3D printers

High quality 3D printers

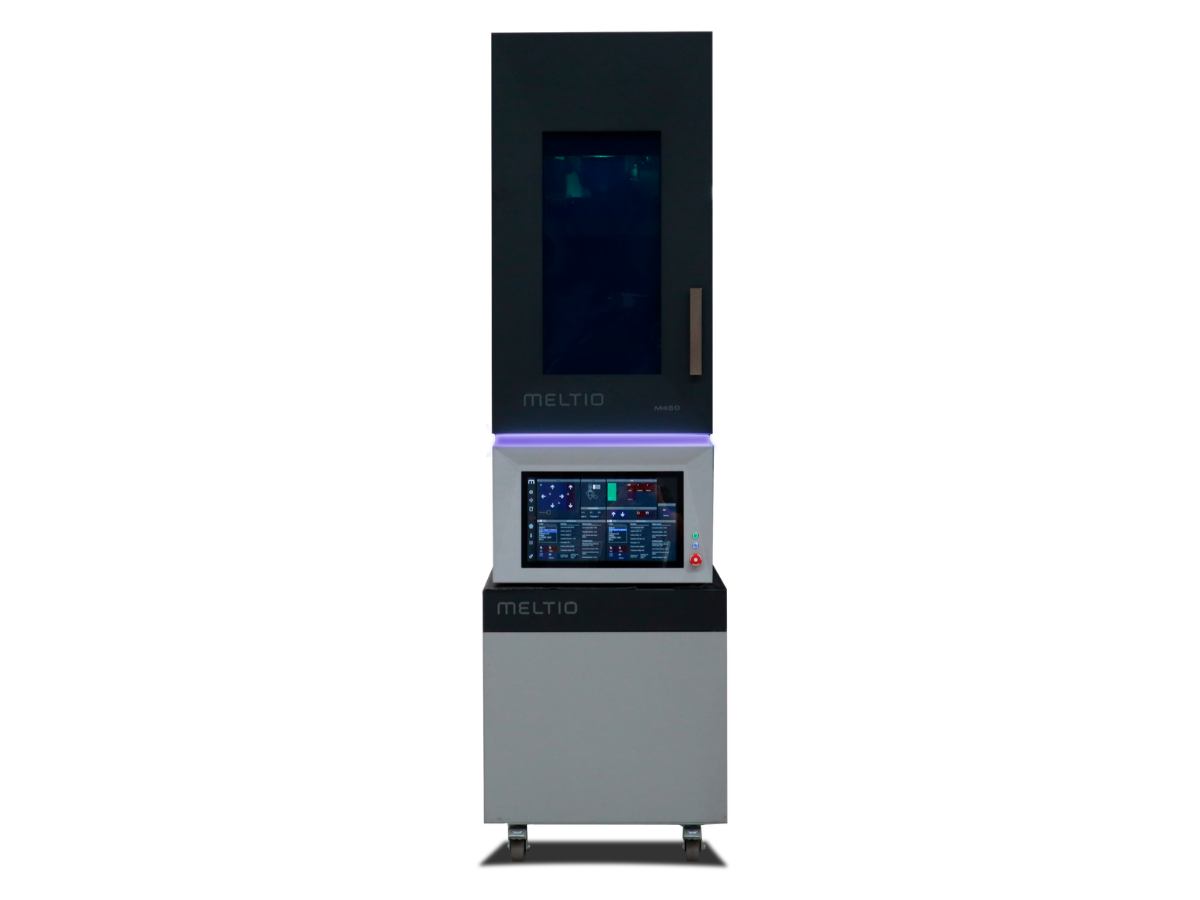

The Meltio M450 produces high-density metal parts using advanced Laser Metal Deposition (LMD) technology, which is a type of Direct Energy Deposition (DED). This unique and compact device enables precise energy distribution and optimal melt pool control.

The Meltio M450 is a cutting-edge compact metal 3D printer that produces high-density metal objects with a unique multi-laser deposition head equipped with six 200W direct diode lasers, totaling 1200W of power at 976 nm.

The system also has closed-loop process control, which enables real-time monitoring and adjustment of laser power and wire feed, resulting in constant part quality.

The M450 has various innovative characteristics, including a hot wire option for faster deposition rates, dual wire capabilities for sequential printing of two materials, and a inert atmosphere for printing reactive chemicals. Its user-friendly interface consists of a powerful onboard computer with a 17" touchscreen and custom-designed software for simple model slicing and parameter control. The Meltio M450, with its mix of advanced technology, material versatility, and user-friendly operation, marks a substantial leap in metal additive manufacturing for industrial applications.

Technical Specifications:

Print Envelope: 145 x 168 x 390 mm

Laser System: 6 200W direct diode lasers, totaling 1200W

Laser Wavelength: 976 nm

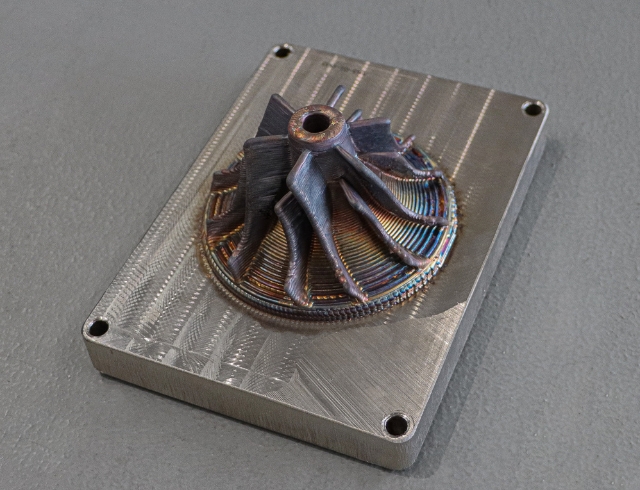

The Meltio M450's multi-laser deposition head is a revolutionary feature that distinguishes it in the world of metal additive manufacturing. This revolutionary device uses six 200W direct diode lasers, totaling an astonishing 1200W of power, all focused on a single deposition point. The unique design provides unprecedented control over energy distribution, allowing for exact manipulation of the melt pool. This level of control leads to optimal material deposition, faster build rates, and higher part quality.

Its direct diode lasers have a wavelength of 976 nm, which is very useful for metal processing. This innovative multi-laser arrangement not only improves efficiency, but also allows for dynamic adjustment of laser patterns and energy input to accommodate diverse materials and geometries. As a result, the M450 can produce fine details, consistent layer formation, and superior metallurgical characteristics in printed products.

Meltio's Hot Wire technology on the M450 is a cutting-edge feature that improves the performance of their metal 3D printing machines. This configurable power source preheats the wire material before it reaches the melt pool, resulting in faster deposition rates and more energy efficiency. The Hot Wire technology enables for faster printing of big parts by lowering the energy required by lasers to fully melt the material, as well as optimising material flow potentially improving the mechanical qualities of the completed components. Its programmability allows customers to customise preheating parameters based on specific materials and part needs, increasing compatibility with a wide range of alloys.

The Dual Wire option further expands the M450's versatility by allowing users to combine different metals such as stainless steel, carbon steel, titanium alloys, and Inconel in a single print job. This feature gives new opportunities for developing parts with optimised performance characteristics, as different regions of a component can be printed using materials that are best suited to their unique needs. The M450's rapid material switching boosts production by eliminating downtime while also allowing for more efficient use of expensive materials. Furthermore, it increases design flexibility, allowing engineers to develop complicated parts with varied material properties throughout their structure.

The Meltio M450's inert environment control is an important feature when working with reactive materials. By providing an inert build chamber atmosphere with an oxygen level of less than 10ppm (parts per million), the system creates an excellent environment for processing oxidation-sensitive materials such as titanium and aluminum alloys. This oxygen-reduced environment is essential to ensuring the quality and integrity of printed parts, as it avoids unwanted chemical reactions that could affect material quality or cause defects in the end product.

Furthermore, the M450's compatibility with various shielding gases, such as argon, nitrogen and helium, allows users to customize the printing environment for different materials and applications. This versatility, combined with the ability to heat the substrate up to 500°C, offers significant advantages in terms of process control and part quality. The high substrate temperature guarantees a strong bond with the preheated welding rod. This ensures exceptional overall stability of the component and prevents the risk of delamination. In addition, controlled heating helps to manage the thermal stress within the part during the manufacturing process, reducing internal stresses.

The Meltio M450's closed-loop process control is an intelligent feature that maintains consistent part quality by monitoring in real time and making adaptive adjustments. High-speed cameras and pyrometers continuously monitor the melt pool's size and temperature, providing critical information to the system. The M450 automatically adjusts laser power and material feed rates based on this information to ensure optimal printing conditions. This adaptive control method detects and corrects anomalies during the construction process, considerably lowering the possibility of defects. The closed-loop process control improves the overall dependability and quality of the printed items by constantly fine-tuning the printing parameters, transforming the M450 into a highly precise and efficient metal 3D printing system.

The Meltio M450 provides exceptional precision and speed in metal 3D printing. With a deposition rate of up to 1 kg/h for steel alloys, it outperforms conventional powder bed fusion systems. The machine's versatility is demonstrated by its adjustable layer height, which ranges from 0.3 mm to 3 mm, allowing for both intricate details and quick creation of bigger structures. This versatility allows customers to tailor their builds for either fine precision or shorter production times. The M450 has exceptional dimensional precision, often achieving ±0.1 mm per 100 mm of part length. The M450's combination of speed and precision makes it an effective tool for a wide range of metal additive manufacturing applications, including prototype and small-scale production.

The Meltio M450 has exceptional material compatibility, making it an excellent choice for a variety of metal additive manufacturing applications. The system can handle a wide variety of metals, including stainless steel, carbon steel, titanium alloys, and Inconel. This diversity enables users to choose the best material for their unique project needs, such as corrosion resistance, high strength, or heat tolerance. The M450's ability to work with titanium alloys is also important, since it offers up new opportunities in the aerospace and medical industries, where lightweight, strong materials are critical. Additionally, Meltio is actively developing capabilities for copper and aluminium, which will broaden the machine's application range.

The Meltio M450 features a comprehensive software ecosystem. At its core is a proprietary slicing algorithm that optimises toolpaths for Laser Metal Deposition (LMD), taking into account crucial issues such as temperature management and structural integrity. This allows for efficient material deposition and high-quality part manufacture. The system has a comprehensive parameter library with pre-set configurations for common materials that can be easily expanded to include custom materials. This versatility enables customers to swiftly tailor the M450 to their individual requirements. Remote monitoring tools provide real-time process observation and management via secure network connections, allowing customers to oversee prints from anywhere. Furthermore, the M450's powerful data logging capability allows for detailed recording of build parameters, aiding quality assurance and process optimization.

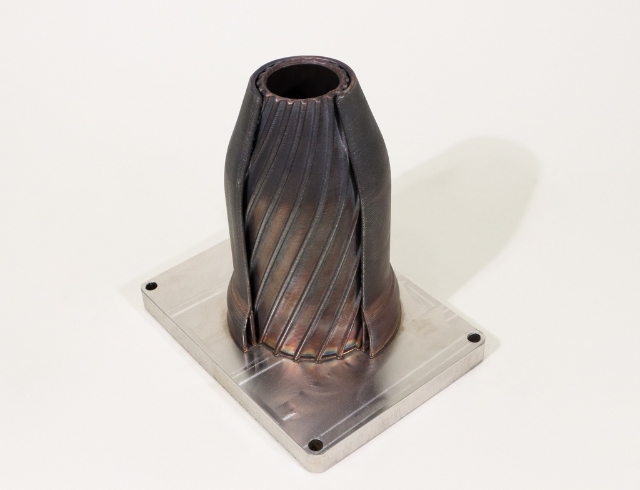

The M450 is ideal for manufacturing complicated, lightweight components for the aerospace and defense industries. Its ability to work with titanium alloys and Inconel makes it excellent for producing high-strength, heat-resistant parts including engine components, structural elements, and custom brackets. The machine's precision and capacity to create fully dense pieces exceed the demanding quality standards of these industries.

For automotive applications, the M450 provides rapid prototyping and small-scale manufacture of specialised parts. Its fast deposition rate and flexibility to work with a wide range of metals make it ideal for manufacturing engine components, exhaust systems, and structural elements. The machine's dual feedstock capacity enables the production of functionally graded materials, which can be especially beneficial in high-performance automotive applications.

The M450 is an excellent tool for materials research and development in both academic and industry environments. Its capacity to work with wire and powder feedstocks, as well as the opportunity to create unique alloys, make it perfect for experimenting with new materials and production techniques. The machine's closed-loop process control and extensive data logging capabilities give academics significant insights into the additive manufacturing process.

The Meltio M450 has substantial benefits for the marine industry, particularly in terms of repair, maintenance, and rapid part production. The M450, as proved by its employment in the French Navy, allows for on-demand fabrication of crucial metal components, such as a replacement spray plate for a ballast air compressor, which was produced in just 5 days rather than weeks through traditional supply channels. This feature is critical for vessels that cannot afford extended periods of downtime or operate in distant places.