3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

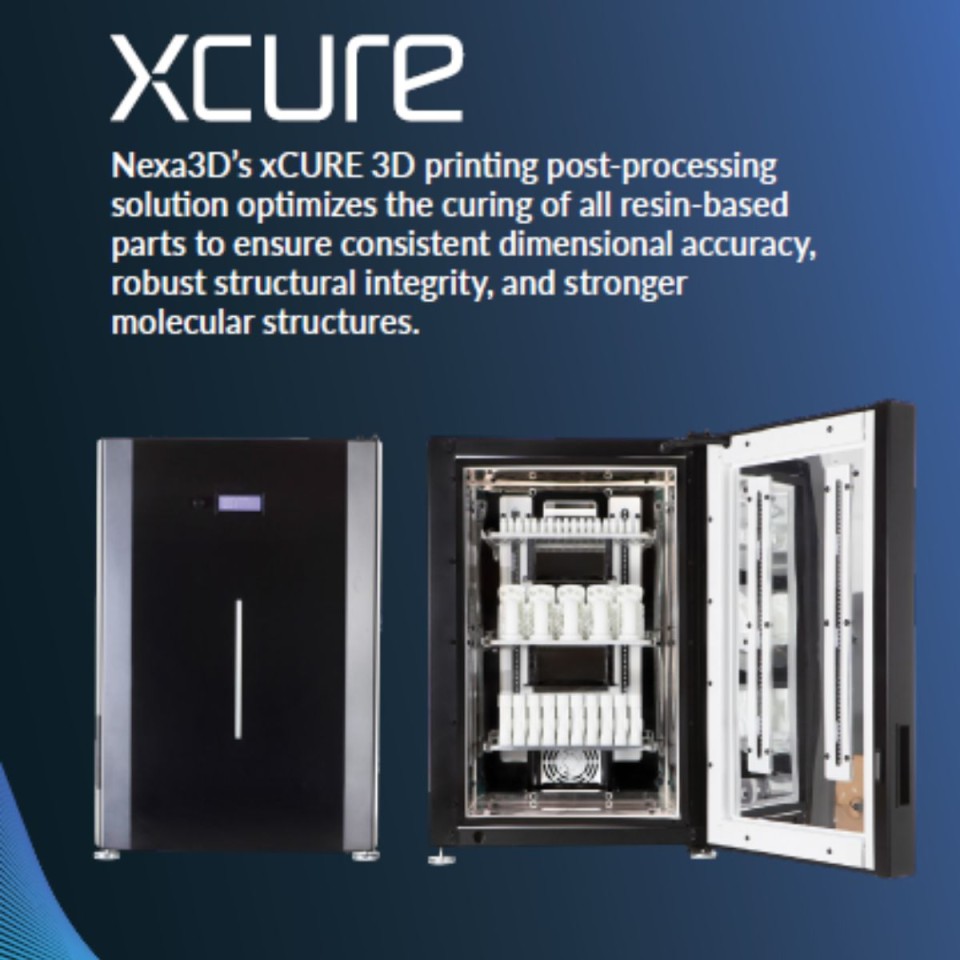

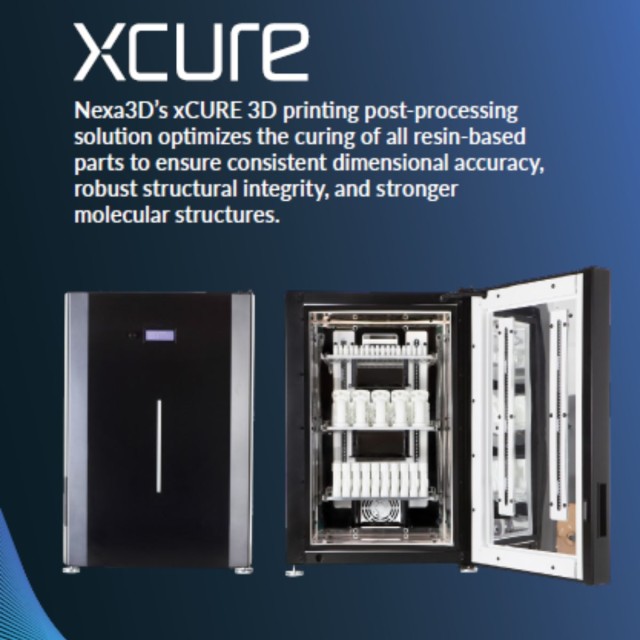

Build volume and process requirements for the Nexa3D® NXE 400Pro, NXE 200Pro, and NXD 200Pro are met by xCure post-processing technology. This provides manufacturers with a strong, reliable, and durable post-processing option.

All SLA and DLP parts must be post-cured after the printing process. Post-curing resin parts maximizes material properties, improves part strength, and enables consistent and repeatable mechanical performance.

Nexa3D® xCure combines heat and UV to cure 3D printed parts. xCure has a 16-liter capacity and is designed to process the entire build space of the Nexa3D® NXE/NXD printer. The chamber can hold up to three build plates at a time and allows parts to cure directly on the build plate.

The chamber is designed to process the full print range of Nexa3D®'s NXE and NXD printers and can handle parts up to 16 liters in volume. The chamber can accommodate up to three build plates at a time and allows parts to be cured either directly on the build plate or independently on clear shelves.

High-power dual-wavelength LEDs and sequential UV and thermal curing modes are also available. The unit operates in three curing modes - UV only, heat only, and UV+heat - and is built to international industrial design and safety standards.

LEDs with a wavelength of 365+405 nanometers provide a broad spectrum for the deepest possible cure. Six LED strips with reflective inner surfaces and 360-degree coverage provide maximum consistency.

In a controlled chamber, you choose from a list of pre-set sequences that are material specific. It can be easily upgraded for additional materials and is preloaded with validated cure sequences for all approved Nexa3D® photopolymer materials.

xCure from Nexa3D® can also be used for other SLA and DLP 3D printers. All exposure times and temperature values can be individually adjusted on the UV chamber.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy