3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

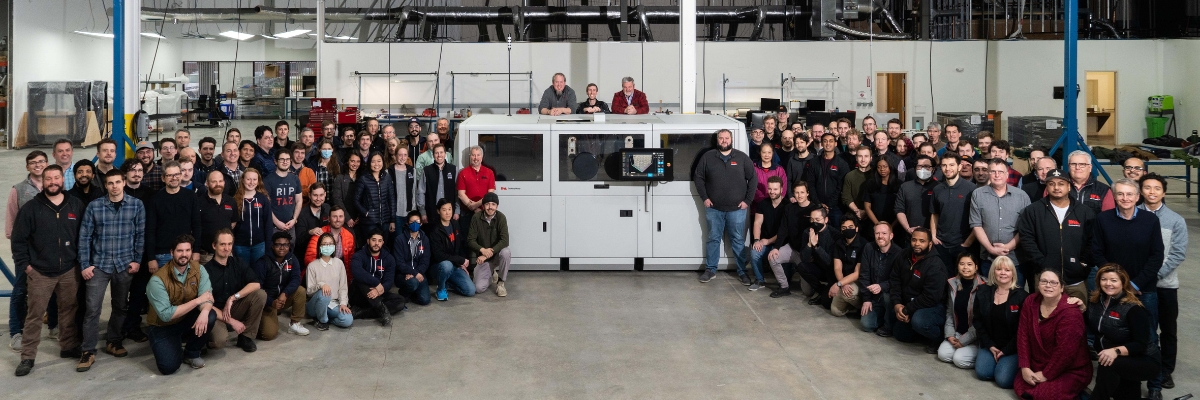

Desktop Metal®, Inc. is a company based in Cambridge, Massachusetts, that was founded in 2015. The company is one of the world's largest solution providers for metal additive manufacturing and has an unparalleled team of leading engineers and application experts who design and manufacture highly industrial metal printing systems.

Desktop Metal® was founded as a start-up by several experienced 3D printing specialists and was quickly able to attract investment from large companies such as Google Ventures, BMW and Ford with convincing ideas. With almost $100 million in funding in its first year of existence, Desktop Metal® developed its first printing systems – the Studio System™ and the Production System™ – which were launched in 2017.

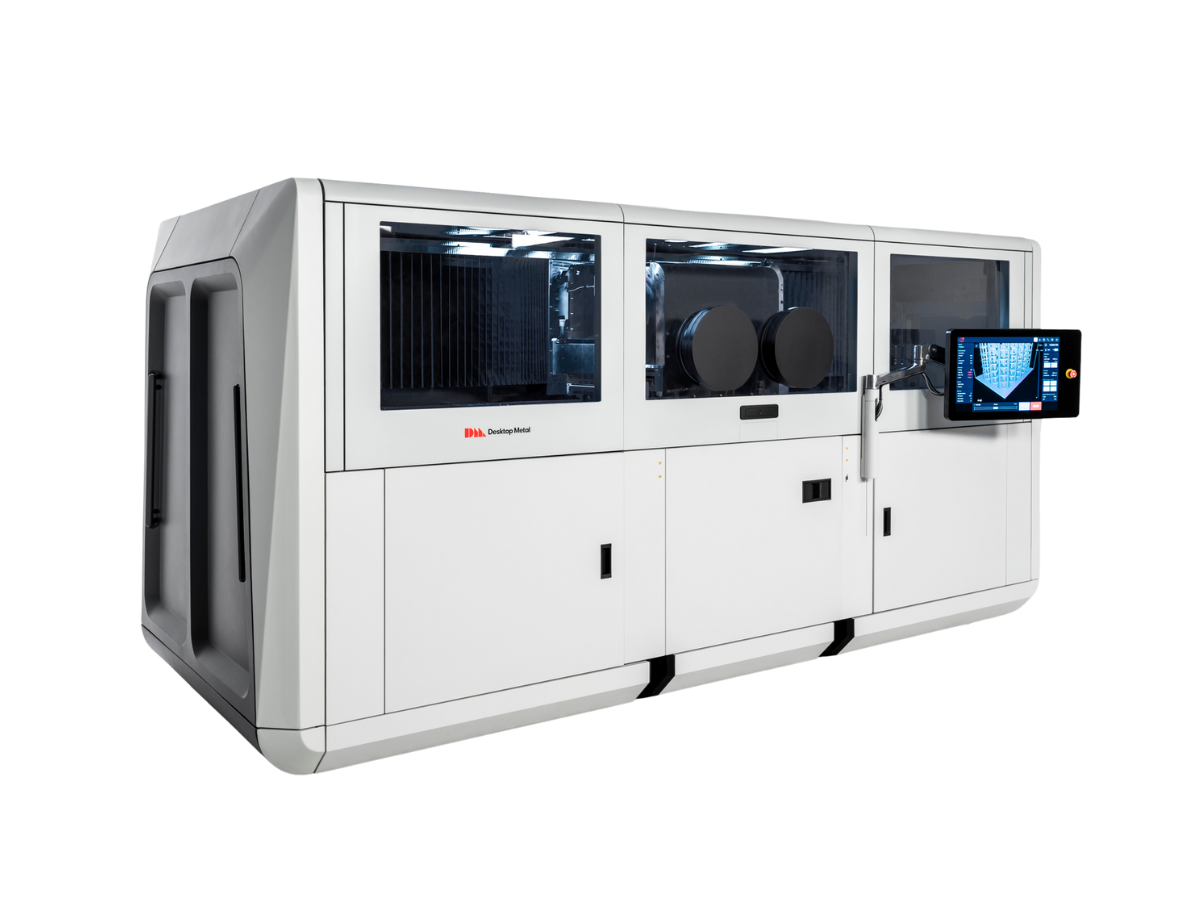

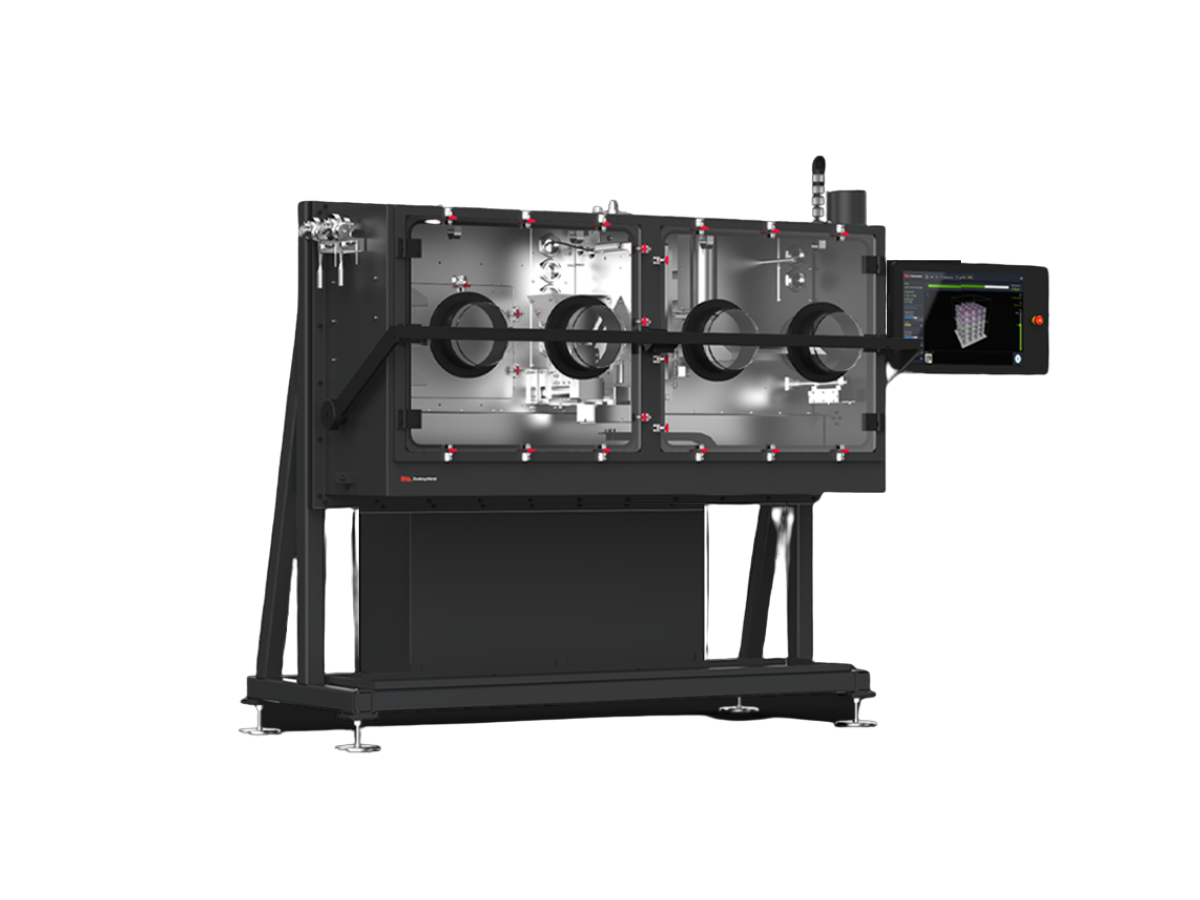

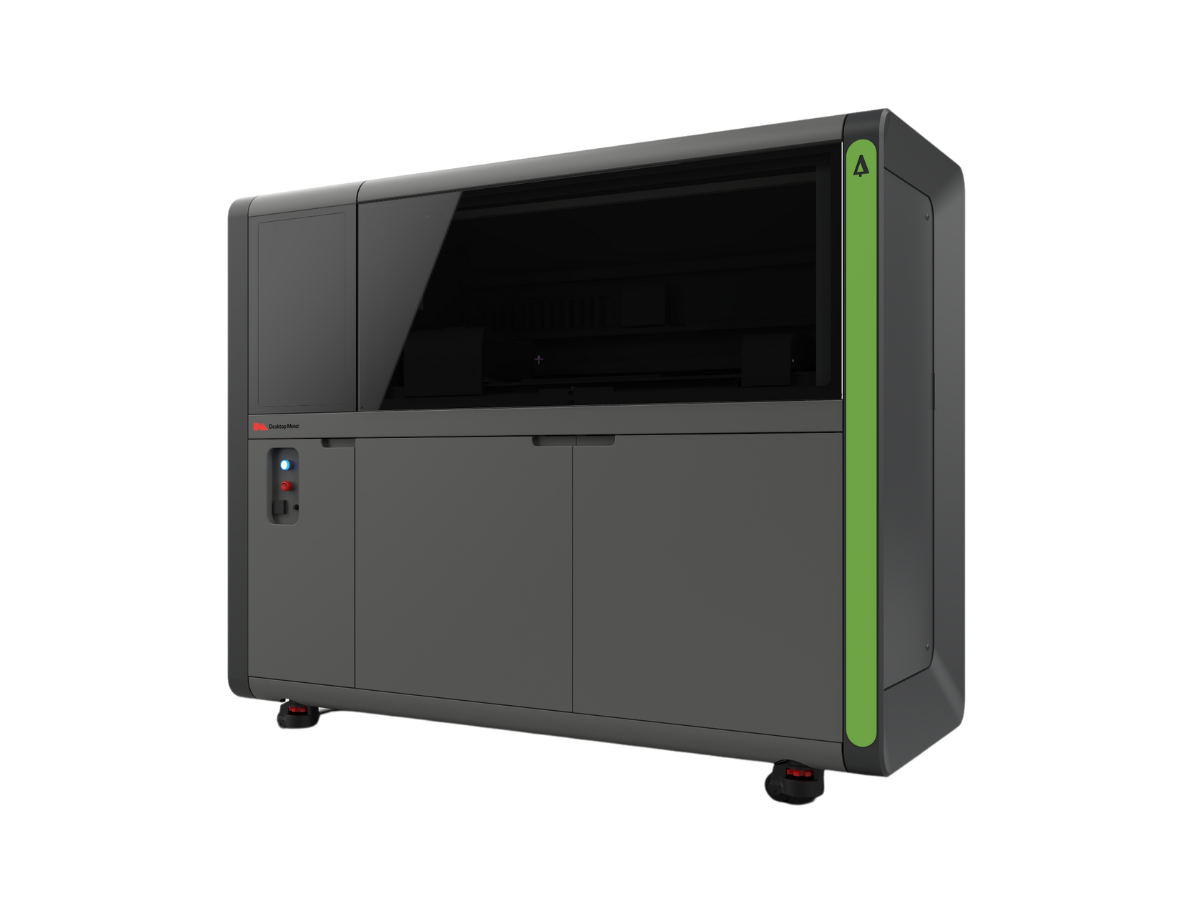

However, these two printing systems, which both used the Metal Binder Jetting (MBJ) process, were just the beginning. Over the next few years, Desktop Metal® developed a variety of other printing systems to meet the specific needs of different industries. Desktop Metal® now offers eight different printing systems – from the Production System™ P-50 for the series production of metal components, to the X-Series for manufacturing metal and ceramic components, to the Studio System™ 2 for office-friendly metal 3D printing.

With its wide range of different systems, Desktop Metal® provides an essential foundation for our portfolio, enabling industrial companies in the metal processing sector to take the step towards additive manufacturing.

With solutions for all potential stages in the product development cycle – from simple prototypes to end-use parts in small series and serial production – we can serve a wide range of companies individually and thus actively contribute to converting metal processing to additive manufacturing.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy