3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

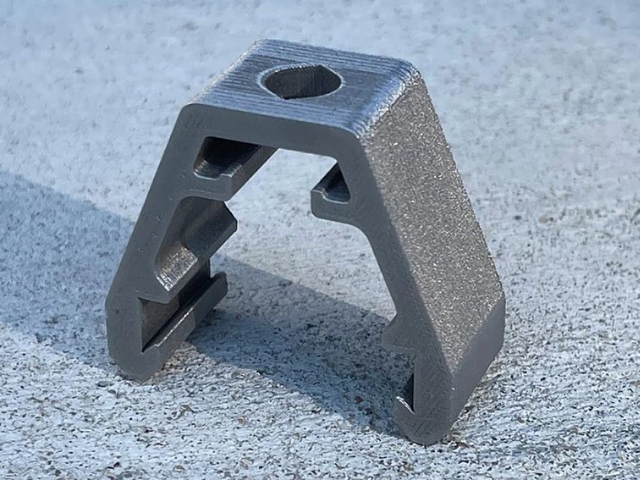

The Forge1 from Raise3D's MetalFuse series makes cost-effective metal 3D printing possible!

The Forge1 uses FFF technology to produce high-density metal parts for direct use after debinding and sintering. The printer has an optimized material supply system, a build platform optimized for metal filament printing and hardened nozzles.

In addition, the Forge1 offers optimized internal print parameters, process control, toolpaths and print calibration specifically designed for metal filaments.

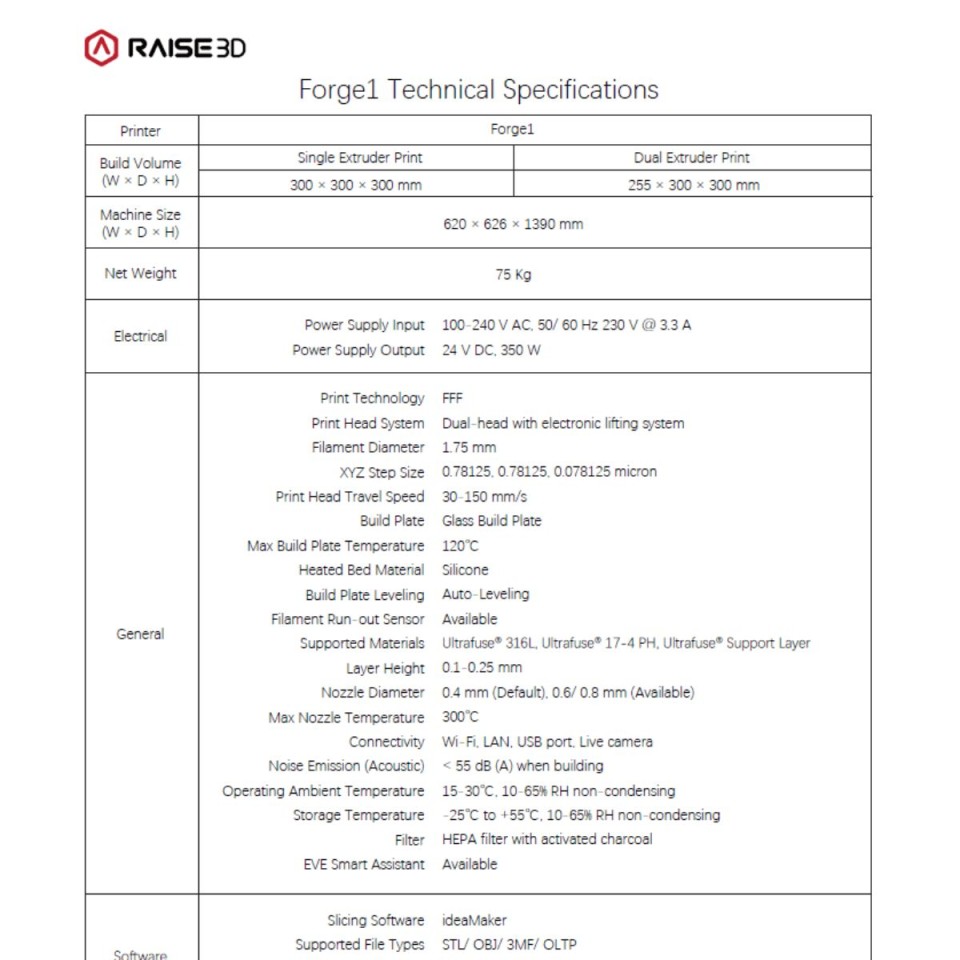

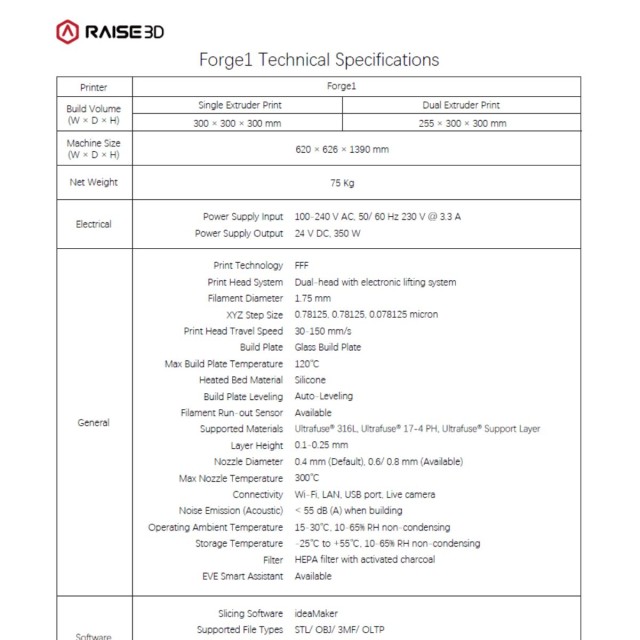

Technical specifications:

Single extruder build volume: 300 x 300 x 300 mm

Dual extruder build volume: 255 x 300 x 300 mm

Nozzle diameter: 0.4 mm (standard); also available with 0.6 mm and 0.8 mm

Maximum nozzle temperature: 300 °C

The new material feeding system of the Forge1 significantly reduces the resistance of the filament, which reduces the torque of the extruder head by up to 3 times. This provides an increase in success rate and repeatability, and also increases printhead life.

The Forge1 features optimized internal print parameters and improved process control designed specifically for metal filaments. It also features an improved offset calibration process that runs with the metal special edition Boot Assistant, allowing for individual left and right nozzle calibration.

The Raise3D Forge1 replaces the classic drag chain with a light cable, which reduces the weight of the extruder and allows the center of gravity to be kept permanently in the middle during printing. This ensures more stable print quality.

The hot-end of the Raise3D Forge 1 can be removed without tools, making maintenance or replacement easy. The front extruder cover can also be easily removed, which means that any problems (e.g. filament jam) can be pinpointed.

The Forge1 has a build platform with an improved construction to meet the demands of metal filament printing. Compared to the Pro3, which uses a coated metal sheet as the build platform, the Forge1 uses a high-precision glass plate made of calibrated glass, with amazing properties compared to normal glass.

The built-in HD camera is directly connected to the RaiseCloud and ensures that the printing process in the Raise3D Forge 1 can be continuously monitored remotely.

The Forge1 also has a latest generation CMOS sensor, which ensures high image quality.

The Forge1's integrated air flow manager on the back improves both air circulation and heat dissipation. As a result, there is always a stable environment within the pressure chamber.

Filtering and cleaning of the air inside the pressure chamber is also possible thanks to the built-in HEPA air filter.

The power failure function of the Raise3D Forge 1 ensures that a printing process that was unexpectedly stopped (e.g. due to a power failure) can be continued from the point at which it was interrupted.

The extruders also have a filament run-out sensor that warns the user when the filament is almost empty.

The Forge1 is complemented by the ideaMaker metal edition. This software automatically generates and compensates for dimensional shrinkage during sintering. It can also predict the time of the debinding and sintering process, has layer isolation support, a metal 3D printing specialized function for planning support column break points, and the printing profiles specialized for BASF metal filaments.

Thanks to the 7-inch touch screen, including on-screen help and visual model options, it is easier for the user to operate and manage the printer and the entire printing process.

The Forge1 has an integrated EVE assistance system that contains a list of common printing problems and how to fix them.

To ensure that maintenance work on the printer is carried out in good time, the EVE assistant offers the function of regularly reminding the user of necessary maintenance. It also helps reduce maintenance time and associated costs for more effective maintenance.

With the MetalFuse system, which will be available later this year, it will be possible to do the entire printing and post-processing process using only Raise3D equipment.

The D200-E Sintering Furnace and the S200-C Debinding Furnace in combination with the ideaMaker Metal Edition allows the user to slice, print, debind and sinter the print jobs to go from the digital model to the full metal part.

The Forge1 was not only optimized for the production of complex geometries, but also for reducing the weight of components. This allows the automotive industry to produce lighter components for more efficient fuel use.

From proof-of-concept prototypes to high-value consumer goods, the Forge1 gives you the edge in the competitive consumer goods marketplace.

The Forge1 enables strong and lightweight components that can withstand millions of work cycles.

Rapid prototyping for testing at low cost and short wait times make the Forge1 an excellent choice to achieve production volumes of all sizes of custom parts.

The complete control over geometry, material and specific designs based on patient-related data, which the Forge1 offers, enables more individualized treatments, simplifies biomechanical reconstructions and ensures faster implementation of innovative therapy methods.

With the Forge1, complex components can be produced without additional molds, tools, etc.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy