3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

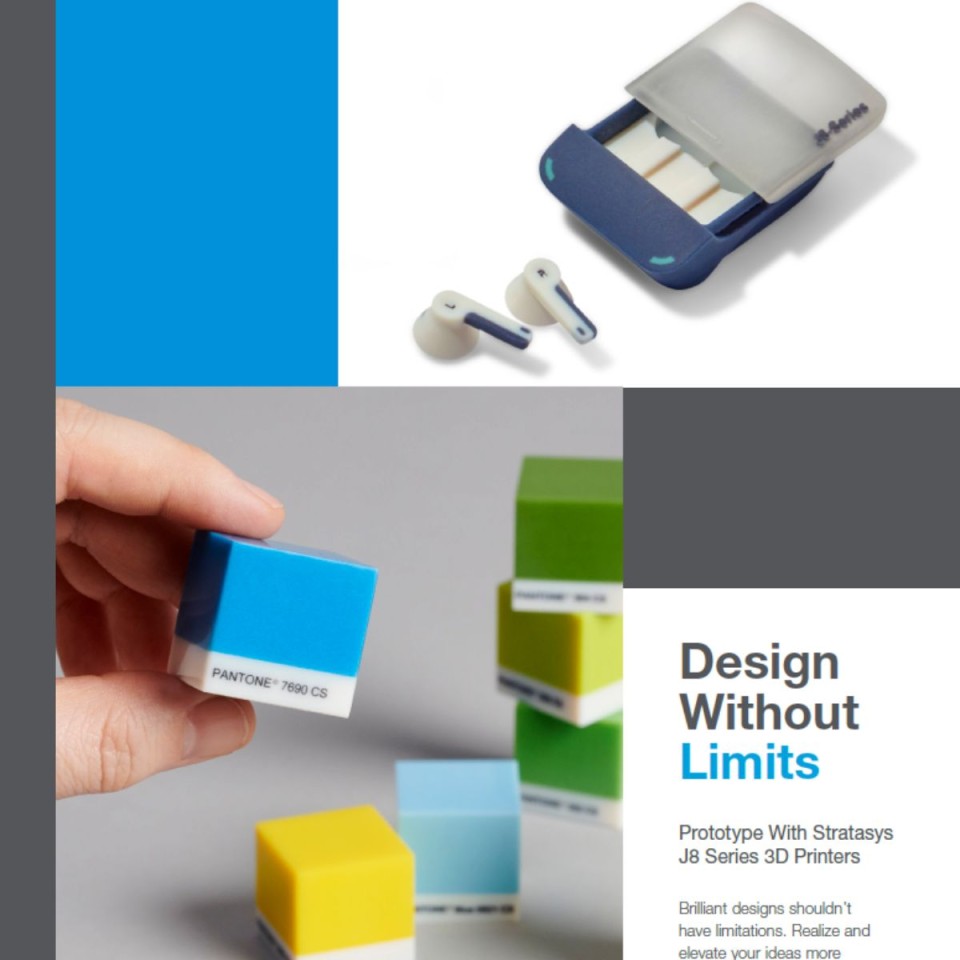

Make prototypes that resemble the final product in both appearance and feel. Simulate a variety of realistic textures or use transparent materials to achieve more realistic finish for your prototypes.

One of the most adaptable full-colour printers available is the J826™ Prime, which boasts over 500,000 unique colours, realistic texture simulation, flexible and transparent materials, and a click-and-print methodology.

A J826™ Prime 3D printer allows you to produce five times as many design iterations in the time it takes to produce a single prototype using conventional techniques. With its spacious eight-material capacity, this small design lets you load your most often used resins and eliminates the downtime that comes with switching out materials.

Additionally, J826™ Prime comes with 3 build modes that accommodate a variety of customer requirements: High Quality Mode, High Mix Mode and High Speed Mode.

Technical Specifications:

Build Size: 255 x 252 x 200 mm

Layer Thickness: Horizontal build layers down to 14 microns

Build Modes: 3

Up to seven different materials and one support material can be printed simultaneously using the J826™ Prime, allowing for the fabrication of parts with a wide range of characteristics, such as stiff, flexible, transparent, and opaque materials. With this multi-material capability, customers can print jobs that mix many materials without the requirement for assembly or post-processing.

Three unique build modes are available on the Stratasys® J826™ Prime 3D printer to accommodate a variety of customer requirements. The highest level of accuracy and detail is achieved at a resolution of 14 microns by using up to seven base and one support resin in the High Quality Mode. The High Mix Mode, which likewise allows up to seven base and one support resin but at a somewhat lower resolution of 27 microns, is the ideal mixture between quality and printing speed. Lastly, the High Speed Mode employs up to three base and one support resin at a resolution of 27 microns for faster printing of concept models.

The J826™ Prime comes with a built-in workstation with a touch screen that doesn’t require a keyboard or mouse, it has a removable tray for easy cleaning and swapping and it has a 16 4kg cartridge capacity that auto swaps when low on material.

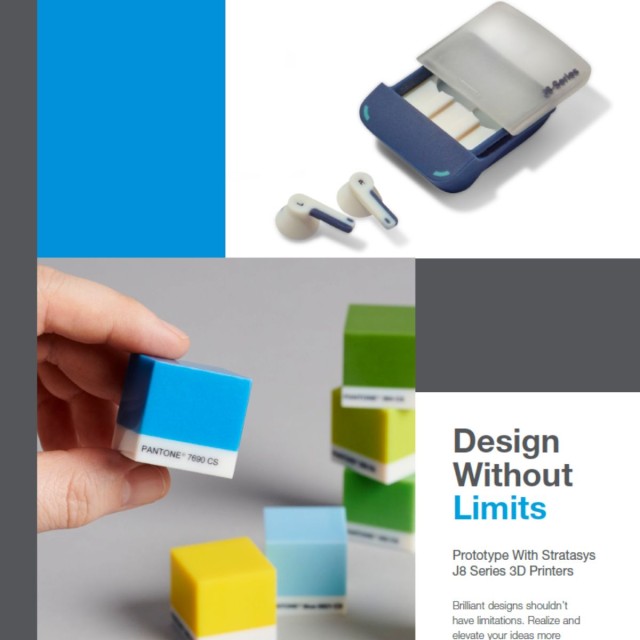

The J826™ Prime offers Pantone® colour validation, enabling 3D printing of the Pantone® Matching System (PMS) colours. Compared to traditional paint matching or iterative colour matching techniques, this capability saves time and costs by enabling exact colour matching and the construction of colourful, realistic prototypes.

Design using more than 500,000+ distinguishable colour combinations plus clear and attain texture realism from matte to glossy surfaces, simulating materials like leather, wood, stone and more with horizontal build layers down to 14 - 27 µm layer thickness.

The GrabCAD Print™ software is compatible with the Stratasys J826™ Prime 3D printer and enhances the capabilities of the printer's PolyJet™ technology with an intuitive interface and cutting-edge functionality. By enabling users to print straight from their preferred professional CAD formats, GrabCAD Print™ software offers reduced print prep time and gives users exact control over file preparation, print parameters, and material selection. The software has smart default settings, tooltips, and notifications to help users navigate a streamlined printing workflow, minimising material waste and increasing cost and time savings. It also integrates with the Pantone® Matching System (PMS), enabling accurate colour matching for 3D printed models. Furthermore, GrabCAD Print™ provides capabilities for extensive visualisation, including print tray, slice previews, and models.

Call or email us and we will be happy to help you.

With the material and technological capabilities of the J826™ Prime, certain industrial design applications can be met. Applications such as: simulated fabric light pipes, PC appearance, matte surface, grey finish mimicking metallic finish, glass thickness simulation, 2D graphics, glass simulation, liquid simulation, rubber simulation, saturated colours and colour standards and wood simulation.

The J826™ Prime can be used for engineering applications such as fit and form, functional testing, see through parts, finite element analysis, optical transparent modelling, labelling, light components, sectioning and versioning and fluid channels.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy