3D printers

High quality 3D printers

HealthcareToGo Dental Innovations Tour 2025 - North Germany

Secure your seat

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

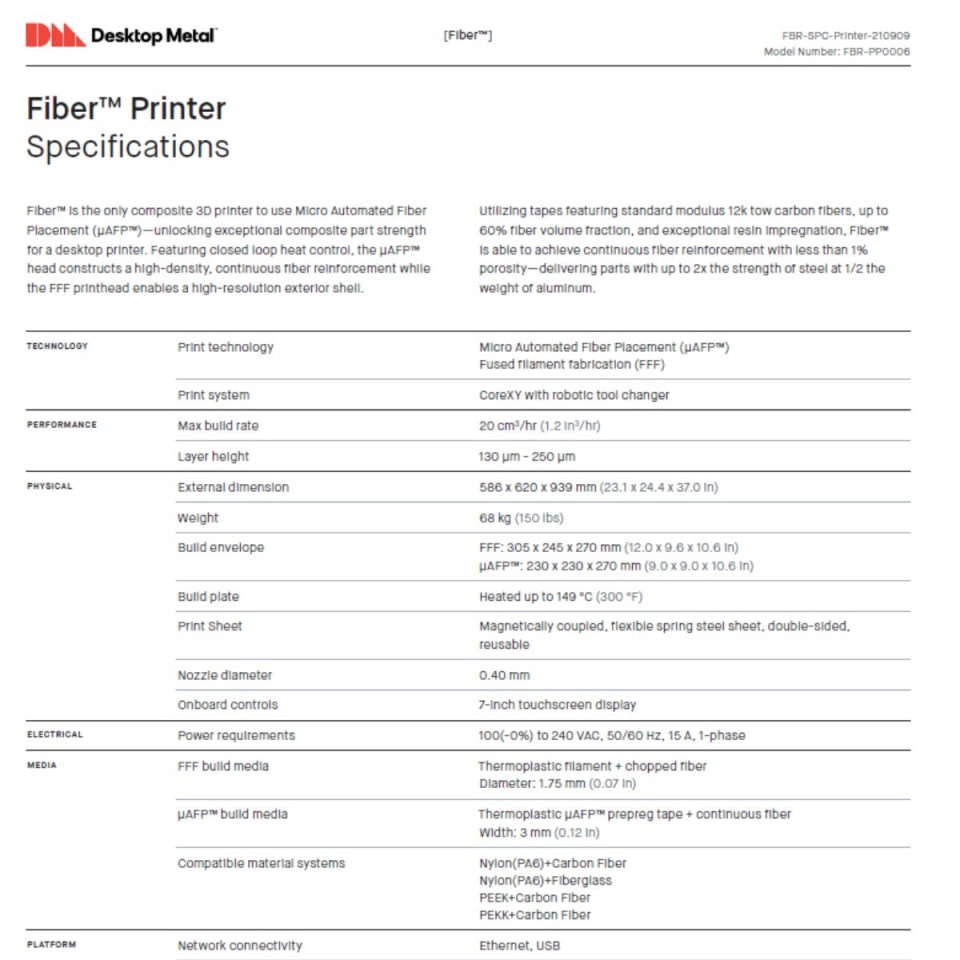

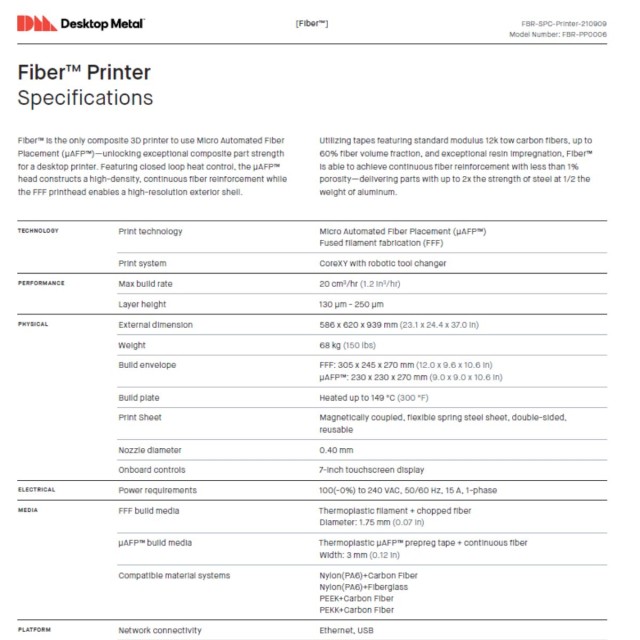

Desktop Metal® Fiber™ has revolutionized 3D printing for composites with its unique Micro Automated Fiber Placement (AFP) technology. The system combines the exceptional performance of continuous fibers with the accessibility of FFF printing.

The printer has three print heads: one print head, is responsible for inserting the fiber ribbon (μAFP ) along the load paths and reinforces the predefined areas of the part. The other two extrude thermoplastic filaments - the first is used for PA6 nylon, while the second is responsible for PEEK and PEKK.

The AFP process is controlled by two print heads. First, the selected base filament is extruded via the FFF print head. The carbon tape is then inserted via the AFP die head and embedded in the base matrix by a roller fixed to the print head. The software-controlled temperature monitoring system guarantees a material-locked connection of both components throughout, thus enabling unsurpassed component strength.

Save time-consuming changeover times and expensive tooling costs. Take advantage of the freedom of additive manufacturing, optimize your components and replace aluminum with fiber-reinforced high-performance polymers. Outstanding mechanical properties and heat resistance up to 250°C make these attractive team players.

In this patented process, the component is laminated along the load paths with a heavy-duty 12K tape. In this process, critical sections can be reinforced with a fiber volume fraction of up to 60%, which is absolutely tight.

In order to produce the part with approximately isotropic properties, the tapes are laminated at different angles. In the activated expert mode, the software automatically supports you with the fiber alignment and the percentage for defined load scenarios.

The Desktop Metal® Fiber™ system can be installed in just a few minutes and is ready for immediate use. Thanks to the predefined parameters in the standard setting, components can be quickly designed and manufactured according to the plug-and-play principle, even by "rookies". Of course, advanced users can also fine-tune the settings via the "advanced mode".

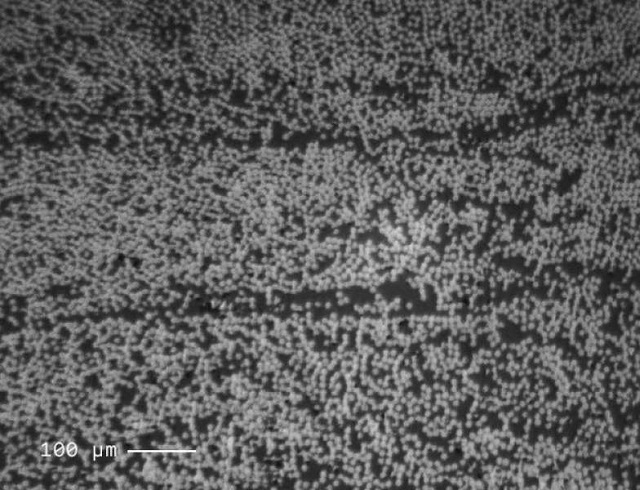

Producing high-quality lamination is an art in itself. It requires a great deal of know-how to optimally coordinate the individual parameters. The temperature within the buildup zone plays a key role and is, among other things, the guarantor for the material bond of both components. The μAFP tape head takes over this task. It ensures an ideally tempered buildup zone with constant. temperature and thus controls temperature management.

Thanks to unique materials, such as the 12K tapes and novel impregnations, the Desktop Metal® Fiber™ system can print components with high fiber volume fraction and 1% porosity, providing exceptional strength.

From consumer electronics and general mechanical engineering to the automotive industry, high-performance polymers (PEEK / PEAK) are very popular and are now gradually replacing aluminum materials.

After you have drawn your component, check the loading conditions and identify the load paths; because these are the ones that need to be reinforced.

Printing is carried out using the FFF process, in which plastic is extruded layer by layer. Short-fiber (carbon or fiber) nylon serves as the base material. Tapes made of glass fiber and carbon are used for reinforcement and are inserted via the AFP die head.

Compared to common plastics, components with short fiber content achieve extraordinarily high strength values, which are exponentially increased by inserting the tapes (carbon / glass fiber).

Composite materials are perfect for fixtures subject to mechanical stress thanks to their excellent mechanical properties, resistance to abrasion, and high fatigue strength.

The materials portfolio offers flame-retardant high-performance polymers that can be used permanently at operating temperatures of over 250°C while remaining incredibly stable.

Fiber™ is a fantastic alternative to aluminum components that are still conventionally manufactured. Increase your design freedom and increase your cycle times by saving weight through topology optimization.

ESD capability is an absolute must when it comes to applications in the electronics industry. The combination of PEKK and carbon fiber, meet the ESD standard and also provides exceptional mechanical and thermal properties.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy