3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

Nexa3D® is a US company headquartered in Ventura, California. Just a few years after its foundation, the young company was already making waves in the 3D printing industry with the market launch of its patented LSPc® technology. Since then, it has steadily expanded its footprint with a variety of innovations.

When it was founded in 2016, it was already clear to Nexa3D® that success was directly linked to the expertise of its employees. Avi Reichental, CEO of 3D Systems® from 2003 to 2015 and one of the leading minds behind the founding of Nexa3D®, therefore quickly built a team of versatile and passionate 3D printing technicians, engineers and users to quickly make a lasting impression on the 3D printing industry.

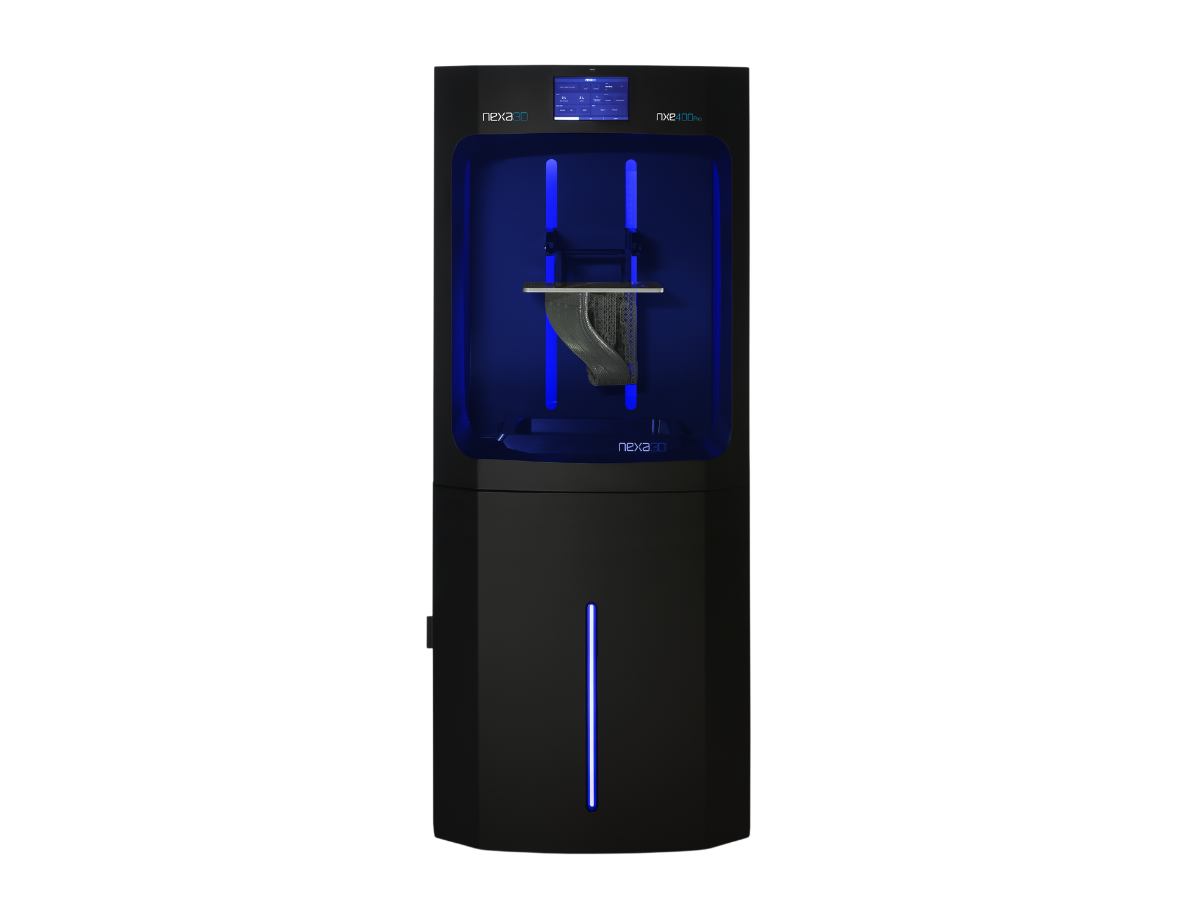

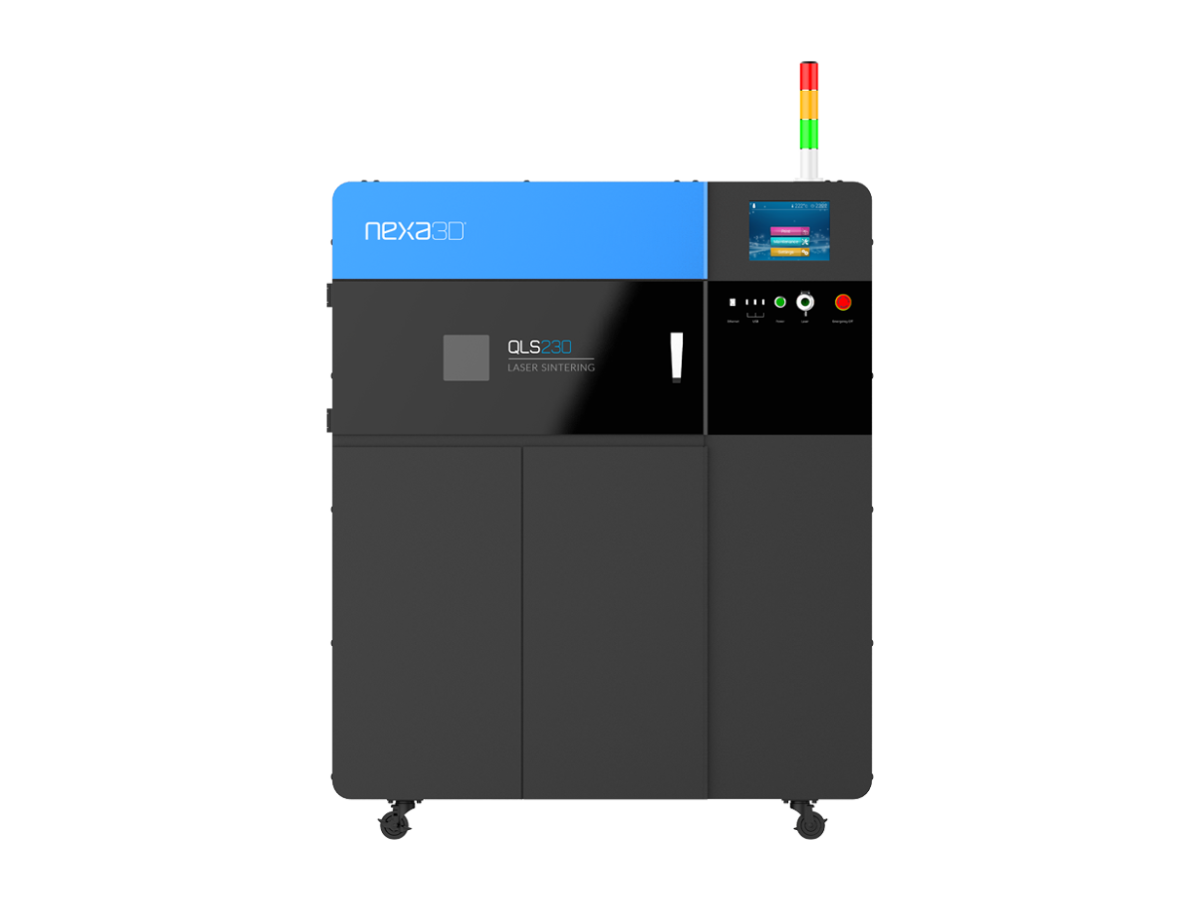

This strategy was undoubtedly going to work. Just four years after its foundation, Nexa3D® presented its first 3D printer, the NXE 400, which, thanks to the revolutionary LSPc® technology, immediately became a bestseller. In the years that followed, Nexa3D® continued to improve the LSPc-® technology, introduced new printers with this technology and also entered the market for powder-based printing technologies with its QLS series.

Nexa3D® is one of our most versatile suppliers. With their LSPc® printers and their ultra-fast printing speed, they have found particular favor in rapid prototyping, but also in the dental industry. The QLS series, on the other hand, is specifically designed for series production and has thus been able to shine in high-performance industries such as the automotive and aerospace industries.

The outstanding Nexa3D® printing systems are complemented by a wide range of material partnerships. This means that Nexa3D® systems can process materials from Henkel, BASF and Keystone, among others, enabling extraordinary properties to be achieved for countless applications.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy