-processing path, providing instant feedback on the status of each component.

Technical Specifications:

Chamber Size: 360 x 360 x 380 mm

Maximum Liquid Tank Capacity: 91 liters

Certifications: CE, UL/CSE certified

The Axial Flow Agitation System is cutting-edge technology that allows you to change flow rates, increasing performance efficiency while reducing the risk of part damage. By giving exact control over the agitation process, this technology contributes significantly to the safety and optimization of processes. By optimizing flow, the Axial Flow Agitation System helps to improve outcomes in a variety of industrial applications, ensuring high-quality results and operational safety.

The PostProcess® DEMI X 520 for Resin Removal includes a number of innovative hardware features that improve its functionality and efficiency in resin post-processing. This cutting-edge system incorporates a catch tray for convenient residue collection, a detergent pump for effective cleaning, and an enclosed process area with safety interlocks to assure operating safety. Furthermore, the LED chamber lighting with RGB workflow status indication serves as visual indicators for monitoring processes. The system has ventilation mounting provisions, casters for convenient installation, and a stainless steel process tank for long-term reliability and easy maintenance. Additionally, customers can purchase additional fixtures to further tailor their post-processing system based on their individual needs and tastes.

The Automatic Lift System integrated with DEMI X 520 systems completely automates industrial operations. This revolutionary feature improves operations by automating the lifting process and effectively managing part exposure throughout the procedure. By reducing the need for manual operator intervention, the Automatic Lift System improves efficiency and precision in industrial processes, providing consistent and reliable results while increasing production.

Software-Driven Workflow Automation enabled by AUTOMAT3D® takes a user-centric approach, tailoring intuitive and guided experiences to match the unique needs of each application. This revolutionary software solution assures smooth, efficient, and error-free operation by presenting a user-friendly interface that simplifies difficult procedures. AUTOMAT3D® improves productivity and accuracy by streamlining workflows, minimizing errors, and optimizing overall performance, ultimately leading to higher efficiency and operational excellence.

PLM-403-SUB introduces an IPA-Free Workflow with Patented Chemistry, offering a biocompatible and environmentally friendly solution for washing and rinsing industrial parts. This innovative approach provides a safer alternative to traditional methods by utilizing patented chemistry that ensures compatibility with biological systems. When combined with the AUX-400-RINSE chemistry, PLM-403-SUB not only enhances the cleaning process but also eliminates the requirement for IPA in post-processing tasks. Embracing this advanced workflow enables industrial professionals to achieve superior cleaning outcomes while emphasizing safety, sustainability, and operational efficiency.

The PostProcess® DEMI X 520 for Resin Removal comes with a wide range of safety measures to ensure operating security and efficiency. It has an emergency stop feature to immediately cease operations in critical situations, a safety enclosure with a door sensor to monitor and control access to the process area, and a over-temperature safety system to prevent overheating problems. Furthermore, the system is CE and UL/CSE certified, indicating that it meets high safety criteria.

Unlock the full potential of your PolyJet prints with the DEMI X 520 - Polyjet, equipped to handle complex geometries effortlessly. Combined with the PLM-101-SUB consumable, this solution guarantees fast, safe, and repeatable support removal, enhancing throughput and part quality in every batch.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy