3D printers

High quality 3D printers

HealthcareToGo Dental Innovations Tour 2025 - North Germany

Secure your seat

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send EmailBefore an object can be produced with a 3D printer, the object must be digitally created as a model, for which one or more 3D modeling software is used. When we talk about 3D modeling software, we usually mean CAD software.

However, this is by no means the only type of software that can be used for 3D printing. Other types of software include simulation and optimization software, repair software, slicer software, and many more.

In industrial 3D printing, software is playing an increasingly essential role in automating workflows and reducing the workload on employees. To reduce effort, all-in-one software solutions are often used, which contain all the tools needed to use the 3D printer.

3D Modeling Software is used to create, edit and optimize digital 3D models, which are later sent to the printer as STL or OBJ files to start the printing process.

In most cases, CAD software is used in 3D printing, enabling precise technical designs. However, mesh-based or parametric modeling software can also be used.

3D Scanners are frequently used in the production of spare parts, in particular, to create perfect digital models of existing components. However, these scanners are relatively expensive and difficult to use.

3D Scanning Software, which offers a cheaper alternative to 3D Scanners, can help. These days, there are even scanners of this kind for smartphones, which can be used to quickly and easily turn objects into digital models.

An entire industry has emerged around the digital simulation and optimization of components in their functional environments. Whether FEM, CFD, or topology optimization, components and manufacturing processes can be simulated and optimized using the digital twin.

On one hand, such software minimizes production costs by reducing material consumption, while also achieving weight optimization while maintaining mechanical strength.

Repair Software is an important tool within the printing process, as it can fix potential defects on the digital model that were previously detected by the simulation software.

By using such software, potential defects on the digital model can be quickly and, in most cases, automatically repaired, thus avoiding misprints and long source-of-error searches.

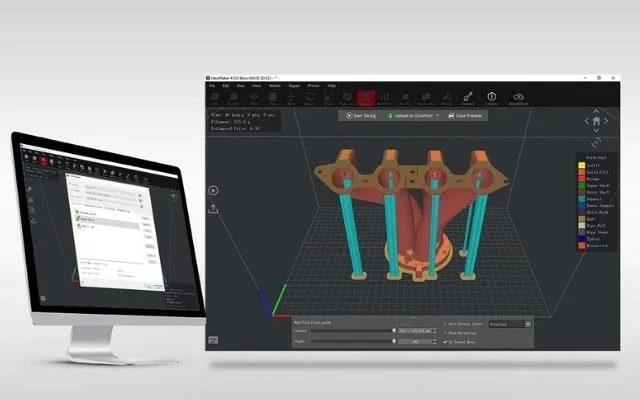

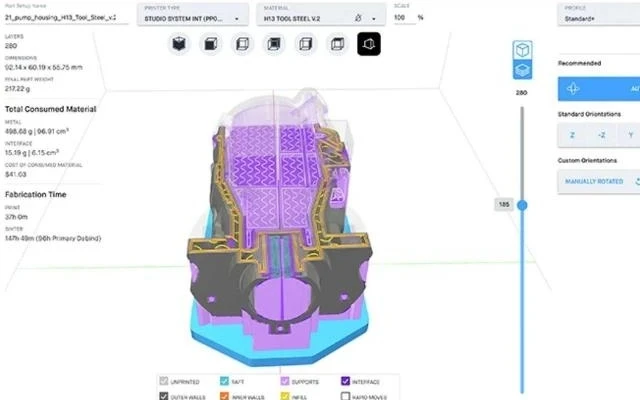

Slicer Software is the final step from the digital model to the start of the printing process, in which the complete digital model is divided into thin layers that correspond to the layers of material ejected by the printer.

Finally, the instructions and the digital model that has been divided into layers are transferred to the respective 3D printer, which can then start the printing process.

Management Software is particularly indispensable for companies with large production volumes that produce numerous print jobs and have a large number of printers.

This software can be used to remotely monitor and control the entire printer fleet from a centralized location and to assign various print jobs to it, thus meeting an industrial scale.

Our team of experts will help you decide which software will meet your needs.

We will be happy to advise you on which software is easier to use, offers more features and is more reliable in each individual case.

If you have any questions, please feel free to contact us.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy