3D printers

High quality 3D printers

Simply fill out the form behind the button and receive a free sample of a technology of your choice!

3D printing with metal is the youngest type of 3D printing to date, but nevertheless has the most manufacturing methods. These can basically be divided into two categories. Firstly, the older laser or electron beam-based processes, which include Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), Laser Metal Deposition (LMD) and Electron Beam Melting (EBM), in which the raw material is melted together using a laser or electron beam.

The second category consists of sinter-based processes such as Metal Binder Jetting (MBJ), Cold Metal Fusion (CMF), Bound Metal Deposition (BMD) and Metal FFF printing (MFFF), in which the raw material is either bonded together using heat and binder or extruded, as in filament 3D printing, to create a green part and then transformed into a fully-fledged metal component in an external sintering furnace.

The raw material comes in different forms depending on the process. Either pure metal powder is used (SLM, DMLS & EBM), metal powder that is combined with a polymer binder (MBJ & CMF), metal-polymer rods (BMD) or metal-polymer filament (MFFF).

3D printing with metal is characterised by its unique design freedom, which enables even the most complex internal structures, an isotropic microstructure, fast printing speeds, a very high level of detail and very low reject rates, which protects both the environment and production costs.

In the LMD process, an existing component or metal base is heated with a laser, creating a molten pool. A metal wire is then deposited onto this, fusing with the molten pool to form a new, uniform layer.

This process achieves an extraordinary density of over 99.99%. It also has an excellent printing speed. However, it is less suitable for very delicate components and more suitable for large and simpler components.

With MBJ, a thin layer of metal powder is applied to the build plate and bonded in layers using a polymer binder. This binder is completely dissolved during debinding and sintering.

This method scores points for its exceptional precision and repeatability, among other things, but is a comparatively long process. It is therefore less suitable for one-off production, but all the more suitable for series production.

In the SLM process, as with the SLS process, the powder is selectively fused together using a laser, although unlike SLS printing, support structures are absolutely essential due to the higher weight of metal.

SLM boasts the ability to achieve different densities in the same component and a high level of accuracy, but is one of the slower metal 3D printing processes.

For CMF, SLS printers are used instead of metal printers. On these, a metal-polymer mixture is melted by laser at low temperatures and the polymer binder is dissolved during debinding and sintering.

By using SLS printers, CMF benefits from very low acquisition costs and is also a very safe process due to the low temperatures. However, the choice of alloys in this process is very limited.

The DMLS process is very similar to the SLM process, the difference being that in DMLS the laser does not melt the powder, but only sinter it.

As sintering requires less precise temperature control, DMLS provides a greater variety of alloys and is a simpler process. However, DMLS components can have microstructures or porosities, which limits the mechanical properties.

Like FFF 3D printing, BMD uses an extrusion process. However, instead of filaments, metal-polymer rods are used, which are heated and extruded in liquid form onto the build plate, where they harden again.

BMD enables metal parts to be produced without supports and is also suitable for small companies thanks to its low costs and office-friendly structure. However, it is less precise than other metal processes.

For the EBM process, the internal pressure in the chamber is reduced until a vacuum is reached and the build chamber is then heated. After this, a thin layer of conductive metal powder is applied, which is melted by an electron beam.

This beam can split and fuse several areas at the same time, which increases the speed. However, the beam is also wider, which reduces precision.

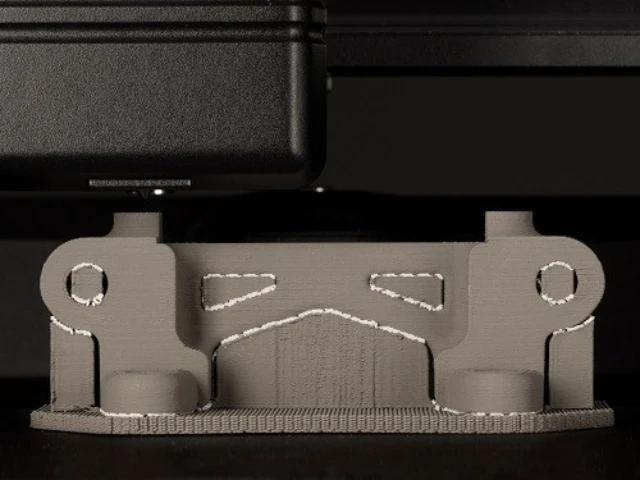

In MFFF printing, the FFF 3D printing process is mixed with metal, which comes in the form of a metal-polymer filament. The filament gets conventionally melted, extruded and made rigid again on the build plate.

MFFF printing is particularly known for its user-friendliness and ease of use for beginners, as well as its high printing speeds, although users have to make compromises in terms of component quality.

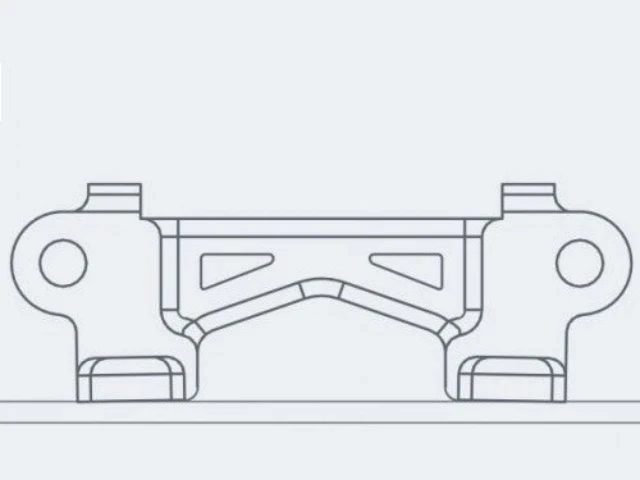

In the first step, the STL or CAD files are transferred to the software. Here, support structures are automatically generated and parameters based on geometry and material are transferred to the printer.

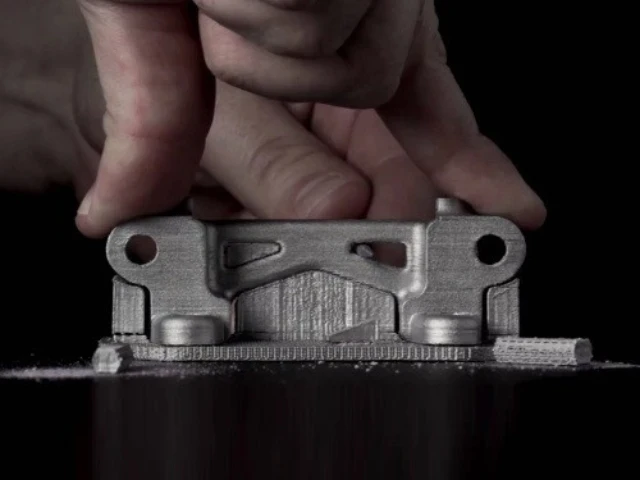

Depending on the production technology, either a finished metal component (laser-based process) or a green part (sinter-based process) is produced directly. In the case of the green part, this consists of metal and the polymer binder.

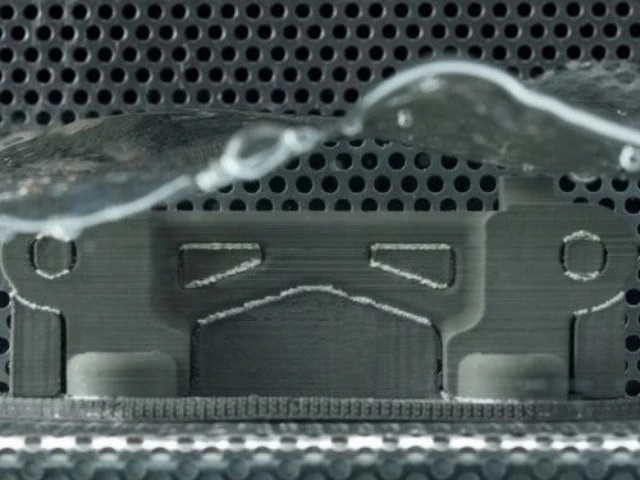

In the sinter-based processes, the primary binder is now removed from the green part with the help of debinding fluid. This creates an open-pored structure, which makes sintering easier.

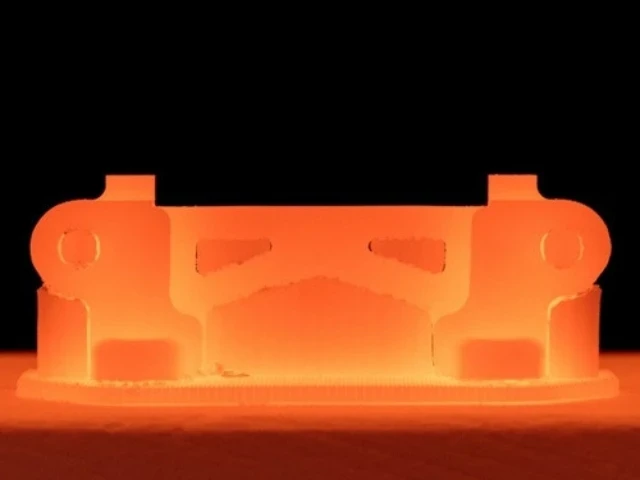

After debinding, the component is sintered at a specific temperature in sinter-based processes. This thermally dissolves the remaining binder and fuses the metal particles, resulting in a density of approx. 99.8 %.

Supports are essential for certain processes or geometries in order to maintain dimensional stability during printing. With sinter-based processes, removal can simply be done by hand, while laser-based processes usually require the use of tools.

After the components have been finished, they have a hardness of approx. 250 to 280 HB and can be further processed like a normal semi-finished product, e.g. with heat treatment to further increase the hardness.

Thanks to topology optimisation and the associated weight reduction, metal 3D printing is a perfect alternative to conventional manufacturing methods in the aerospace industry. Possible components include engine components, structural elements, fuel nozzles and turbine blades.

With several tool steels to choose from, such as D2 or H13, high-strength, temperature-resistant and durable tools can be produced on-demand using metal 3D printing. Possible components include injection moulding tools, moulds, cutting and punching tools as well as customised tools.

Thanks to its optimised weight, fast on-demand production and high level of detail, 3D printing with metal is one of the most important tools for climate-neutral individual transport in the automotive industry. Possible components include brake discs, body parts, engine mounts and prototypes.

For metal consumer goods, additive manufacturing has become popular with many companies due to its excellent production speed and the ability to make quick adjustments. Possible components include jewellery, watches, electronics and sports equipment.

Fast and patient-specific treatment is naturally a priority in medical technology, which is why metal 3D printing has now also made its mark here. Possible components include implants, surgical instruments, prostheses and prototyping for medical devices.

Educational institutions, especially in STEM subjects, benefit from metal 3D printing through more realistic training and the opportunity to introduce students to the future of production with their own hands. Possible components include prototypes, artefacts, engineering parts and architectural models.

Our team of experts supports you in the selection of materials and finds the suitable process with the optimum hardware solution for the application.

We will be happy to advise you on which material and which manufacturing process is suitable for your application. Depending on the process, materials such as stainless steel, copper, titanium, carbide, Inconel and all Ni-based alloys can be processed.