3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

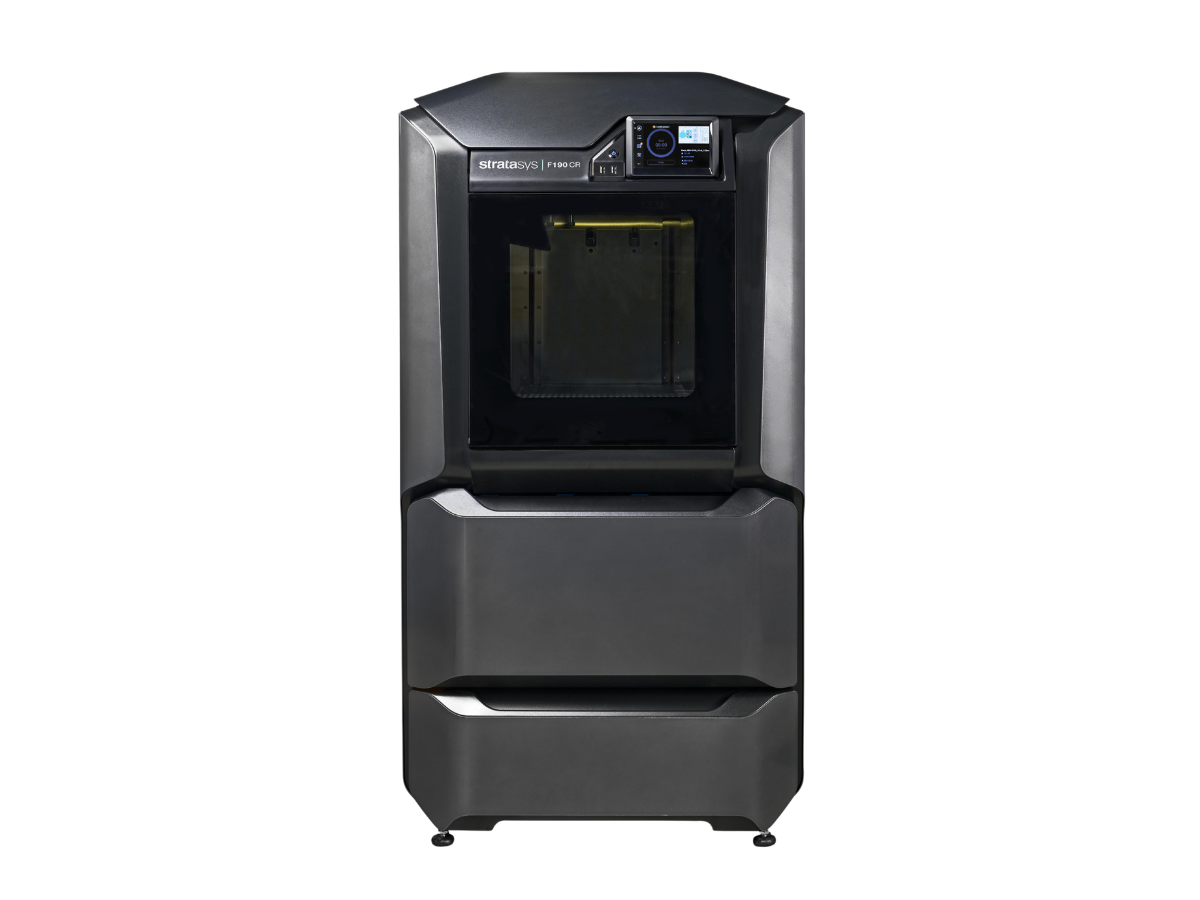

The F190™CR is a composite printer that provides high-strength carbon fiber materials in a dependable, user-friendly industrial printer platform. It is part of the F123CR (Composite Ready) Series and has a slightly smaller build size compared to the F370®CR with 2 material bays.

High-strength 3D printed composite parts can be used by industrial producers in place of metal components thanks to the F190™CR printer, which complements conventional fabrication processes. The ABS-CF10 and FDM® Nylon-CF10 composite materials used in the F190™CR are both 10% weight-based and reinforced with chopped carbon fiber for strength and stiffness. Complex designs that cannot be produced with traditional machining or other 3D printers without this capability can now be generated thanks to F123CR soluble support material. You may choose your print speed and part quality with four layer resolutions. You can create fully dense, solid parts with variable part density, or you can change the infill to reduce weight and material consumption.

With the F190™CR, you may expand your use cases by printing on a wider range of engineering thermoplastics. With this multi-material capacity, printing various jobs on various materials is made convenient. Printers specifically designed for printing composite and non-composite materials are not required. Don't close off any choices. Purchase a single printer and benefit from a variety of materials.

Technical Specifications:

Build Size: 305 x 254 x 305 mm

Build Volume: 23,600 cc (1,440 ci)

Slice Heights: .330 mm, 0.254 mm, 0.178 mm, 0.127 mm

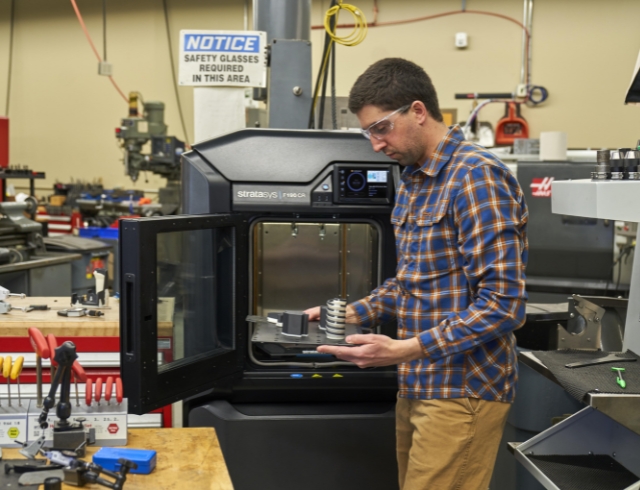

With a hardened system that is composite ready, the F190™CR can print strong composite and abrasive materials. It has the ability to produce dense parts in a fully heated build chamber for higher accuracy and strength in Z. Replace traditionally machined metal components with high-strength 3D printed composite parts. Avoid costs of using limited production resources or the lead time of outsourcing. With composite 3D printing, you can create fixtures, soft jaws, component parts, and more in a fraction of the time and money compared to metal machining.

The F190™CR composite printer has a certified 99% uptime and a 99% dimensional repeatability performance, and is constructed on the same platform as the well-established F123 Series. Successful print outcomes and consistent material performance across all resolutions are guaranteed by material tuning, which is the optimization of print parameters using more than 220 measures. Print heads and hardened components are the first steps in ensuring built-in durability through the use of abrasive composite materials.

There are 6 different types of extrusion heads for the F190™CR. A standard extrusion head that can also be used as dedicated “support”, a PLA extrusion head, an elastomer extrusion head, an ABS CF10 extrusion head, a CR extrusion T20 hardened head for Nylon-CF10 and future materials and a CR Extrusion T14 hardened head for ABS-CF10.

The F190™CR has two sealed and desiccated material bays. The bays ensure reliable material properties for a wide range of materials.

The F190™CR comes with a reusable flexible build tray that requires no special build plate preparation such as build plate cleaning before builds, special application of chemicals like glue sticks, etc. and comes factory levelled.

Setting up print jobs is easy with GrabCAD Print™ software; simply import the CAD file for the part, and the program creates toolpaths and supports. The same print head will print at many resolutions, saving manufacturing changes. Click "Print" and turn to leave. No supervision is required until the print job is finished.

Get advanced results with minimal training. The F190™CR comes with an intuitive 7” (18cm) full colour touchscreen interface, built in camera for remote monitoring with full system monitoring panels for reporting time to print, time remaining, layer currently printing, filament remaining, job queue monitoring and ability to modify queue at machine or remotely. It supports 11+ languages on the user panel and also has automatic tip offset calibration adjustment.

The F190™CR has successful insertion confirmation for build trays. Its keyed inserts are intuitively designed to assure spool is seated and ready for filament loading. It comes with a solid free standing frame and design for stability, smooth gliding drawers for filament bays, safety switches and locks to prevent injury, easy to roll on casters and it can plug into a regular wall outlet.

With the power of MTConnect it is easy to integrate the printers into a connected factory floor. This industry standard communication API lets you collect, analyse and display machine data in a useful way

Call or email us and we will be happy to help you.

Use quick, iterative functional prototyping to use the high strength capabilities of composite 3D printing to speed up manufacturing.

Carbon fiber materials enable the use of 3D printed soft jaws, fixtures, and production aids in place of robust and stiff machined metal.

The mechanical characteristics needed for production parts and low-volume, industrial-grade components are provided by composite 3D printing materials.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy