3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

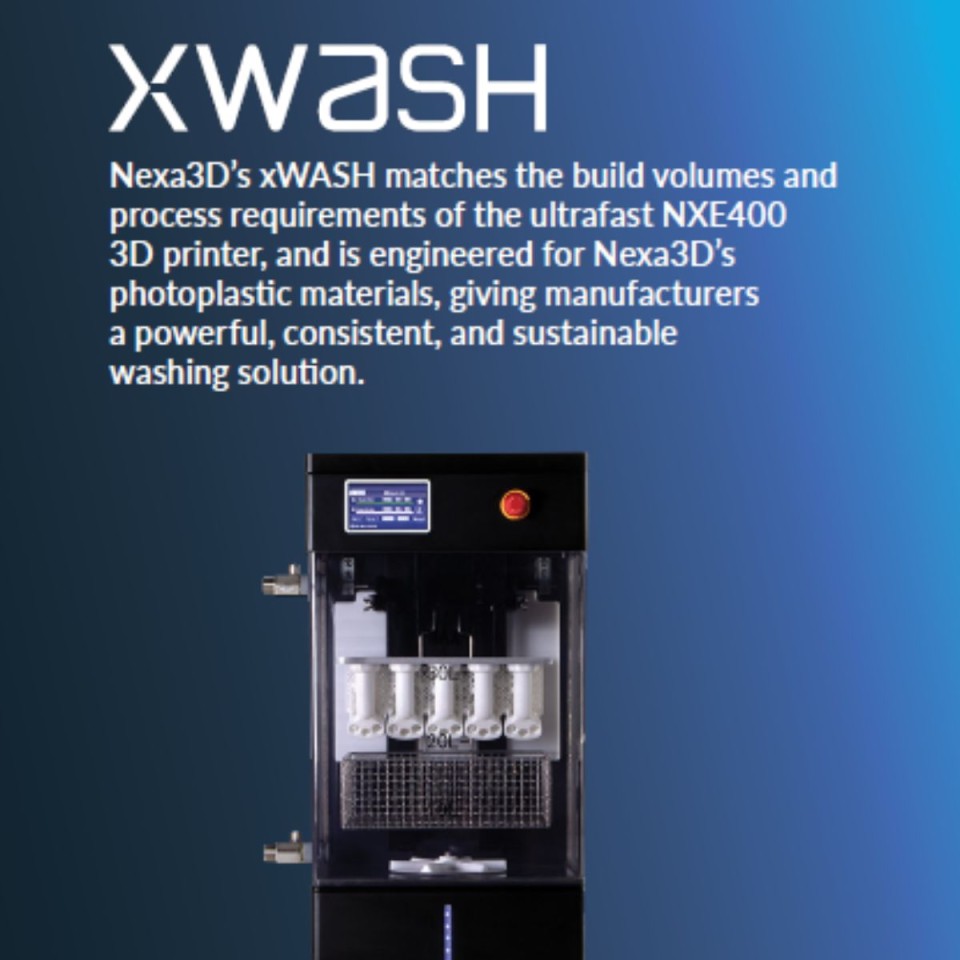

Build volumes and process requirements for the Nexa3D® NXE 400Pro, NXE 200Pro and NXD 200Pro are met by xWash post-processing technology. This provides manufacturers with a strong, reliable and durable post-processing option.

xWash from Nexa3D® matches the build volume and process requirements of the ultra-fast Nexa3D® NXE/NXD 3D printer and is designed for resin 3D printers. Bidirectional agitation of the fluid at variable speeds ensures efficient cleaning regardless of part geometry. In addition, the process time can be adjusted using an adjustable cleaning timer. Dedicated drain and fill ports facilitate maintenance, and a pot life timer alerts when the cleaner has reached saturation. The Tritan plastic container provides clear process visibility and cleaner level indication, offering maximum durability for production environments. The ability to automatically raise and lower the Z-axis with a second lid/cover provides additional protection from chemicals and reduces solvent evaporation.

The Nexa3D® xWash features a touchscreen user interface with an adjustable cleaning cycle timer, fill and drain port, 40-liter Tritan tank, automatic Z-stage agitation, and a bi-directional variable speed agitator.

For greater production flexibility, xWash accepts components attached to the NXE and NXD build platforms or a loose parts basket. Up to 2x NXE/NXD build platforms and/or a loose parts basket.

For Nexa3D® xCLEAN, improved chemical and flash point safety properties, triple saturation limits compared to isopropanol, and environmentally safe recycling alternatives have been validated and further developed.

xWash from Nexa3D® can also be used for other SLA and DLP 3D printers. Wash times can be individually adjusted to the needs of the processed material.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy