3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email3D printing basically involves three process steps: print job preparation, the printing process itself, and post-processing. Industrial printing systems can handle certain phases autonomously within these process steps, but for others, automation by the printer itself is not possible, resulting in lost productivity, especially at very high volumes.

The solution to this problem is provided by Additive Automation, which started out as an in-house development project but has since grown into one of the largest solution providers for fully automated production cells. The magnum opus of this development work is the V1 production cell, which can be used to automate a large number of processes that are actually manual, thus delivering 24/7 production and providing the ideal solution for very high volumes.

The main component of the production cell is, of course, the robotic arm, which does most of the work.

This six-axis arm offers a reach of 1,400 mm in all directions, can carry up to 10 kg in weight, boasts outstanding precision and advanced safety features, and achieves joint speeds of up to 225 degrees per second.

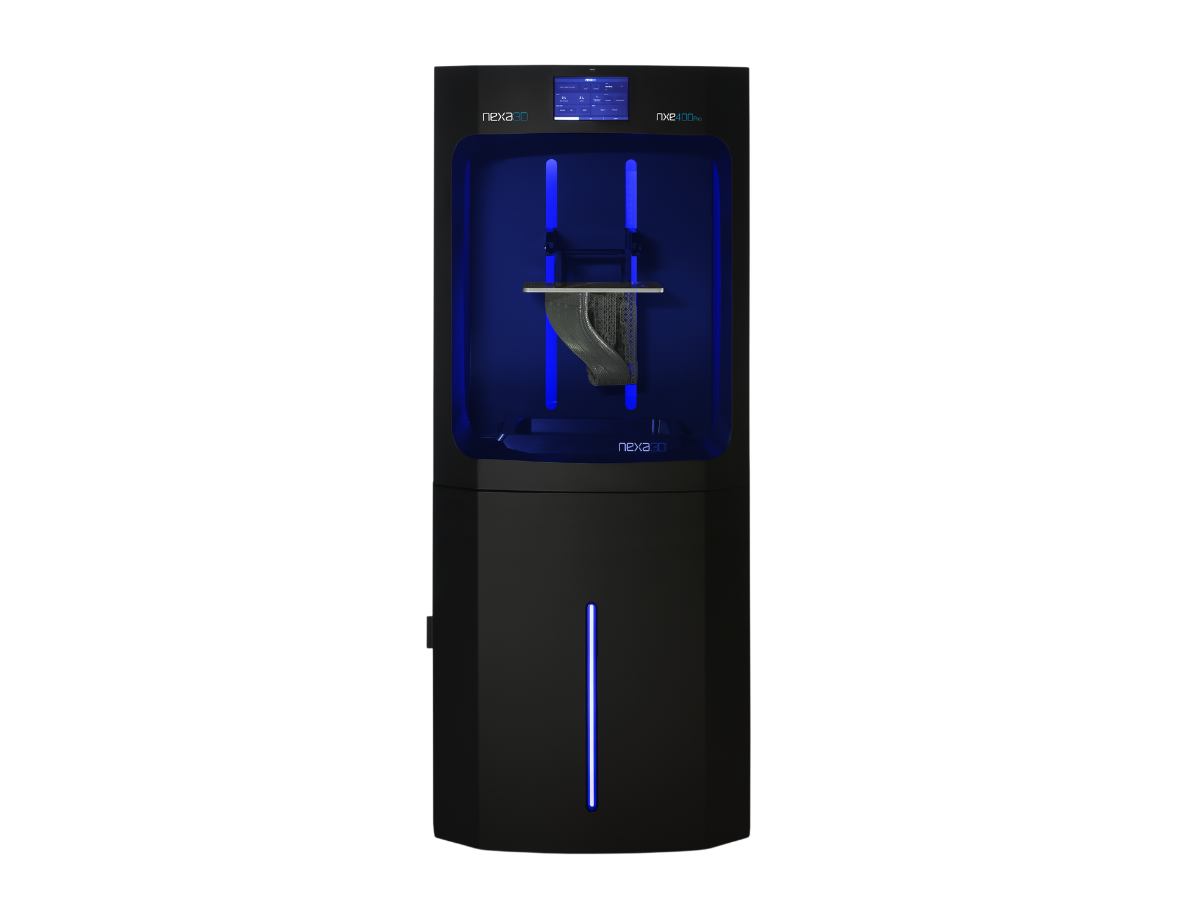

Of course, automation of additive manufacturing cannot succeed without the appropriate printing systems, of which there are up to three in the V1 production cell.

The printing systems impress with ultra-fast printing speeds, excellent surface quality and a wide variety of materials to enable a wide range of properties.

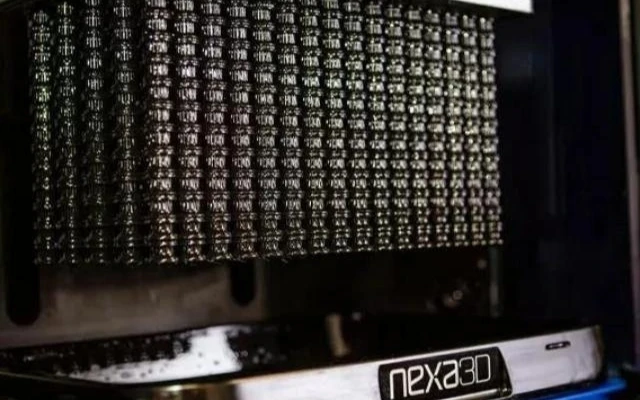

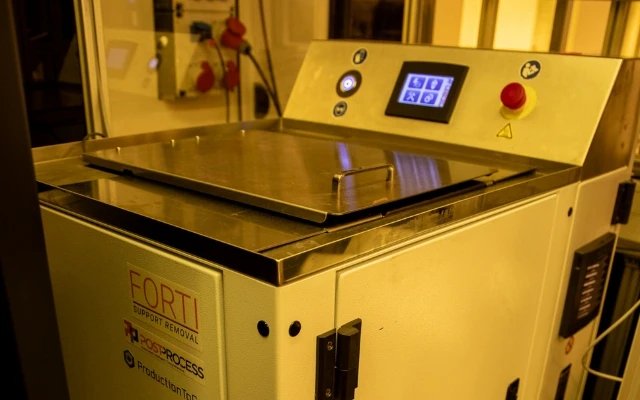

Two cleaning stations, one an SVC system and the other an ultrasonic water bath, ensure that even the most complex components are thoroughly cleaned.

The SVC solution is responsible for removing the excess resin, using a solvent specially formulated for resin components, while the water bath removes any possible residues of this solvent.

With two shelves facing each other, one of which is used as an input shelf and the other as a storage shelf, the V1 production cell offers enough space for the production of up to 36 building panels.

In addition, these two shelves are equipped with sensors that tell the robotic arm from which shelves it can remove empty building panels and into which it can place full building panels.

To ensure maximum safety for the entire process and for the workforce, both an air conditioning system and an extraction system are integrated into the V1 production cell.

This ensures that the temperature is always perfect for the printing process and the material, and that the toxic fumes that can arise during the printing process with resin are removed from the cell.

The production cell is surrounded by a stable Plexiglas wall, which separates it from the surrounding production and increases the safety of the users and the surrounding workforce.

This wall both keeps toxic vapors in the production cell, from which they are removed by the extraction system, and improves temperature control.

The digital model is prepared for printing using the appropriate CAD or 3D modeling software and then transferred to the printing system to begin the printing process.

Despite the exceptionally high degree of automation with the production cell, some aspects have to be prepared manually. However, this preparation only consists of inserting the empty building platforms into the input shelf, refilling the solvent for the cleaning station and placing material in the printer, although the filling is automated.

Now the robotic arm begins its work. It removes one of the building plates from the input tray, inserts it into the printer and a sensor in the printer registers the inserted building platform, whereupon the print job is automatically started. After the end of the printing process, the robotic arm automatically removes the building platform and feeds it to the next step.

After a brief stop on the re-gripping fixture, the print job is placed in the first wash station. During this wash process, which takes six minutes, resin residue is removed, after which the component is placed in the second wash station, an ultrasonic water bath, for another six minutes to remove potential residue of the previously used solvent.

Finally, the robotic arm places the print job in the storage rack, which can hold up to 36 building plates. The robotic arm then removes the next empty building platform from the input rack and the printing and washing process is repeated until the entire storage rack is full.

After the print cycle has been completed, the finished print jobs must be removed manually and placed in a post-curing station of your choice to achieve maximum mechanical properties. Then, only the support structures need to be removed and the component is ready.

Together we automate your production, reduce costs and increase your production output. Ideal for applications with short cycle times like CNC machines and 3D printer farms.

If you have a specific project, please contact us!

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy