3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

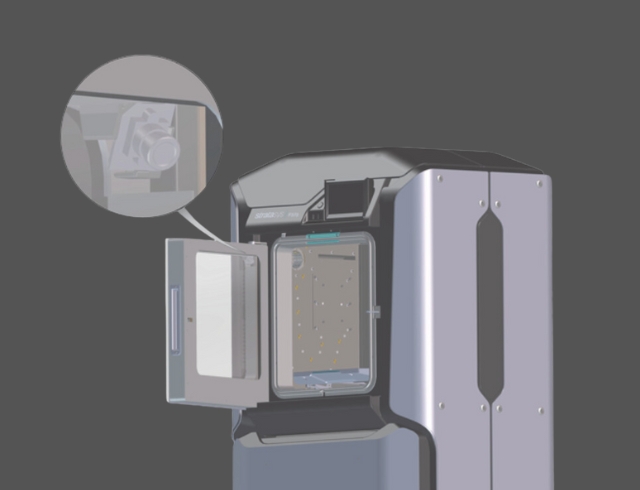

The Stratasys® F170 3D FDM® Printer satisfies even the most demanding requirements for end-use parts and rapid prototyping while requiring less expertise and understanding. All phases of the design process are where this printer shines, from draft-concept revisions to intricate design verification to producing high-caliber functional parts.

In the realm of 3D printing, the Stratasys® F170, a member of the Design Series, is a significant advancement. It is a logical upgrade for owners of the Dimension Elite and Dimension 1200es, as it is constructed on a whole new platform to be quicker and less expensive than its predecessors.

The F170 is a multi-material printer that offers a build volume of 254 x 254 x 254 mm and the ability to load two material reels at once. It is a fully functional prototype tool. Though PLA has traditionally been associated with lower-end, hobbyist use, cost-conscious customers can utilize it to generate test prints, and putting it in a printer like this helps cut the cost of iterative development. This is especially true when used in conjunction with the F170's quicker, more economical draft mode.

The soluble backing material and the heated print tray allow for the creation of stable, distortion-free plastic components.

Technical Specifications:

Build Volume: 254 x 254 x 254 mm

Material Bays: 2 in total (1 model / 1 support)

Accuracy: +/- 0.2 mm or +/- 0.002mm/mm, whichever is greater

The F170 comes with an automatic calibration system that removes human error in printing. It has better tray insertion, engagement and levelling. It has automatic Z calibration with every job. It has less tip interference with the build sheet and it comes with precise motion components that produce longer-lasting, more accurate constructions.

The F170 is built with high performance durable components. It has a high strength steel frame, ⅛” aluminium exterior with slot and tab construction, tempered glass and is insulated for noise and heat resistance.

The F170 comes with advanced servo motors that have better control and movement precision. It has faster filament status, alert and response and has fewer pauses and failed builds because of a cross wound spool. It has linear profiled rails and ball bearings that are smoother and quieter with precision timing belts and precision Z stage ball screws.

The F170 can print high standard materials such as PLA which is the most economical, ASA which has good UV stability, ABS which has balanced properties, TPU 92A and QSR support material which is soluble.

Of the two material bays on the F170, one is meant for a model bay and the other one is meant for a support bay for a wide range of printable materials in one go.

The F170 has two build speeds which are Regular Build Mode and Draft Mode which uses ⅔ less material than regular build mode and prints at double the speed. It offers two spool sizes with many colour choices. It has 4 slice heights (5, 7, 10 and 13 slices). It has 4 fill styles and 5 support styles.

The F170 comes with redundant sensors for door locks and switches. It also has a number of heat and motion disablers, voltage monitoring and continuous monitoring and notifications via user interface.

Call or email us and we will be happy to help you.

The F123 Series printers make it feasible to produce small-batch production runs and custom items that would otherwise be too expensive to produce using conventional machining or molding techniques. Limitless design freedom is possible with soluble support and robust materials.

Materials designed especially for 3D printed fixtures, jigs, and manufacturing tools can improve the ergonomics and worker-friendliness of your tooling and factory floor.

Compared to conventional prototyping techniques, you may iterate your designs considerably more quickly with the user-friendly F123 Series printers. The printer is appropriate for both the office and the manufacturing floor due to its small size and silent operation.

Schools can use the F123 Series systems as the ideal 3D printers. They are an excellent tool for teaching students highly sought-after skills required in manufacturing, design, and engineering vocations because of their simple use and integrated safety measures.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy