3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

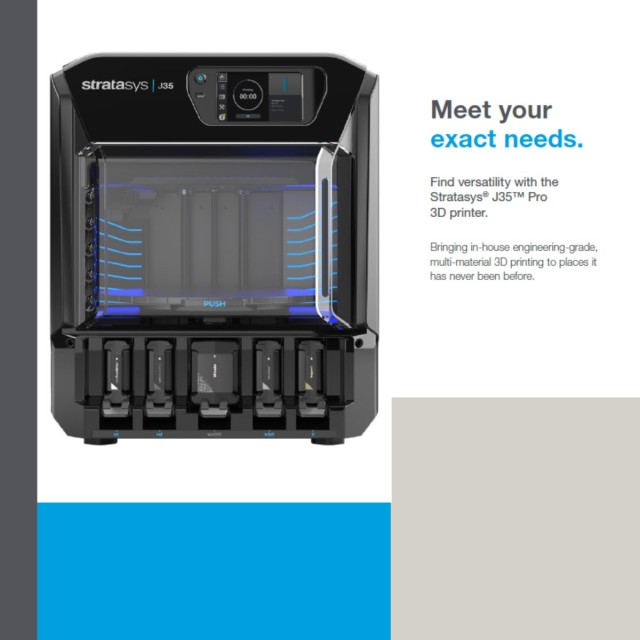

The J35™ Pro is a low-cost PolyJet™ 3D printing system ideal for shared office environments. It offers grayscale multi-material capabilities for functional design and concept modelling, as well as cutting-edge print capabilities.

Based on the J55™ Prime the Stratasys® J35™ Pro 3D Printer is a compact, office-friendly printer that combines the technology of the larger Stratasys® PolyJet™ printers in a smaller form factor.

Excellent surface quality is achieved by the multi-material printer with three material channels, which has a rotating build platform and a fixed print head. Its tiny footprint and ProAero™ filter technology for odour-free, quiet, and energy-saving operation make it ideal for use in an office or design studio.

Powered by GrabCAD Print™, you can optimise your design-to-print process with ease. Seamlessly import your designs in 3MF or native CAD file formats, and manage your print tasks remotely using the comprehensive monitoring capabilities. Produce complex pieces without compromising on detail or precision, thanks to the support for waterjet printing.

Technical Specifications:

Build Tray Size: Round print tray with up to 1,174 cm²

Print Height: 158 mm

Maximum Model Height: 155 mm

The J35™ Pro's Programmable PhotoPolymerization (P3) technology carefully regulates the forces, temperature, and light during the printing process. It can produce parts with remarkable detail, accuracy, and surface quality that rival those made by traditional injection moulding thanks to its high degree of precision and control.

The Stratasys® J35™ Pro 3D printer delivers advanced multi-material capabilities that empower you to create a diverse range of functional prototypes, concept models, and end-use parts. The J35™ Pro takes multi-material 3D printing to the next level by enabling you to combine up to three different materials in a single print. This streamlined approach allows you to produce digital material compound parts, assembly-ready components, or individual parts with distinct properties - all on the same build tray.

The J35™ Pro features a unique rotating build tray and soluble support removal, which simplifies post-processing and enables the creation of complex parts without compromising accuracy or detail.

The J35™ Pro supports a wide selection of PolyJet photopolymer materials, including rubber-like, high-impact, rigid, translucent, and even biocompatible options. This material versatility allows you to precisely match the properties of your printed parts to your specific design requirements.

The Stratasys® J35™ Pro 3D printer features the innovative ProAero™ filtration system, which enhances the printer's performance and user experience in an office environment. The ProAero™ filtration system is designed to capture any particles, fumes, or odours generated during the 3D printing process. This ensures a completely odour-free working environment, making the J35™ Pro suitable for shared office spaces. In addition to odour control, the ProAero™ technology also provides silent operation and low power consumption, further improving the printer's integration into an office setting.

The Stratasys® J35™ Pro 3D printer offers a simplified, streamlined workflow powered by GrabCAD Print™ to optimise the design-to-print process. Import your designs using native CAD file formats or the industry-standard 3MF file format. In addition to the GrabCAD Print™ software, the J35™ Pro provides access to a full ecosystem of workflow tools to streamline the design process. This includes cloud-based services, print-to-click (Keyshot) functionality, on-demand training, and an online community.

Call or email us and we will be happy to help you.

The high-quality output and multi-material printing capabilities of the J35™ Pro enable the construction of models that are virtually indistinguishable from the final product. This is especially useful in sectors like consumer electronics, automobiles, and aerospace, where a product's visual attractiveness and user experience play a crucial role.

Instead of depending on more expensive and time-consuming traditional manufacturing processes, producers can create unique jigs, fixtures, and tools as needed by utilising the capabilities of the J35™ Pro. The versatility of design that 3D printing provides also makes it possible to create ergonomic, user-friendly tool designs that can increase productivity and lessen worker strain.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy