3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

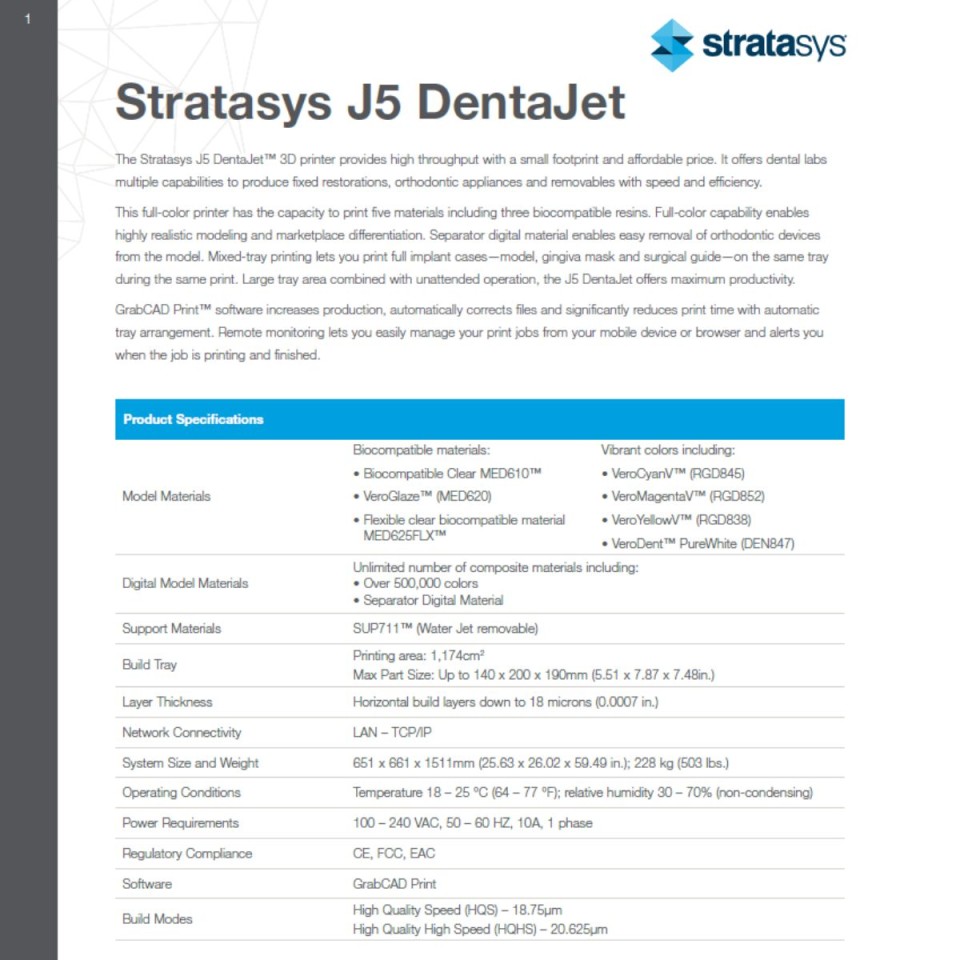

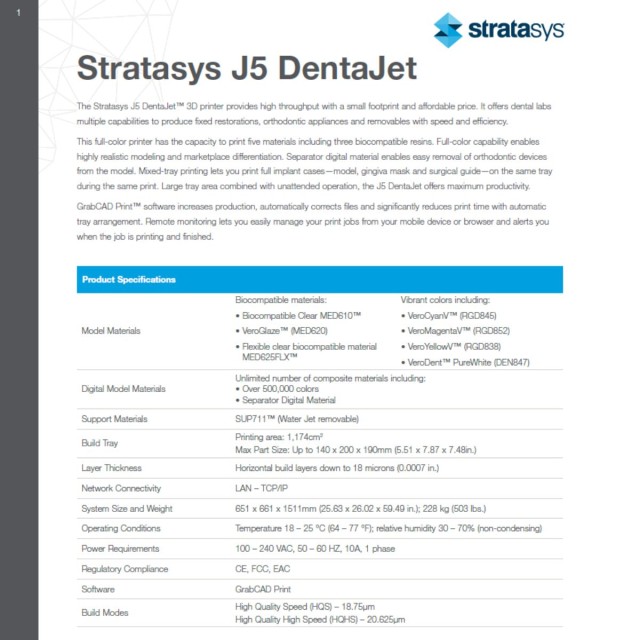

The J5 DentaJet™ is made to be as efficient as possible, with a big capacity rotating print tray inside a compact design. Produce even more different dental parts than the J3 DentalJet™ with fewer changeovers in a single mixed-tray print that is realistic, precise, and accurate.

PolyJet technology invented by Stratasys® used in the J5 DentaJet™ works well for complete colour realism and great precision while creating dental multi-material mixed trays with up to 5 different materials simultaneously; 2 more than the J3 DentaJet™. Similar to inkjet printers, PolyJet printers employ a similar procedure to construct models, but instead of jetting ink, they jet layers of curable liquid photopolymer, or resin, onto a build tray and each layer of curable liquid photopolymer is hardened with UV light before the next layer is laid.

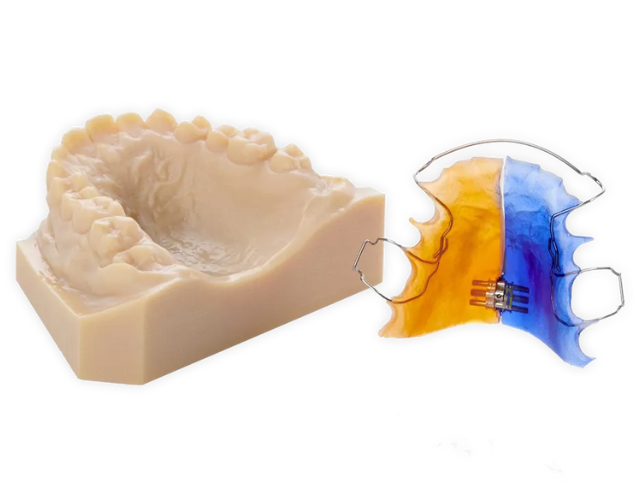

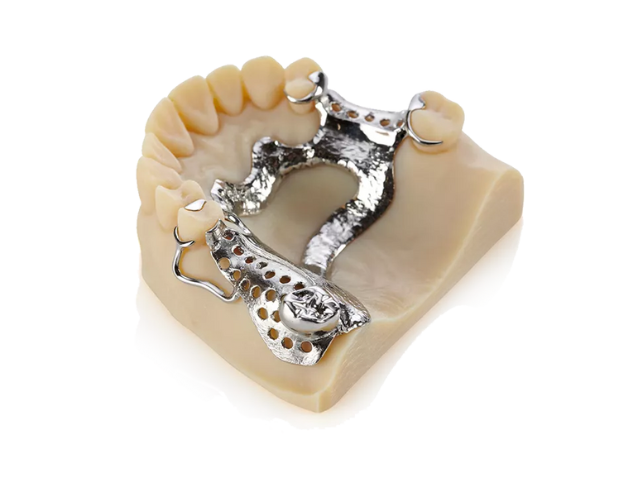

With the advanced materials printable on the J5 DentaJet™ that has superior digital dentistry and orthodontics create a range of precise models for implants, orthodontics, removable devices, and associated applications such as models (C&B, implant, orthodontic, removable, maxillofacial), full colour models using 3shape workflow, surgical guides, gingiva masks, TrueDent dentures and temporaries, indirect bonding (IDB) trays, RPD frameworks, custom impression trays and try-ins with consistency and exactness. The Stratasys® J5 DentaJet™, lets you deliver on a broader variety of scenarios quickly and effectively compared to the J3 DentaJet™. Fill a tray with a variety of prints, then walk away.

Technical Specifications:

Max Part Size: 140 x 200 x 190 mm

Tray Size and Area: Round print tray with up to 1,174 cm2

Layer Thickness: Horizontal build layers down to 18 μm

Build Accuracy: 18.75 μm - 20.625 μm

The 360-degree print tray's huge capacity enables the manufacturing of more parts in greater quantities. Small- to medium-sized dental labs benefit from the compact footprint, which increases productivity.

In a single mixed-tray print, produce more dental parts using mixed materials. The J5 DentaJet™ can print up to five multiple materials simultaneously. Minimise the amount of printers or processes required to finish a task.

With the J5 DentaJet™, you can print with high resolution droplets and complete curing during printing, which removes distortions from post-processing and gives your components unparalleled accuracy.

Make use of colour printing's potential. Make incredibly lifelike mouth replicas for patients, or print monolithic, polychromatic temporary or dentures in a range of hues.

You can load a tray and leave the J5 DentaJet™ to work on its own. It needs less post-processing, fewer changeovers, and less touch time to load. The closed cartridge system eliminates uncured resin handling.

The J5 DentaJet™ comes with two build modes depending on your time-constraints and the acceptable quality you need. High Quality Speed (HQS) Build Mode enables 18.75 μm accuracy with the best detail printable and High Quality High Speed (HQHS) Build Mode enables 20.625 μm accuracy with minimal degradation to print quality.

Operating GrabCAD Print™ requires very little training. Automatic print arrangement can boost output while cutting down on print time. Prior to printing, determine how much time and material will be required for production. Print jobs can be scheduled and tracked remotely. Without requiring the use of external software, automatically correct files and send alerts when the work is printing and finished.

Call or email us and we will be happy to help you.

Using a smooth digital workflow, you can go from intraoral scanning to in-house manufacturing, printing full-colour study models, clear aligners or indirect bonding trays in three dimensions (3D).

Reduce the complexity of implantology while increasing output. Print biocompatible transparent surgical guides, soft gingiva masks, and rigid, opaque implant models all on the same tray in a single, unattended print session.

Automate the cast chrome partial process instead of using traditional hand wax-ups, which will save a lot of manual labour. Combine RPD frameworks and print models onto one mixed tray. It is also possible to produce dentures and partial try-ins using smooth, biocompatible materials.

Enable dentists to seat crowns and bridges in a matter of minutes. Eliminate delays and inaccuracies of manual labour, enabling faster production and higher quality models with fewer remakes.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy