3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

The Fortus® 450mc is designed for efficient production. The FDM® 3D printer offers a multi-application manufacturing solution that speeds up time to market by cutting design and build times, streamlining manufacturing processes, lowering overall costs, and encouraging innovation in the factory.

For applications requiring precise prototypes, robust manufacturing tools, or on-demand final components, the Fortus® 450mc is up to the task. In any sector, it provides the materials required to meet the rigorous manufacturing applications. The Fortus® 450mc is an additive manufacturing multi-tool that features soft jaw tooling and space components that can withstand electrostatic discharge.

Learn about the benefits of industrial FDM® additive manufacturing in terms of speed, cost, and material. With the precise, dependable performance of the Fortus® 450mc 3D Printer, you can streamline supply chains, quicken production, and cut expenses.

The oil and gas, aerospace, automotive, manufacturing, railway, and defence industries trust the Fortus® 450mc.

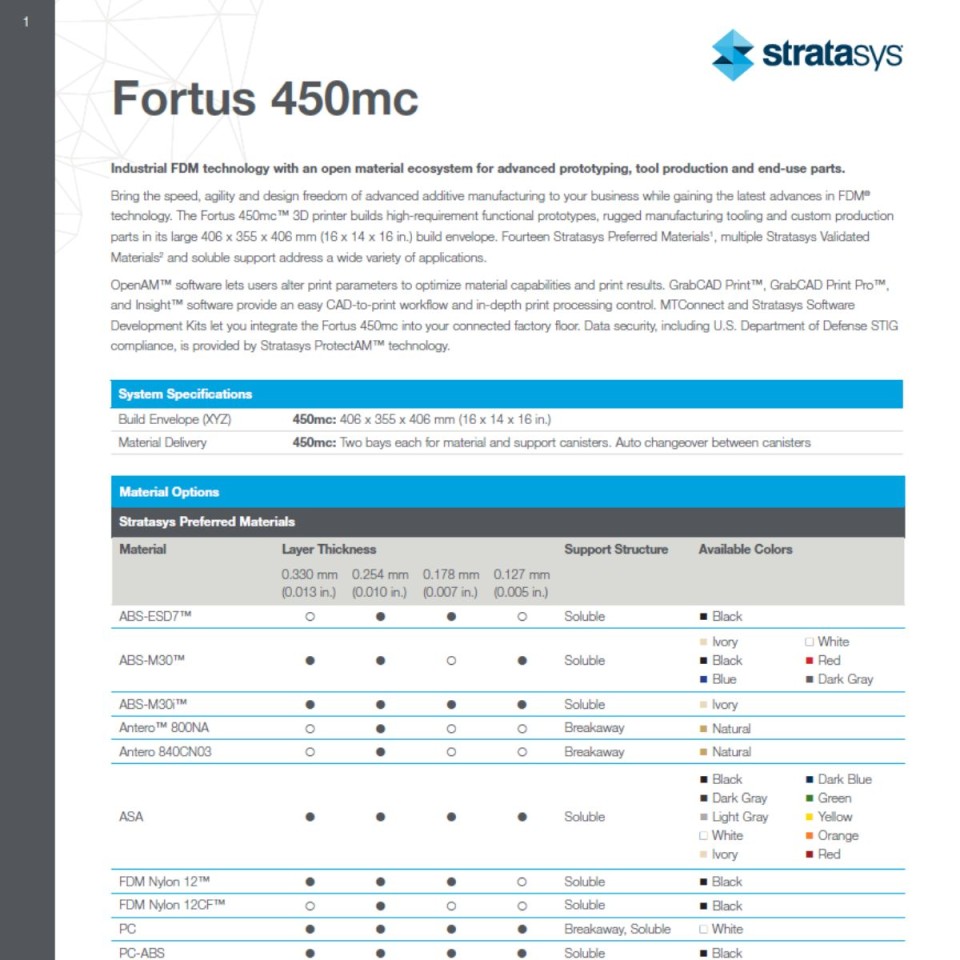

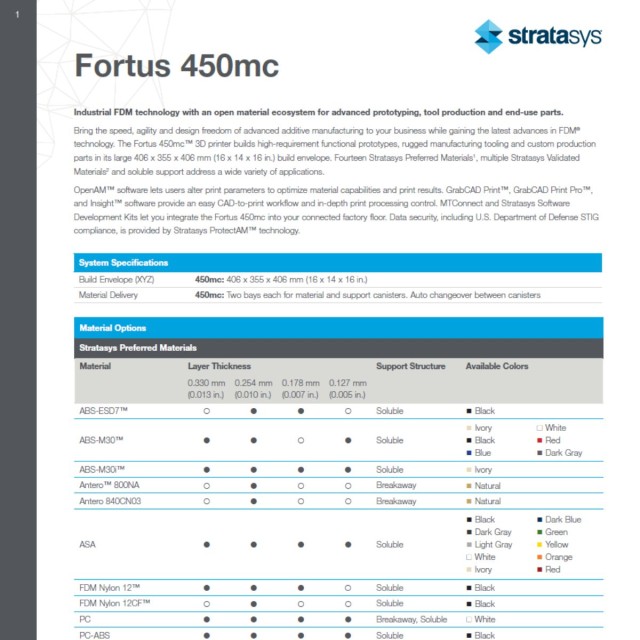

Technical Specifications:

Build Volume: 406 x 355 x 406 mm

Layer Height: 0.127 / 0.178 / 0.254 / 0.330 mm

Material Delivery: 92.3ci / 184ci / 500ci coil box

With a build capacity of 406 x 355 x 406 mm and a fully heated chamber, the Fortus® 450mc can provide the greatest print quality possible, even when using high-temperature materials.

When it comes to part properties, the Fortus® 450mc offers unparalleled consistency. Tests on the ultimate tensile strength of ASA material show a variation of less than 6% across all parts of the build platform and across different Fortus® 450mc printers. You receive maximum yield along with repeatable, reliable outcomes with a 93% print success rate.

For certain materials, the strength of the Fortus® 450mc components is greater than 80% in the vertical (ZX) plane as opposed to the in-plane (XZ) performance. This allows you to get more consistent mechanical qualities across the component while having more flexibility in how you orient the part in the build chamber for the best print results.

With an onboard compressor on the Fortus® 450mc, there is no need for shop air or an external compressor. Its small footprint and wheels allows for quick placement and startup.

Over 23 SSYS preferred and/or validated materials and a number of open materials can be printed on the Fortus® 450mc. Print materials such as standard plastics, engineering plastics (e.g. sustainable, ESD, food contact or medical grade), reinforced and specialty plastics (e.g. composites, fire resistant, wear resistant, has EMI shielding) and high performance plastics (high temperature FST). Support materials can come in breakaway and soluble formats.

For short or long unattended run times the Fortus® 450mc can accommodate 3 spool sizes. The spool sizes range from 92.3ci, 184ci or 500ci. It comes with two bays each for material and support canisters and it has auto changeover between canisters.

The task processing and management tools Insight and Control Center™ are included with the Fortus® 450mc system. For use with job reports, scheduling, and remote monitoring the system is compatible with GrabCAD Print™ and GrabCAD Print™ Pro. To add, it is possible to obtain OpenAM software by obtaining an Open Material License.

The Fortus® 450mc utilises Stratasys® ProtectAM™ technology to offer a range of secure connectivity solutions that reduces vulnerability to cyber threats, including STIG compliance that meets DOD regulations powered by Red Hat® Enterprise Linux® software.

Call or email us and we will be happy to help you.

Avoid the lengthy lead time and expensive expense of traditional prototyping. Use durable polymer-based 3D printed functional prototypes to speed up product development. Among the robust materials that are readily available for quick prototyping to validate your design are carbon fiber, polycarbonate, PEI, and PEKK.

By using 3D printed workholding tools, you may free up CNC capacity and cut down on setup time for CNC machines by up to 80%. The carbon fiber material and design freedom of the Fortus® 450mc enable you to produce workholding tools more quickly and at a lower cost. In addition to saving time and money, alternative 3D printed jigs and fixtures have the advantages of being lighter and more ergonomic than machined metal tooling.

The Fortus® 450mc is the ideal on-demand solution for cost-effective manufacture of low-volume and bridge-to-production parts. Tool-less 3D printing means parts can be produced much faster and for lower cost, bypassing the traditional supply chain.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy