3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

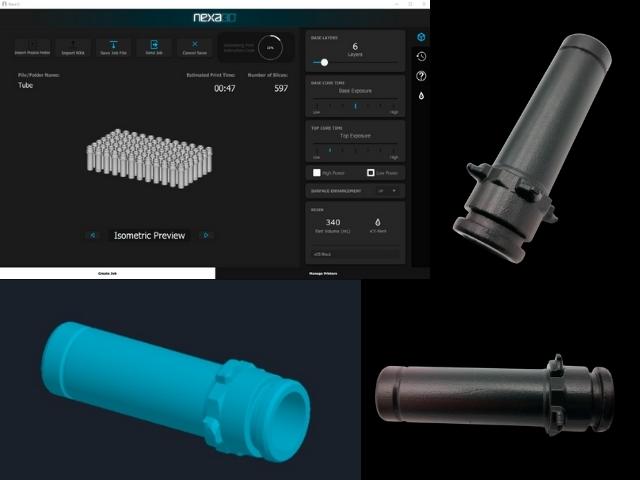

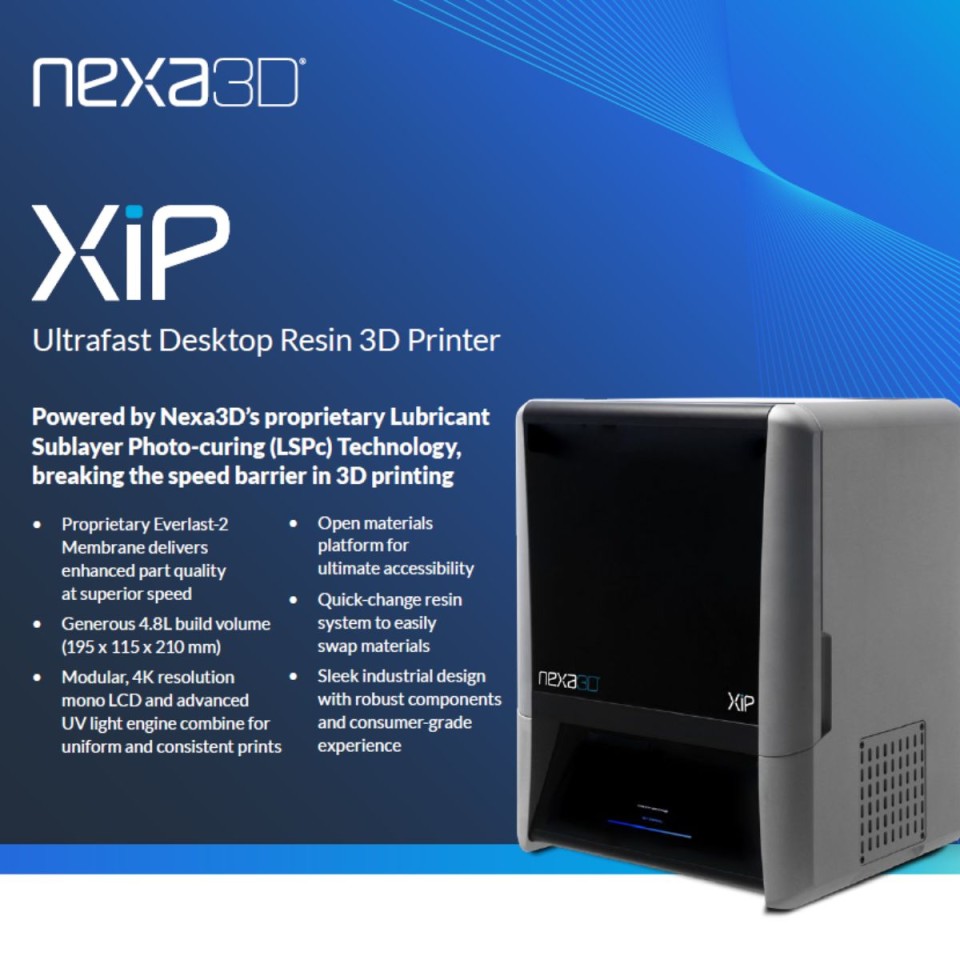

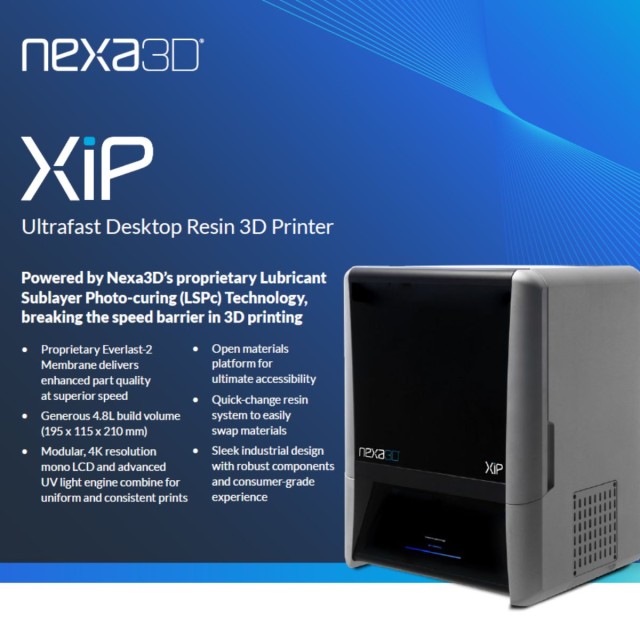

It breaks the record for fastest 3D printing with Nexa3D®'s patented LSPc® (Lubricant Sublayer Photo-curing) technology.

The Nexa3D® XiP is an ultra-fast desktop resin 3D printer with a build capacity of 4.8L and a small, compact footprint. The Nexa3D® XiP mSLA 3D printer is compatible with a wide range of general-purpose and elastomeric materials thanks to an open material platform that provides flexibility and easy material access.

With a wide range of materials and high productivity, the Nexa3D printer is ideal for virtually any application. Whether prototyping, volume production or dental, Nexa3D® XiP is the perfect 3D printer to print high-resolution parts in the shortest time possible.

Technical data:

Print volume: 4.8 liters

Build volume: 195 x 115 x 210 mm

Technology: 4K Monochrome 9.3" LCD

Pixel size: 52 µm

The aluminum housing anchors the components and Z-axis in place, providing a strong foundation that allows you to print with unprecedented speed and accuracy. A stable platform ensures that no extraneous movement will interfere with your printing. This allows for 20x the productivity!

Nexa3D® Everlast Membrane with increased life to up to 50,000 layers significantly improves part surface quality. With NFC® technology, your tank automatically tracks the life of its membrane as well as the type of resin currently used in it. Once you have moved the tank into position, it locks automatically and is ready for immediate use.

The resin cartridge allows the user to load a new material cartridge in an instant, even during a live print job. Once loaded, the printer automatically begins resin authentication and compatibility checks with the current manufactured parts.

With the new Gravity Feed Resin System, you can print large prints (up to 1.3 kg) without interruption. The dispensing system automatically fills the photopolymer in the tank and maintains a constant level.

Single lever design allows insertion and removal of build plate with a single hand. Flow dynamic design reduces surface area and accelerates resin flow back to the tank. Innovative design allows for quick draining and easy removal of parts.

The Nexa3D® XiP design is highly modular. Almost all wear parts can be replaced without tools. This makes servicing and maintaining these parts as easy as using the desktop 3D printer. Replace key components at the end of their useful life and simply install the upgrade to the new module yourself!

With the level sensor and NFC® devices, you can start a print job and know that there is enough resin for the entire print job. The printer tracks the level of resin in the material cartridge and automatically starts printing when it reaches the required level.

Nexa3D® XiP minimizes moving parts and is designed for continuous use. The only elements that move during printing are the Z-axis and the gravity fed flowing resin. The minimal number of moving parts extend the overall life of the 3D printer!

Analyze parts for the ideal printing process and use the material selector and build simulator to identify key geometries, important material properties, and areas for cost reduction.

Use LSPc® technology (Lubricant Sublayer Photo-curing) and print your part in a flash with the Nexa3D® XiP.

To wash out the excess resin, the parts must be washed with either the Nexa3D® Wash+Cure or another wash station.

The advanced UV light engine combines optical lensing with powerful UV LED arrays to provide consistent and powerful exposure, ensuring your parts are uniform every time you print. This cures entire layers with a single flash.

For clinics and small dental labs, the Nexa3D® XiP is the ideal entry into ultra-fast digital dentistry. Combine it with its compact post-processing to keep your environment clean and safe.

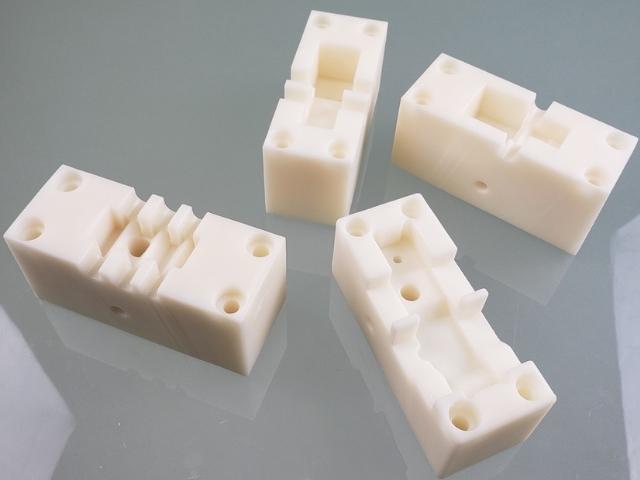

Verify your design before you go into production. Test form, fit and function with an accurate representation of the final product.

Produce complex objects quickly and cost-effectively, in small runs or as individual pieces.

3D printed injection molds can accelerate product development and offer the possibility to produce prototypes with the later original manufacturing process and from the original material.

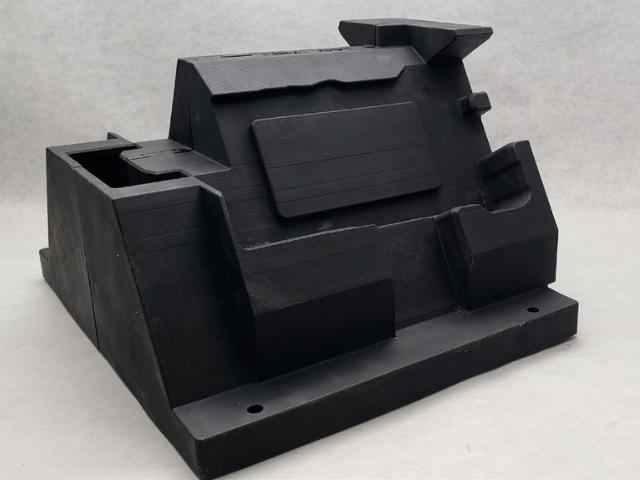

With the Nexa3D® XiP, manufacturing and assembly processes become easier and more reliable, cycle times are shortened and worker safety is improved.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy