3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

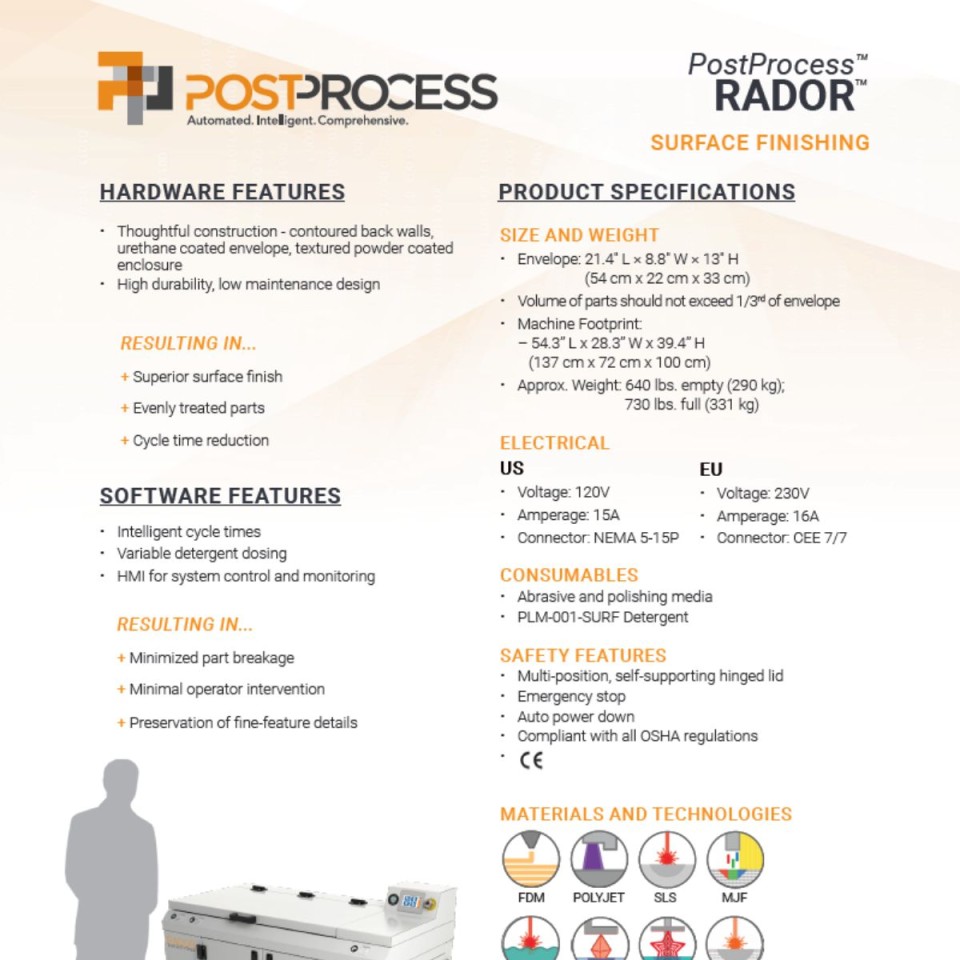

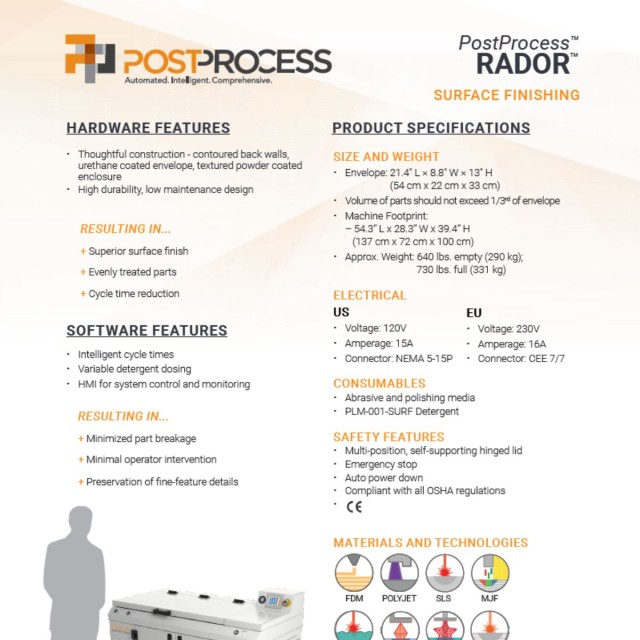

The PostProcess® RADOR™ Surface Finish system employs patent-pending technology called Suspended Rotational Force (SRF), which combines optimised energy with vertical motion using unique additive-formulated consumables to create the desired surface finish on each of your 3D components.

The PostProcess® RADOR™ meets surface finish requirements for a variety of 3D printed materials. The RADOR™ can polish surfaces from the following 3D printing technologies: FDM, SLA, CLIP, PolyJet, SLS, MJF, Metals, and many more.

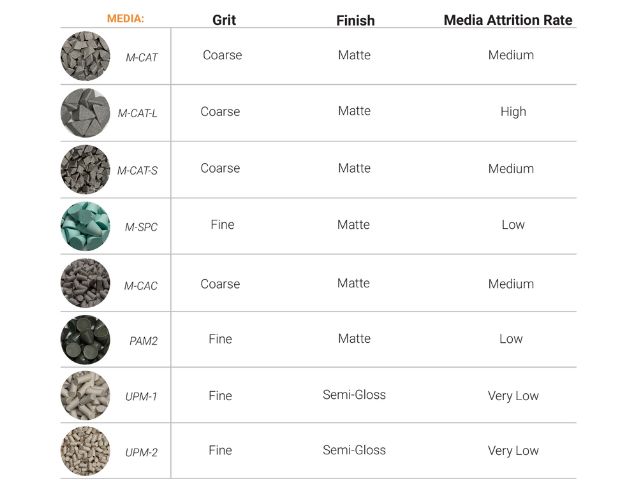

Polishing and abrasive media are available for varying applications and offer several different types of media that can be matched to your application.

Technical specifications:

Chamber Size: 540 x 220 x 330 mm

Maximum Supply Tank Capacity: 19 liters

Maximum Media Capacity: 0.023 cubic meters

The PostProcess® RADOR™ is an automated intelligent surface finishing machine for all 3D print technologies fo both plastics and metals. Print technologies include SLS, FDM, SLA, Polyjet, CLIP, MJF, DLP, DMLS, SLM, DED and many more. Designed solely for additive manufacturing the RADOR™ enables hands-free surface finishing with consistency and repeatability even for unique and delicate geometries.

With an 18.9 liter supply tank located under the main lid, the PostProcess® RADOR™ can hold the mixture of PostProcess detergent and water that will be dispersed by three chamber nozzles.

Available in different density and grit, ensure the desired finish and end product surface roughness for all print materials. With abrasive and polishing options deliver the correct amount of energy to produce the desired result. Some media includes: M-CAT, M-CAT-L, M-CAT-S, M-SPC, M-CAC, PAM2, UPM-1 and UPM-2.

The RADOR™’s patent-pending Suspended Rotational Force (SRF) technology creates a circulating motion while the part is immersed in a mixture of media and fluid. This technology applies even mechanical force with uniform contact and friction maintaining the parts dimensional consistency while keeping the fine feature detail intact.

The sediment tank, placed on the floor in the center of the enclosure, collects waste solution that has drained from the processing chamber. The user can choose between two Drain modes: Bucket Drain and Drain Plumbed. If Bucket Drain Mode is selected, the cycle will pause and request the user to drain the sediment tank. If Drain Plumbed Mode is selected, the sediment tank pump will activate without interrupting the cycle.

The RADOR™ can be operated totally manually. Keep in mind that all of the specified AUTO modes are optimised for maximum efficiency. However, manual mode may be preferable when an operator is experimenting with new geometries or parameters. Mechanical operations that can be controlled include the vibratory motor, nozzle pump, and sediment pump.

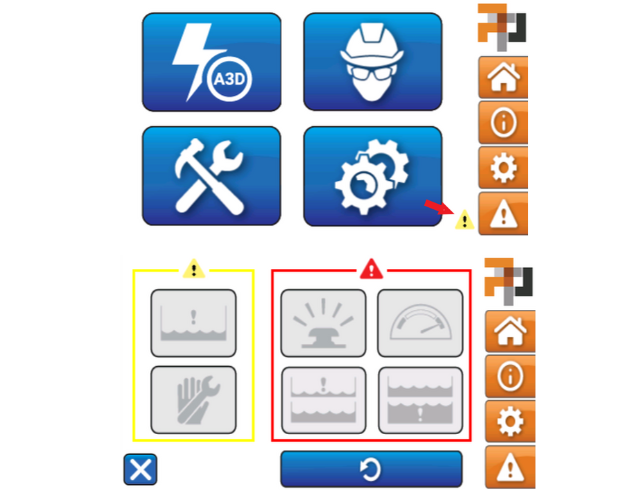

The RADOR™ software offers press and place surface finishing with quick select dosing frequencies to align part processing to various media options, geometries and materials. The RADOR™’s user friendly interface allows for flexibility with cycle times and disposal options.

Process monitoring with alarms and proactive warnings ensure your post-printing operation runs smoothly.

When a warning condition is activated (yellow), the system alerts the operator to a problem that must be addressed soon. Warnings include Low Supply Tank Level where you need to add detergent to the tank, Routine Service Maintenance where you need to perform maintenance and reset the timer among many other warnings.

When an alert condition is activated (red), the system alerts the operator to a problem that must be addressed immediately. Alerts include Emergency Stop, Sediment Tank Sensor Malfunction, Supply Tank Sensor Malfunction and High System Pressure alerts among many others.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy