3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The ultimate production 3D printer for manufacturing, capable of printing the broadest range of engineering-grade materials, with the highest accuracy and precision, engineered for durability, repeatability, and reliability in demanding manufacturing applications. It also boasts the largest build platform, maximum throughput, and repeatability.

To accomplish true 3D printing manufacturing, rely on the F900™. The reliable results required to fulfil production demand are provided by its huge construction volume and verified precision. You may cover a wide range of applications with a varied material selection, from high-performance polymers to engineering and industrial-grade thermoplastics.

Stratasys® F900™ is the most advanced and accurate FDM® system on the market. Designed to meet the most exacting manufacturing requirements, the Stratasys® F900™ boasts the greatest build size of any Fortus® system. Unmatched precision, consistency, and predictability are provided by the control software, which also makes excellent use of the system's technology to increase throughput and reliability.

The Stratasys® F900™, equipped with a built-in camera, GrabCAD Print™ software, Insight™ software, and MTConnect, streamlines workflow and facilitates easier job monitoring.

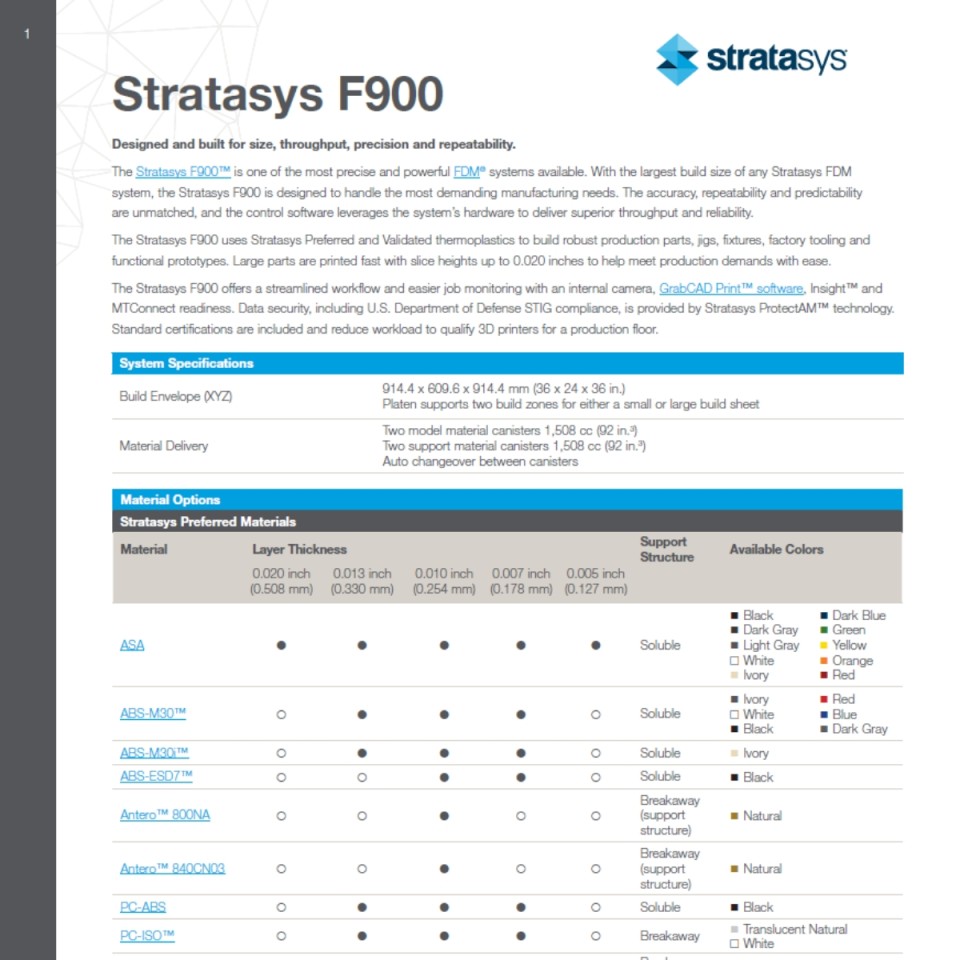

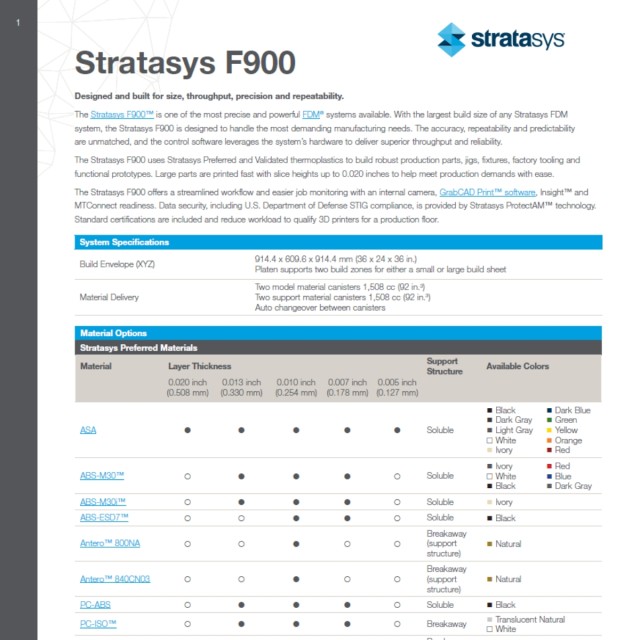

Technical Specifications:

Build Volume: 914.4 x 609.6 x 914.4 mm

Layer Height: 0.127 / 0.178 / 0.254 / 0.330 / 0.508 mm

Material Delivery: 3,277 cm³ coil box

When compared to in-plane (XZ) performance, parts produced on the F900™ show over 80% greater strength in the vertical (ZX) plane for specific materials. This allows you to get more uniform mechanical qualities across the component while having more flexibility in how you orient the part in the build chamber for the best print results.

When it comes to part attributes, the F900™ offers unparalleled consistency. Experiments on the ultimate tensile strength of ASA material show a variation of less than 6% over several F900™s in every part of the build platform. You receive reliable, consistent results from the very beginning to the very end.

In addition to having a vast array of applications ranging from standard to industry certified, the F900™ is faster and more accurate. The F770™ was created to offer a less expensive method of producing precise big prints on specific materials.

The F900™ can print over 25 Stratasys® preferred and validated Materials, 14 industrial-grade materials, breakaway supports and a soluble support and is currently the only FDM® printer in the market able to make parts for commercial airlines. Print materials such as ABS-M30, ABS-30i, ABS-ESD7, FDM® Nylon 6, FDM® Nylon 12, FDM® Nylon 12CF, Antero 800NA, ASA, PPSF, PC, PC-ABS, ST-130, ULTEM™ 9085 resin and ULTEM™ 1010 resin.

The F900™ has live data analytics, is MTConnect-ready, has a wide range of print resolutions and has accessible, informative and easy-to-read job reports.

The F900™ utilises Stratasys® ProtectAM™ technology to offer a range of secure connectivity solutions, including STIG compliance that meets DOD regulations. It comes with a dew point monitor and a powerful airflow dryer for moisture management and an internal camera for production monitoring.

The sophisticated 3D slicer software is available with the easy-to-use GrabCAD Print™ software. This lets you apply high-level geometrical modifications, improve details, and prioritize parts. You may readily get detailed views of your model, tray, and slice preview prior to sending parts to the printer. This guarantees effective printing of tools and large parts. Power users who wish to fine-tune their files for more control over printed part results can utilize the F900™'s Insight software and use MTConnect to connect the F900™ to a smart factory floor.

Call or email us and we will be happy to help you.

Use the F900™'s enormous build volume to prototype big parts in a single print, saving money and time by doing away with the need for traditional prototyping techniques and their related lead times. Proprietary and functional prototypes are made possible by an extensive selection of materials.

Swap out bulky, metal fixtures, jigs, and manufacturing aids for lighter instruments composed of robust, long-lasting thermoplastics. To reduce production downtime caused by broken tools or to validate new production tooling fast, the F900™ can swiftly generate large tooling fixtures.

Utilize 3D printed end-use parts for obsolete, low-volume orders, or as a stopgap until full production to meet production targets more quickly. Large batches of tiny or large components that can be created in a single piece can be accommodated by the F900™'s enormous build volume 3D printer capability, which unifies multi-part assemblies.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy