3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The InnoventX uses Triple ACT (Advanced Compaction Technology). It is equipped with a piezoelectric print head (256 nozzles) that is unidirectional but can be programmed to be bidirectional.

The most compact open binder jet 3D printer!

The InnoventX uses Triple ACT (Advanced Compaction Technology). It is equipped with a piezoelectric print head (256 nozzles) that is unidirectional but can be programmed to be bidirectional.

A 10-pound bag of standard MIM powder is all that's needed to get started, and the minimal build volume keeps ongoing operating costs to a minimum.

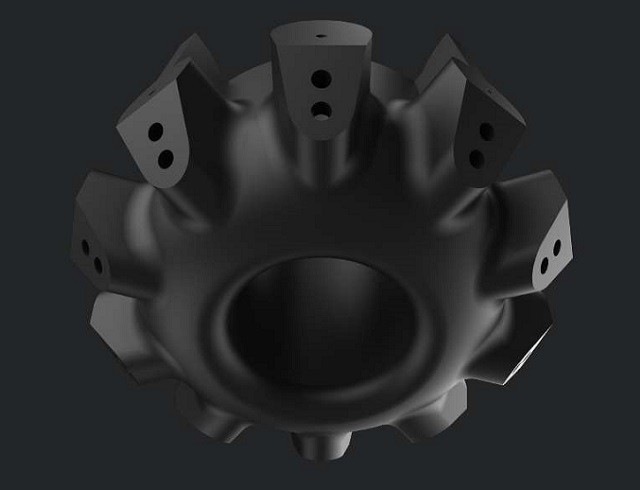

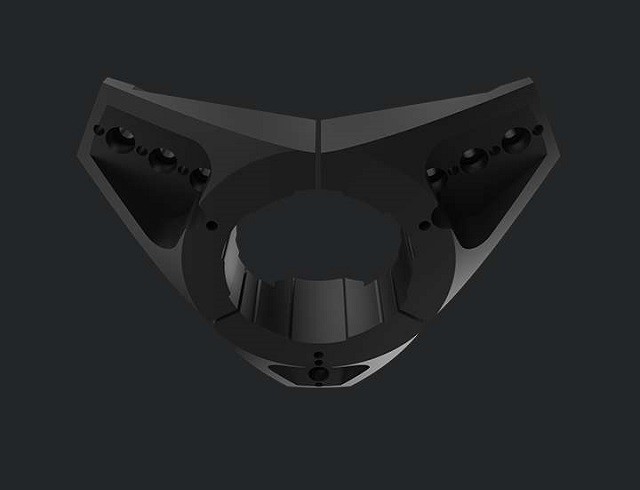

With the X-Series, you can mass-produce dimensionally accurate and dimensionally precise components. Tolerances can be less than 1% after optimal material adaptation and parameter setting - density can vary from 97% to over 99%.

Open platform with a D50 range from 3 to 100 μm for printing metal, ceramic, sand, and composite powders.

The unsurpassed surface quality on the X-Series is the result of optimally matching the Triple ACT system with the precise placement of the binder. Binder build-up and overspray can thus be avoided, resulting in exceptional edge sharpness and surface finish (4 µm Ra) on parts.

Metals, ceramics, and composites are just some of the materials in the X-Series portfolio. This versatility is achieved through the Triple ACT system, which allows the use of high- and low-flow materials, as well as small and large powder particles. The X-Series is used for processing ceramics such as silicon carbide and aluminum-infiltrated boron carbide, as well as stainless steels, tool steels, nickel alloys, aluminum and titanium alloys (B4C).

Call or email us and we will be happy to help you.

Additive manufacturing enables rapid functional prototyping of complex automotive components and on-demand tooling - increasing design flexibility, shortening product development times and streamlining production.

For consumer goods manufacturers, 3D printing is beneficial for both product development and production. During the development phase, designs can be quickly tested and feedback can be obtained from the market. Regionally coordinated, smaller quantities or even high batch sizes can be produced quickly and without tools.

The open system, offers students the opportunity to access different materials and gain experience accordingly. The advantages are used by a wide range of faculties and are very much appreciated.

With 3D printing, designers can simultaneously print and test multiple variations of a part to quickly optimize their designs. Thanks to greater design freedom, engineers are now able to design complex geometries that would be impossible to produce conventionally. Furthermore, components can now be combined into an assembly and manufactured in one step.

Equipment for the mining, iron and steel, machinery and plant engineering, refinery, pulp and paper industries all require mechanically highly stressable components with specific properties. With 3D printing, customer-specific parts can be produced without tools and usually do not require any post-processing.

By rapidly producing manufacturing tools such as jigs and fixtures and mold inserts, 3D printing helps shorten lead times and reduce costs, allowing companies to move quickly from finished design to production.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy