3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The DECI Duo™ automates support removal and surface finishing with Thermal Atomized Fusillade (TAF) technology. This technology uses two perpendicular, single-axis jet streams of compressed air, detergent, and suspended solids to provide targeted blast sequences while rotating the part 360° for maximum surface exposure.

Long Description:

The patent-pending DECI Duo™ automates surface finishing for a number of 3D printing technologies such as FDM, Metals, Polyjet, SLS, CLIP, MULTIJET FUSION, SLA and many more. The DECI Duo™ offers rapid cycle times for even the most complex parts, including those with internal channels, organic shapes, and honeycombs, and is designed with a space-saving size that maximizes production floor space.

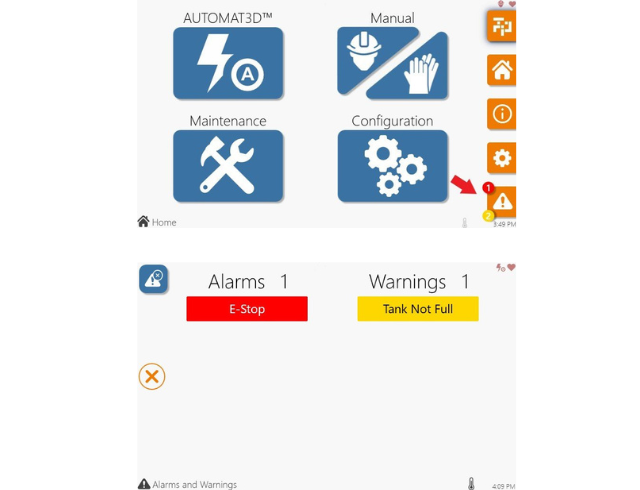

Through a combination of optimized energy, exclusive chemistry including detergents and suspended solids, the system is guided by proprietary AUTOMAT3D® software to provide the desired surface finish while preserving fine-detail part geometries. The DECI Duo™ thinks like a member of your team, monitoring and reacting in real-time to maintain optimal conditions with sophisticated features like pre-programmed preventative maintenance schedules, intelligent cycle time programming, and one-touch repeatability with recipes stored within the software.

Technical specifications:

Chamber Size (both nozzles): 380 x 380 x 304 mm

Chamber Size (top nozzle only): 380 x 380 x 380 mm

Maximum Liquid Tank Capacity: 76 liters

Maximum Suspended Solids Tank Capacity: 1.8 kg

Maximum Part Weight for the Turntable: 23kg

The DECI Duo™ not only removes support from a broad range of 3D printed materials using technologies such as FDM, DMLS, SLM, DED, Polyjet, SLS, CLIP, Multijet Fusion, SLA and many others, it also automates surface finishing using a number of suspended solids all in the same chamber making it an actual Clean In Place (CIP) system.

The DECI Duo™ comes with a fully welded stainless steel chamber that provides corrosion resistance, a hinged electrical panel design that allows for easy access for maintaining the controls and motor, an automated turntable to fixture parts to ensure parts are held in place during operation, a pass-through door capability, an LED lighted chamber, noise-reducing features for low dBA, an easy to maintain pumping system and casters for easy installation or relocation.

Ideal for the quickest cycle time on advanced materials such as resins, thermoplastics and metals, the DECI Duo™ finishes even the most complex parts including those with internal channels, organic geometries and honeycombs. Anywhere water can flow, the DECI Duo™ can clean.

The DECI Duo™ is engineered to utilize an automated Thermal Atomized Fusillade (TAF) technology that is configurable based on a specific operational need. This technology uses two perpendicular, single-axis jet streams of compressed air, detergent, and suspended particles to give focused blast sequences and rotate the part 360° for optimal surface exposure. This allows for easy support removal and surface finishing of 3D printed parts.

The DECI Duo™ can be operated in automatic and completely manual mode. It is important to keep in mind that the configured AUTOMAT3D modes are optimized for the most efficient operation. However, manual mode may be preferred when an operator is experimenting with new geometries or parameters.

Four primary settings can be adjusted in the Auto Setup screen; Air Percentage, Liquid Percentage, Time and Temperature. In addition, the speed, direction, and boundaries can be set for both the top and side nozzles. The turntable direction and speed can also be easily adjusted.

There are two options within Manual mode: Manual Run mode (used for troubleshooting or experimenting with new geometries or parameters) or Glove Port mode (circulates the solution through a stationary top nozzle - used when an operator prefers to handle the part for some of all of the processing.).

With pre-programmed formulas, AUTOMAT3D® removes the guesswork from post-printing and lowers operator labor time. Features include: Agitation algorithms, Intelligent cycle times, customizable settings, one-touch repeatability with recipes storage, media separation sequence among many other things.

Compliant with all OSHA regulations the DECI Duo™ comes with a number of safety features.It runs pre-programmed preventative maintenance schedules, Dosatron maintenance scheduling, emergency stop, door safety locks, external LED lighted chamber and many more.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy