3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

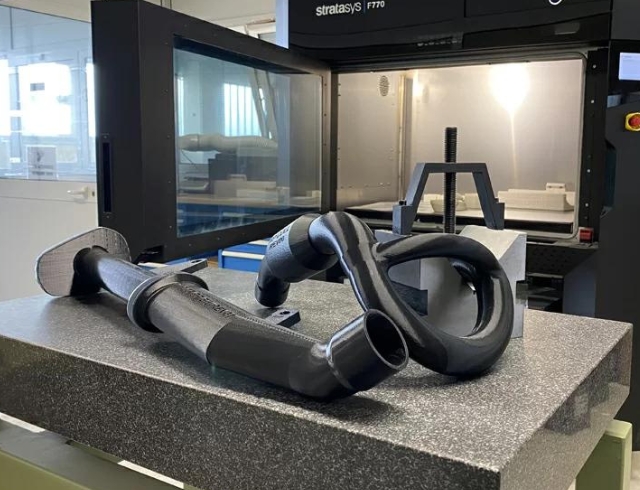

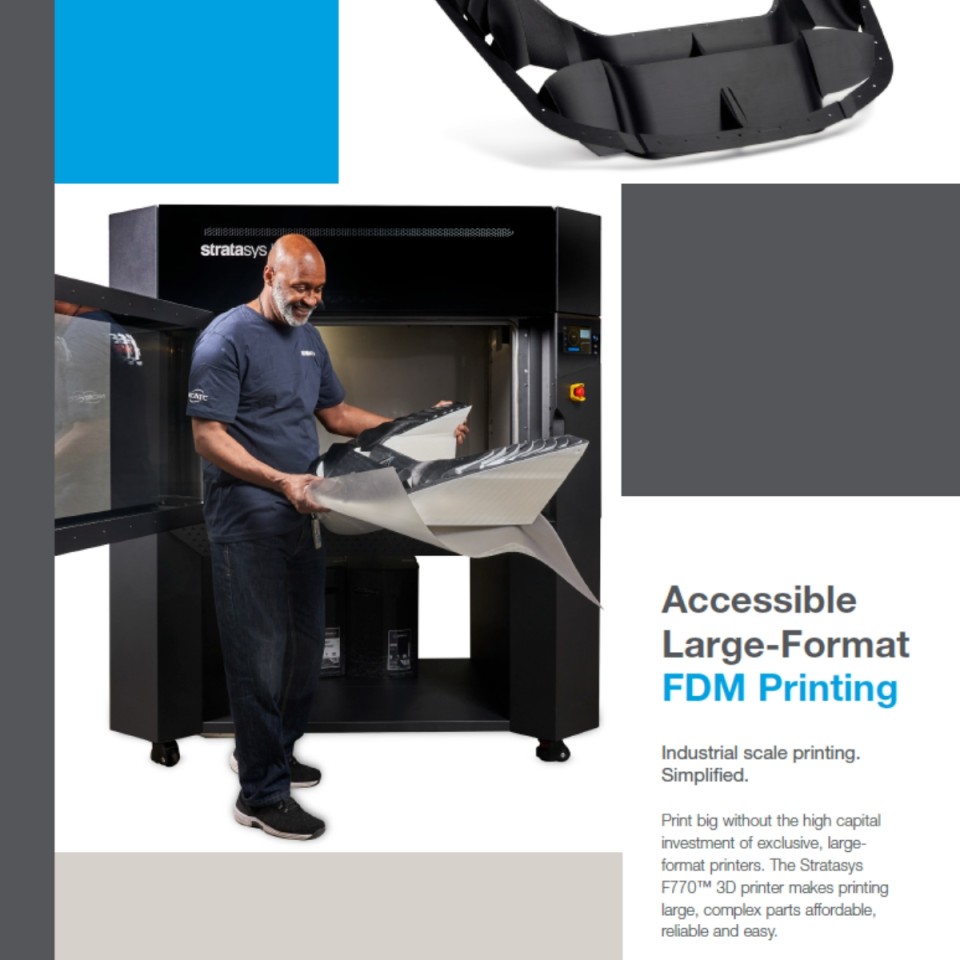

Produce intricate, functional components using FDM® technology on a large scale with less hassle than before. Possess the ability to consistently produce incredibly detailed geometries using a special soluble support.

Large-scale, dependable 3D printing is the main goal of the F770™. It is made specifically to accomplish that, and almost anyone can start the production and then return to their actual work. When paired with its reasonable pricing, it greatly increases accessibility to dependable large-format 3D printing and the time and money savings it offers.

Massive size 3D printers like the F770™ have the capacity to create massive parts and can handle challenging tasks. This printer has a build volume of 372 liters, which gives it ample space to print large production tools, prototypes, and final items.

Maximize your results and steer clear of the difficulties associated with printing huge pieces.

Technical Specifications:

Build Volume: 1000 x 610 x 610 mm

Maximum Length on diagonal: 1,171 mm

Layer Height: 0.178 / 0.254 / 0.330 mm

Material Delivery: 3,277 cm³ coil box

The F770™ has the longest fully controlled heated chamber in the market that can accommodate a build volume of 1000 x 610 x 610 mm and a maximum length of diagonal of 1,171 mm.

The F770™ comes with a single F123 print head and has adaptive slice height options. It has layer resolutions of 0.178mm, 0.254mm and 0.330mm that is able to produce fully dense parts with the best possible print quality.

Having printable soluble support with the F770™ enables detailed features and no design limitations. Orient parts for the greatest strength and finish without worrying about access areas for removal and shaping.

There's no need to keep an eye on the printer all the time when it's operating. 3,277 cm3 of filament are included in quick-change material canisters, allowing for up to 140 hours of unsupervised printing. The F770™'s integrated camera allows you to monitor print status remotely from your mobile device. GrabCAD Print™'s monitoring feature also allows you to view continuously updated static images of print status.

With the F770™, you may take advantage of Stratasys® FDM® reliability and widely utilized engineering-grade thermoplastic materials.The F770™ can hold 3,277 cm3 SR-30 soluble support, 7 colors of ASA, and 3,277 cm3 of ABS black.

The sophisticated 3D slicer software is available with the easy-to-use GrabCAD Print™ software. This lets you apply high-level geometrical modifications, improve details, and prioritize parts. You may readily get detailed views of your model, tray, and slice preview prior to sending parts to the printer. This guarantees effective printing of tools and large parts. Power users who wish to fine-tune their files for more control over printed part results can utilize the F770™'s Insight™ software and use MTConnect to connect the F770™ to a smart factory floor.

Call or email us and we will be happy to help you.

By using 3D printing to create or outsource manufacturing tools, you may cut costs and lead times. Because of the F770™'s enormous build volume, you can make larger tools all at once instead of splitting them into separate pieces that need bonding.

The huge capacity of the F770™ makes it possible to easily and internally prototype large items. Rather of using resized versions of your designs, print them out in their entirety. Design and production can proceed more quickly by validating concepts and fit more quickly.

For short-run end-use products that are too expensive to manufacture using CNC machining or other conventional manufacturing techniques, 3D printing is the ideal option. Either a few large products or a lot of smaller pieces, the F770™ is properly scaled to meet the demands of these low production quantities.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy