3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

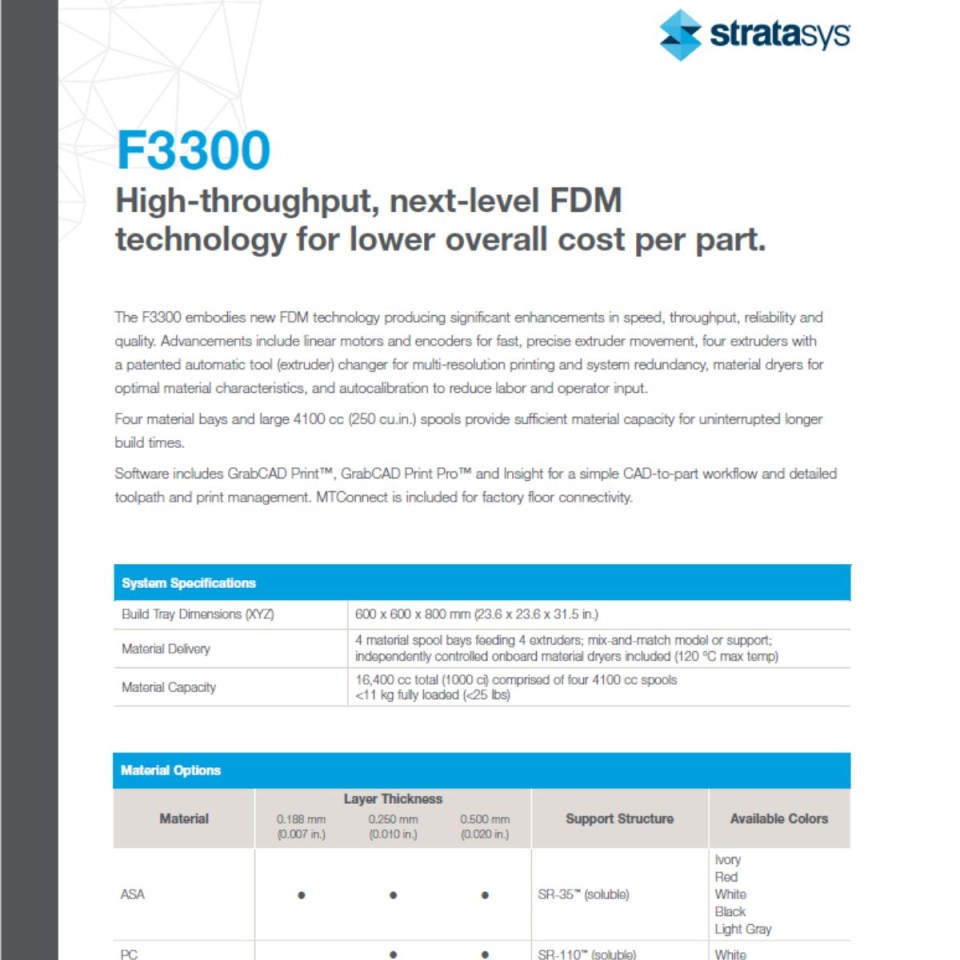

To reduce labor costs and increase economics, the F3300™ incorporates cutting-edge FDM® technology. The F3300™ reduces costs by offering a number of additional features over older printers, such as higher part yield and faster print speeds.

The F3300™ is designed for manufacturing with a lower cost per part model and brings a high-level product value. Boost your productivity with the four loaded extruder, fastest printing, quick changeover and high yield F3300™ FDM® 3D printer.

With an onboard material dryer, advanced extruders and better oven control produce stronger parts. With large spools being used in the F3300™, lower your material cost per cubic centimetre and open more applications. Increase uptime, reliability and part yield with its advanced process control.

Technical Specifications:

Build Volume: 600 x 600 x 800 mm

Layer Resolution: 0.188mm / 0.250mm / 0.375mm / 0.500mm

Volume per hour (max): 270 cm³/hr (16 in³/hr)

Acceleration: 1.2 G

Material Delivery Options: 4100 cm³ spools

The 600 x 600 x 800m large format FDM 3D printer comes with a fully heated chamber with variable speed fans and advanced variable speed airflow. The oven design includes patented modular thermal control for creating repeatable and consistent part quality at a wide range of temperatures up to 200 degrees celsius.

The four multizone and low mass extruders on the F3300™ are smart in the way that load cells monitor pressure, there is dual TC control for advanced melt flow of filament, it has quad drive control and has 2x faster extrusion. The new extruder design is hardened for composites and is designed for the hottest thermoplastics and flows at rates of up to 50% faster than any previous Stratasys® extruder. Mix and match extruders for optimal build parts.

The Stratasys® F3300™ comes with new Extruder drives with new Hot Ends for varying slice heights and uses new F3300™ build sheets.

Standard Hot Ends: N350 (0.188 mm), N500 (0.25 mm), N750 (0.375 mm and 0.5 mm), N410 (for support material)

Hardened Hot Ends: N350H, N500H, N750H

Build Sheets: Standard, Nylon and High-Performance options

The Stratasys F3300™ comes with 4 loaded extruders to reduce swap time that are auto calibrated that serves as redundant tools for reliability.

For improved process control and better part quality, four large 4100cc (250ci) spools can be dried at the same time to temperatures of up to 120 degrees celsius.

With a number of sensors, LEDs on extruders, two internal cameras (front - extruder view and back - full chamber view), a large user-friendly 15.6” (39.6 cm) UI with color coded indicator screens able to track all motors and processes and with it being MTConnect ready (having 429 data steams), monitoring and data collection has never been easier.

The overall design comes with a chip mounted in the handle and is tethered to spool with a mass of < 9 kg for a loaded spool that varies by material, comes at 4100 cubic cm per spool and is 406mm OD x 127 mm wide.

Call or email us and we will be happy to help you.

Use the F3300™ to transform the way fixtures and jigs are made. Make specialised, lightweight tools that enhance ergonomics and expedite assembly.

With the F3300™ you can guarantee your customers have access to replacement parts and cut down on lead times and expenses related to holding huge, out-of-date inventory.

Use the F3300™ to create parts for testing and validation, small batch prints, mass production, thermoforming, metal forming, etc. using multi-material or multi-resolution fixtures.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy