3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

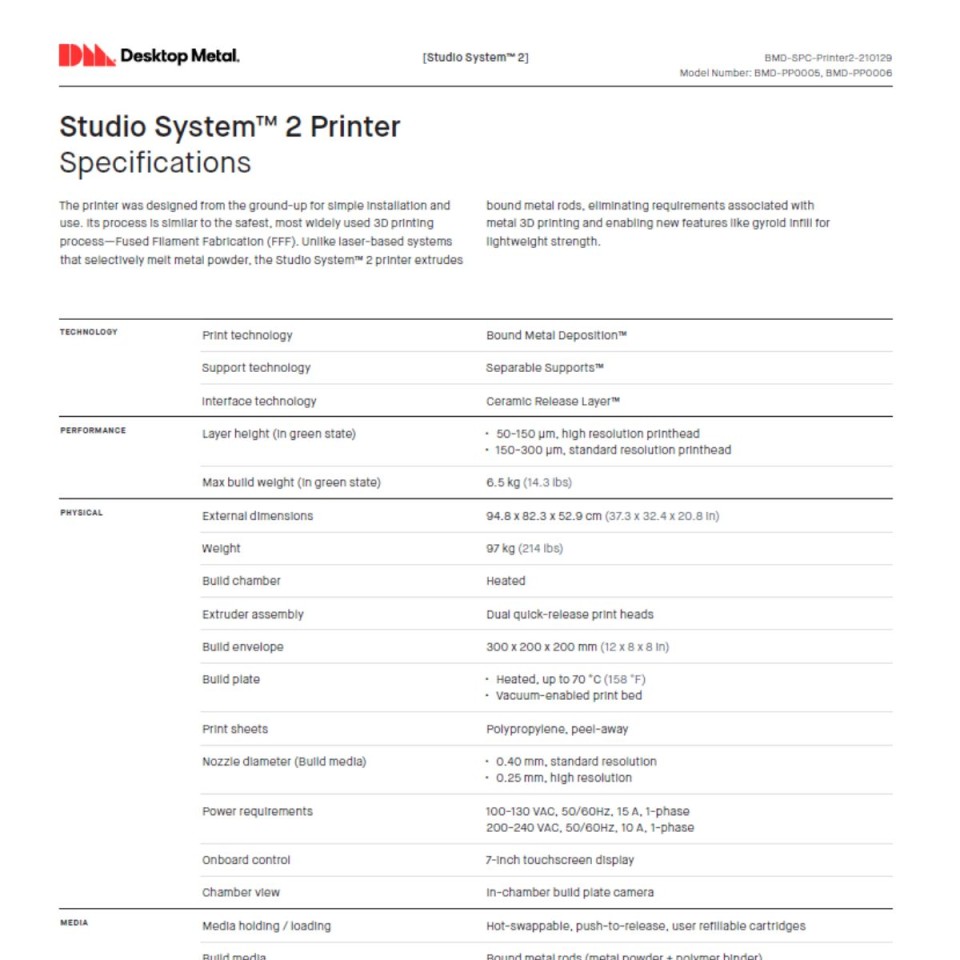

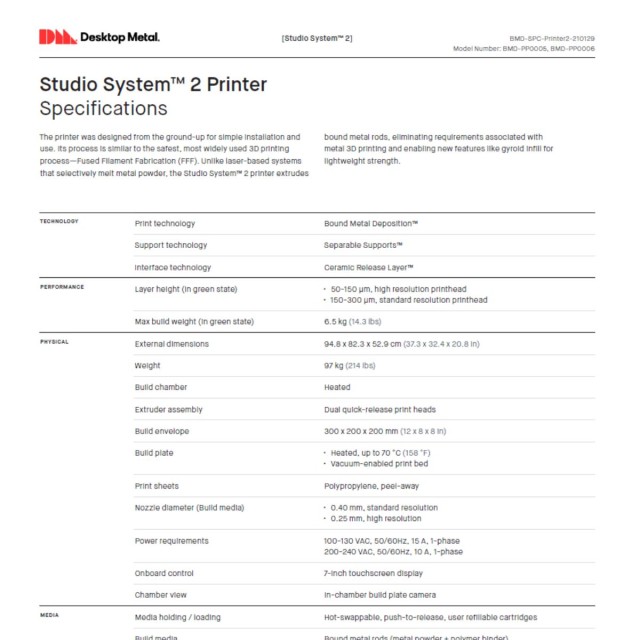

The Studio System™ 2 from Desktop Metal®, utilizes extrusion-based printing technology and combines fused filament fabrication (FFF) technology with metal injection molding (MIM) through the downstream sintering process.

Studio System™ or Studio System™ + can be upgraded without further ado. Only minor hardware adjustments to the printer and oven are required to support the new material system.

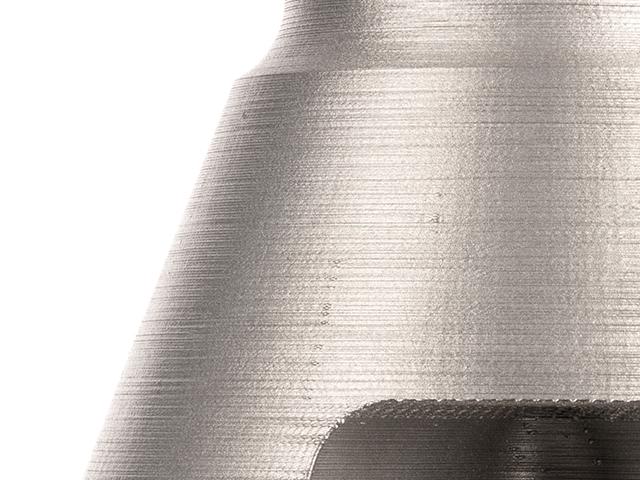

The StudioSystem™ 2 eliminates the need for debinding with solvents by using a new material system, thus enabling a higher degree of automation (two-stage process). In addition, the new material composition achieves an improved surface finish on the side walls of the components but also on highly complex component geometries.

You don't have to be a metal expert to print complex parts.

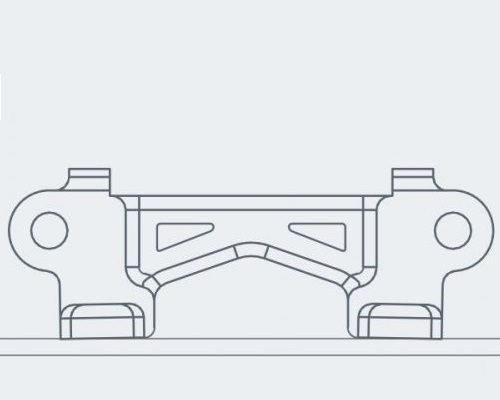

Fabricate software automates all aspects of part creation - from printing to sintering. The software compensates for shrinkage, independently calculates the necessary support structures and generates the machine code.

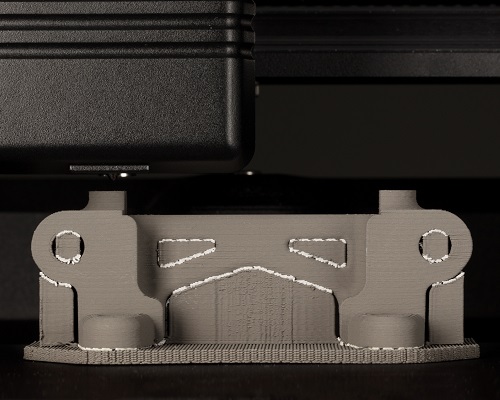

The Studio System™ 2 features the second generation of "Separable Supports" support structure technology. A newly developed ceramic mixture is inserted into the interfaces between the component and the support structure via a second nozzle so that the supports can be easily removed by hand.

Thanks to the user-friendly technology of Studio System™ 2, you can invest more time in development/design and avoid long setup times.

Designed to deliver outstanding parts with excellent surface finish, the Studio System™ 2 now enables users to achieve impressive results right from the start.

This has been achieved through a completely redesigned material platform, updated support technology and new print profiles.

Optimally matched pressure profiles and material-specific sintering curves achieve material properties that meet or even exceed MPIF standards. The components achieve densities of up to 98 percent - similar to castings.

With the Studio System™ 2, you can customize components exactly to your needs. The free choice of print parameters allows a wide range of setting options. Starting with wall thicknesses of up to 5.25 mm or fine structures with a high-resolution print head (250 µm).

Using metal powder from the metal injection molding (MIM) industry, the printing material is pressed into bonded rods. The rods contain metal powder mixed with wax and polymer binders. Compared to metal filaments, the rods have a higher ratio of metal to binder, resulting in lower shrinkage and higher stability during sintering.

Push-to-release material cassettes can be changed during printing without interrupting printing. This allows users to use every gram of material without having to stop a print to change a spool.

Thanks to the exchangeable material cassettes, print heads and nozzle brushes, you can change from one material to the next within minutes without having to clean the system at great expense. Material changeover is user-friendly and safe. No protective clothing needs to be worn.

The secure, web-based software Fabricate (stand alone also possible), creates the so-called machine code from STL files and automatically generates the appropriate parameters and necessary support structures based on the part geometry and material.

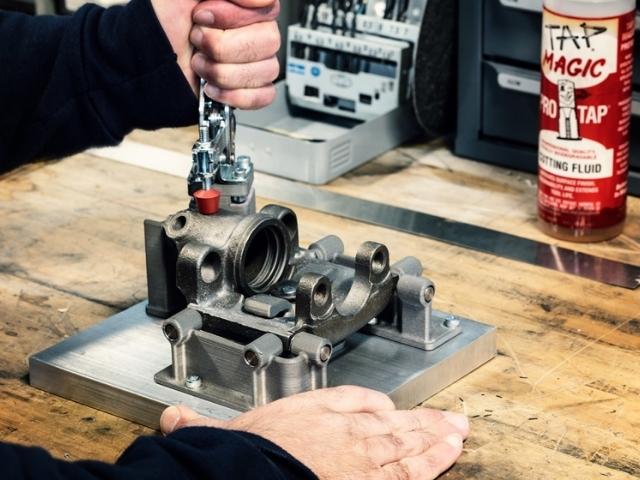

Polymer-bound metal powder is extruded from the metal rods, printing the green compact layer by layer. The process is called "Bound Metal Deposition.

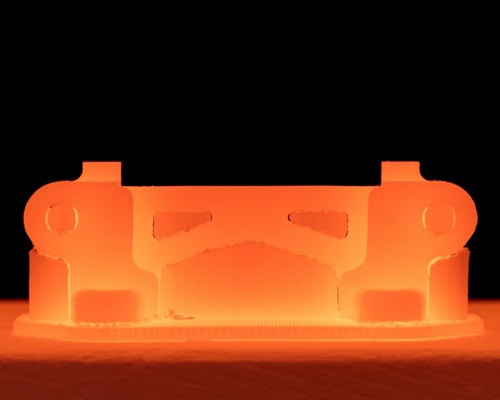

The green compact is placed in the sintering furnace and heated to the material-specific temperature. During this process, the binder burns and the metal particles fuse together. The finished metal part then has a density of approx. 96-99.8%.

Call or email us and we will be happy to help you.

Functional Prototyping

Metal 3D printing enables the rapid production of functional prototypes and is a time-efficient/cost-effective manufacturing process to quickly map iteration loops before the so-called "design freeze" occurs.

Field models made of 3D-printed plastic are becoming less and less important, as they often do not meet the required mechanical and thermal properties.

Fixtures and fittings are often required in small quantities and often have a complex geometry. To meet rigidity and strength requirements, individual components are usually made of metal. Because frequent use leads to wear, the ability to quickly manufacture replacement parts is critical to operational efficiency.

Customer-specific mold applications often require parts with complicated geometries that are difficult or impossible to produce using conventional manufacturing processes. One example of this is mold cavity inserts with integrated cooling channels, which shorten the cycle times of injection molds and increase the quality of the molded product.

The Studio System™ 2 enables the rapid production of complex small batches and brings the benefits of additive manufacturing directly to the workbench. This eliminates the need for expensive molds and mold inserts.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy