3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

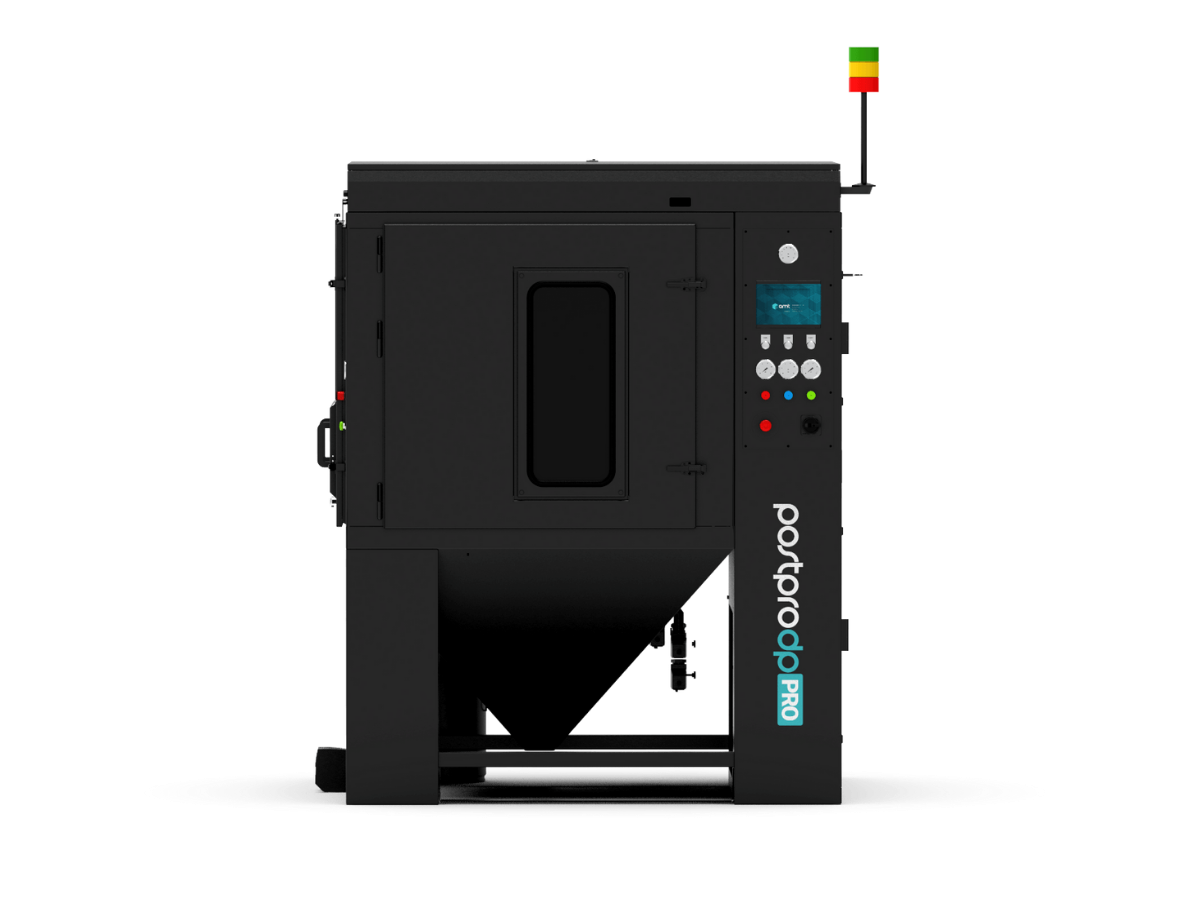

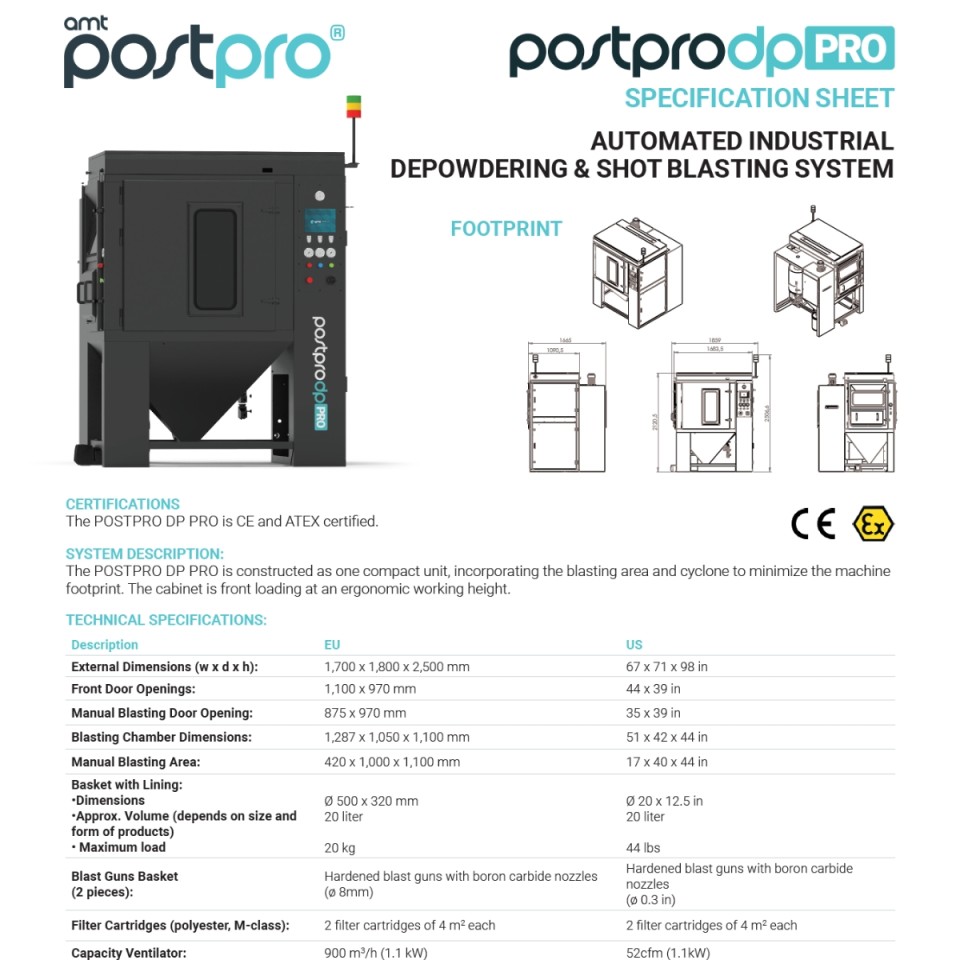

The PostPro DP PRO is a fully automated, 2-in-1 depowdering and shot blasting system designed to efficiently clean both large and small 3D printed parts, significantly enhancing throughput in post-processing workflows.

The PostPro DP PRO is an advanced automated depowdering and shot blasting device that improves the post-processing capabilities of 3D printed products. This sophisticated machine incorporates a dual-functionality approach that enables quick depowdering and surface finishing, making it perfect for high-volume production situations. With a maximum load capacity of 20 kg, the PostPro DP PRO is designed to handle a wide range of part sizes and geometries, expediting the cleaning process and guaranteeing that each component satisfies strict quality standards. By automating these previously labor-intensive procedures, the system considerably decreases manual intervention, boosting throughput while lowering operational expenses associated with post-processing.

One of the PostPro DP PRO's distinguishing features is its specialized manual blasting section, which allows operators to quickly clean larger components without disrupting the automated depowdering process. This flexibility is critical in high-demand industrial environments where time efficiency is vital. The system's ergonomically constructed basket is easily adjustable to optimize the blasting angle, allowing for quick switching between batches and guaranteeing that each part receives appropriate treatment. Furthermore, once an optimal cleaning formula has been determined, operators can retain these settings for future usage, ensuring consistency across several production runs. This capability not only boosts efficiency, but it also assures that manufacturers can maintain high quality standards across their operations.

Technical specifications:

Blasting Chamber Dimensions: 1287 x 1050 x 1100 mm

Manual Blasting Area: 420 x 1000 x 1100 mm

Basket With Lining Dimensions: Ø500 x 320 mm

Basket Volume: 20 liters

Basket Loading Weight: 20 kg

Blast Gun (Basket): Double with Ø8 mm nozzle

Blast Gun (Manual): Single with Ø8 mm nozzle

The PostPro DP PRO combines two critical processes—depowdering and shot blasting—into one fully automated machine. This dual feature enables manufacturers to easily clean and finish their 3D printed components in a single operation, considerably decreasing the time and labor required for separate operations. By automating both operations, the system reduces the need for human involvement, resulting in faster production and consistent cleaning results across several batches. This capacity is particularly useful in high-volume manufacturing scenarios where efficiency and quality are critical.

One of the PostPro DP PRO's most notable features is its ability to store and remember customized cleaning formulas based on specific materials and geometries. Operators may readily change the pressure, duration, and kind of abrasive material used for each cleaning task. Once an ideal formula has been developed, it can be retained for future usage, guaranteeing that each batch receives the same high-quality treatment. This level of customization enables producers to achieve reproducible outcomes while supporting a wide range of part designs and materials, hence increasing total operational flexibility in additive manufacturing processes.

The PostPro DP PRO contains a dedicated manual blasting area that allows for rapid cleaning of bigger components without disrupting the automatic depowdering operation. This capability enables operators to efficiently handle big components that may not fit into the automated section while still utilizing the system's superior capabilities. The manual blasting area is ergonomically engineered for ease of use, allowing operators to effortlessly transition between automated and manual processes. This adaptability allows producers to maintain high levels of production while dealing with a variety of part sizes and cleaning requirements.

To counteract static charge, which can pull small powder particles back onto cleaned surfaces, the PostPro DP PRO includes innovative ionization technology. This feature produces ionized air that neutralizes static charges throughout the cleaning process, guaranteeing that the parts are dust-free and ready for further finishing operations. By successfully minimizing static build-up, the technology improves cleanliness and quality while decreasing the need for further post-processing procedures. This capacity is especially significant in businesses requiring surface integrity and detail retention, such as dental or jewelry applications.

The PostPro DP PRO features a powerful cyclone dust separation mechanism that effectively removes blast media and dust created during operation. This sturdy filtering system not only keeps the working area clean, but it also improves sight within the chamber, allowing operators to better oversee the cleaning process. Furthermore, the system includes a high extraction rate ventilator that avoids dust accumulation in the working chamber, hence increasing safety and operational efficiency. By ensuring appropriate air quality and cleanliness, this function helps to create a safer working environment while increasing productivity.

The PostPro DP PRO is designed for operator comfort, with an ergonomic layout that allows for simple access to controls and components. The user-friendly touchscreen interface enables operators to swiftly alter settings and monitor activities in real time, making it suitable for users of various technical expertise. Furthermore, the machine's CE accreditation ensures compliance with safety regulations, giving operators peace of mind when operating in potentially dangerous areas. By emphasizing user experience alongside innovative technology, the PostPro DP PRO distinguishes itself as a crucial tool for firms looking to improve their post-processing capabilities in additive manufacturing.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy