3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

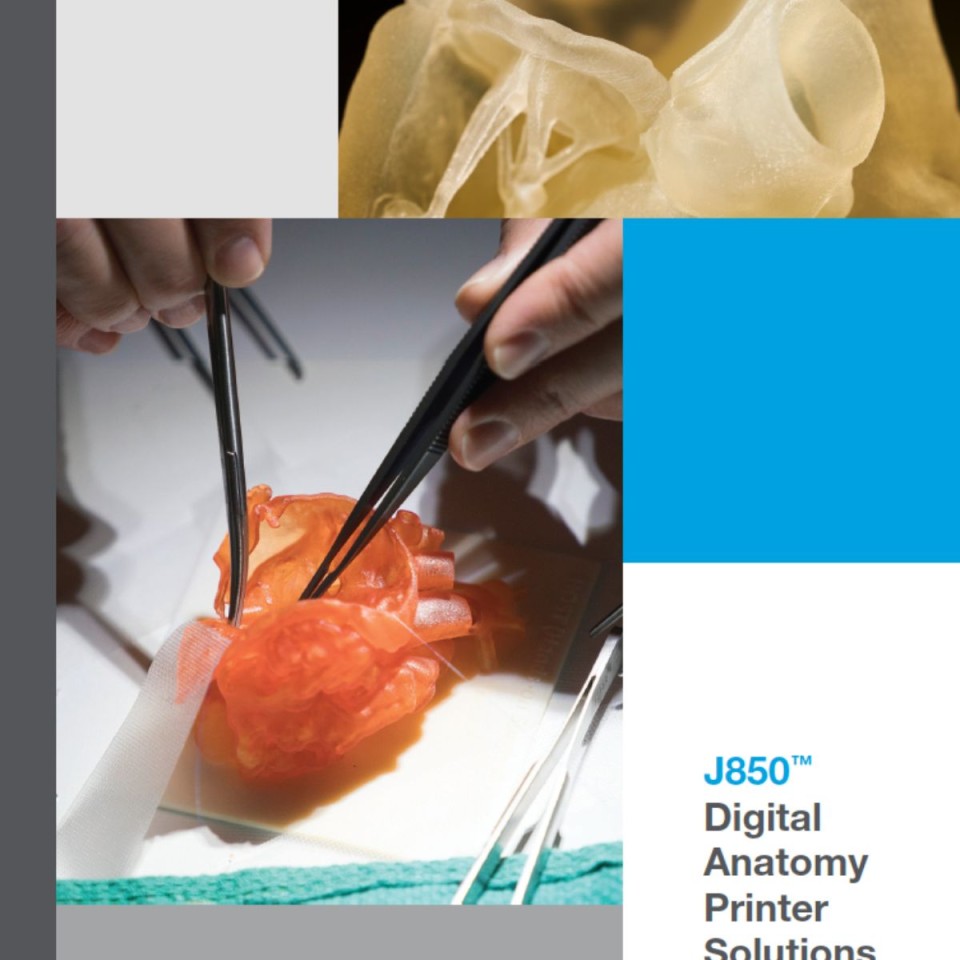

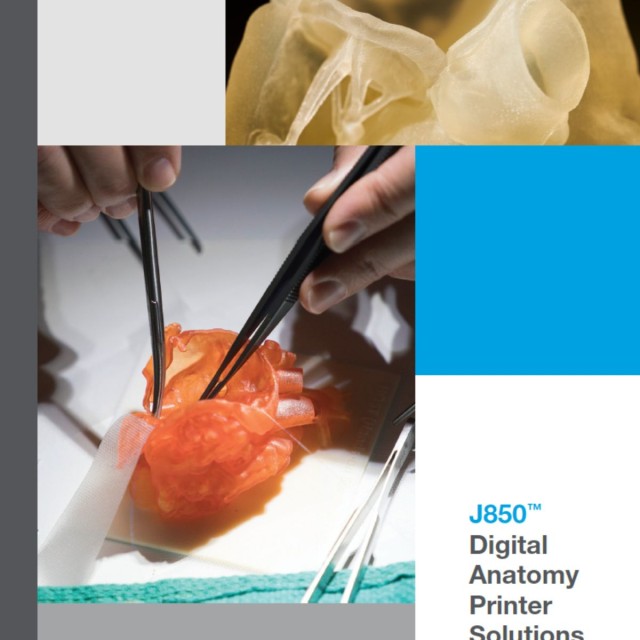

With unparalleled precision, realism, and functionality, the J850™ Digital Anatomy™ printer really brings medical models to life in terms of appearance and feel.

A major development in medical modelling, the Stratasys® J850™ Digital Anatomy™ 3D Printer enables researchers, medical device manufacturers, and healthcare providers to produce incredibly functional and accurate models of human anatomy for a variety of uses.

This printer creates 3D models that faithfully replicate the look, feel, and action of human tissue, bone, and vasculature using cutting-edge materials and software.

When full-color capabilities are required, advanced design tools let you specify transparencies, choose from more than 500,000 hues, and choose textures and finishes. Reduce the need for cadaver and animal labs so that you can teach and test anywhere, save money on purchases, and improve ethical procedures.

Technical Specifications:

Build Size: 490 x 390 x 200 mm

Layer Thickness: Horizontal build layers down to 14 microns

Build Modes: 4

The printer's capacity to produce 3D models that are remarkably similar to human tissue, bone, and vasculature in terms of appearance, feel, and activity is unmatched. Specialised materials like GelMatrix, TissueMatrix, RadioMatrix™, and BoneMatrix - which may be combined to produce hundreds of unique digital materials - are used to achieve this level of realism. 4 base materials provide more than 1,000+ anatomical presents.

The printer avoids the need for expensive physical specimen procurement, which may be both costly and logistically difficult, by keeping a digital inventory of anatomical models. Using 3D printed models also saves money on operating costs by eliminating the need for specialist staff and facilities for managing animal or cadaver-based labs. Because it can swiftly, reliably, and without the inherent unpredictability of physical specimens make highly realistic anatomical models, the J850™ Digital Anatomy™ printer can achieve up to a 70% cost savings. Easy scalability is another benefit of this digital method, since more models may be printed as needed with little overhead.

The J850™ Digital Anatomy™ 3D Printer contributes to more ethical practices in healthcare organizations and medical device companies by reducing the use of animals for surgical training and device testing. By using fewer animal models, companies can improve public perceptions of medical research and device development while also preserving their good name and fostering regulatory and public trust.

The J850™ Digital Anatomy™ comes with advanced design tools that allows you to choose from more than 500,000 colors when full-color capabilities are needed in order to define transparencies, and determine textures and finishes.

Up to seven different materials and additionally one support material can be printed simultaneously using the J850™ Digital Anatomy™ at once, allowing for the fabrication of parts with a wide range of colours and characteristics, such as stiff, flexible, transparent, and opaque materials. With this multi-material capability, customers can print jobs that mix many materials without the requirement for assembly or post-processing.

Four unique build modes are available on the Stratasys® J850™ Digital Anatomy™ 3D printer to accommodate a variety of customer requirements. The highest level of accuracy and detail is achieved at a resolution of 14 microns by using up to seven base and one support resin in the High Quality Mode. The High Mix Mode, which likewise allows up to seven base and one support resin but at a somewhat lower resolution of 27 microns, is the ideal mixture between quality and printing speed. The High Speed Mode employs up to three base and one support resin at a resolution of 27 microns for faster printing of concept models. Lastly, the Super High Speed Mode allows the fastest printing with a single base and support resin, which makes it perfect for quick iterations even if it compromises some resolution at 54 microns.

The J850™ Digital Anatomy™ comes with a built-in workstation with a touch screen that doesn’t require a keyboard or mouse, it has a removable tray for easy cleaning and swapping and it has a 16 4kg cartridge capacity that auto swaps when low on material.

In just a few easy clicks, create what you need. By selecting the preferred anatomy from the more than 100 options available in the preset anatomy menu, you can easily print precise and realistic models. Modify characteristics to resemble diseased or healthy tissue. Ensure post-processing is simple and speedy and effortlessly remove gel support material from intricate vessels.

Call or email us and we will be happy to help you.

New medical devices can be clinically tested on a benchtop using the printer's incredibly realistic 3D anatomical models, which faithfully replicate the look, feel, and behaviour of human tissue, bone, and vasculature. Product engineers may swiftly and easily create, test, and validate innovative medical devices in a controlled setting using these anatomically correct models instead of relying on cadaver or animal-based testing. The models enable comprehensive testing and validation of device performance under many physiological scenarios by simulating a broad variety of diseases, from healthy to diseased settings.

The J850™ Digital Anatomy™ printer produces incredibly lifelike 3D printed anatomical models that let medical practitioners hone their surgical techniques in a low-risk, controlled setting. Trainees can practice procedures like guide wire and catheter insertion, valve replacement, and other cardiac and vascular interventions thanks to the models, which faithfully mimic the appearance, texture, and action of human tissue, bone, and vasculature. Medical training may now be conducted with an unprecedented level of realism because to the printer's capacity to build models with functional elements like valve leaflets, annuli, and variable vessel compliance. As a result, trainees can get haptic feedback that is clinically relevant and gain a deeper understanding of the anatomy and physiology they would encounter in actual surgeries.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy