3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

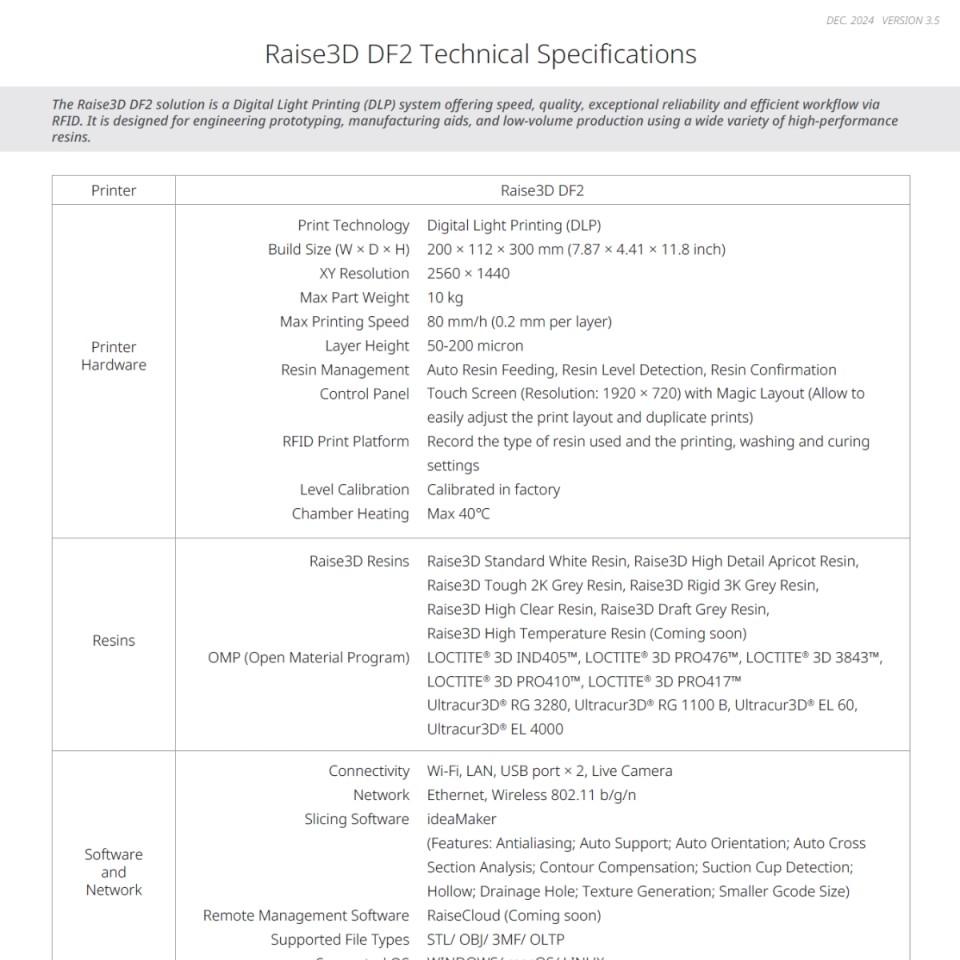

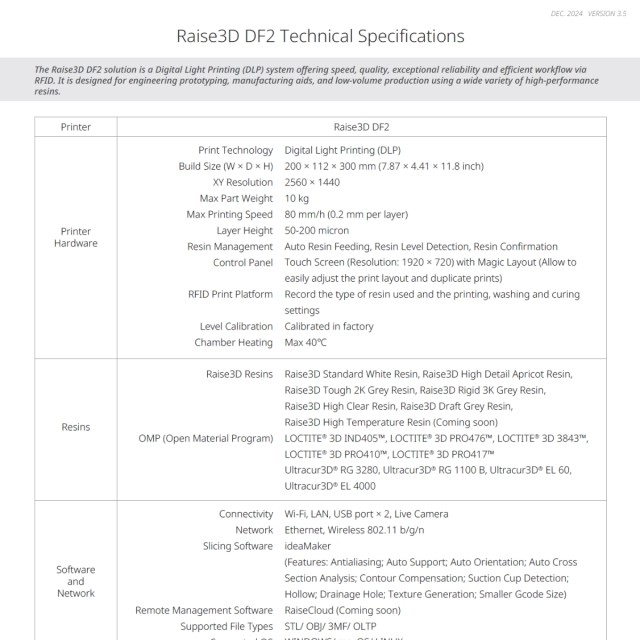

The Raise3D DF2 utilizes Digital Light Printing (DLP) technology, featuring a high-resolution light engine with a DMD chip for precise and rapid 3D printing. This advanced system is complemented by RFID technology, which ensures a traceable workflow throughout the printing, washing, and curing processes.

Utilizing state-of-the-art Digital Light Processing (DLP) technology, the Raise3D DF2 marks a substantial breakthrough in 3D printing capabilities. The DF2's primary light engine is a high-resolution 2560 x 1440 one that has a Digital Micromirror Device (DMD) chip. The fabrication of complex 3D parts with remarkable detail and fine surface finishes is made possible by this advanced system, which precisely projects UV light patterns onto photosensitive resin.

The DF2 is unique because it incorporates RFID (Radio-Frequency Identification) technology into every aspect of the printing process. This intelligent technology creates a smooth and traceable workflow by extending beyond the printer itself to include the cleaning and curing stations. By enabling automatic material recognition and parameter optimization, the RFID tags on resin bottles and build platforms greatly lower the possibility of human error and guarantee consistent print quality.

Technical data:

Build Size: 200 x 112 x 300 mm

XY Resolution: 2560 x 1440

Layer Height: 50-200 microns

Max Printing Speed: 80 mm/h (0.2 mm per layer)

The DF2 has a high-resolution 2560 x 1440 light engine that uses Digital Light Processing (DLP) technology. It has a DMD chip for accurate 3D printing. With the help of this sophisticated optical system and its 50–100 micron layer height capacity, complicated engineering prototypes and elaborate model designs may be produced with remarkable accuracy and flawless surface finishes. The printer is perfect for applications ranging from small, intricate parts to bigger prototypes because of its ability to capture precise details.

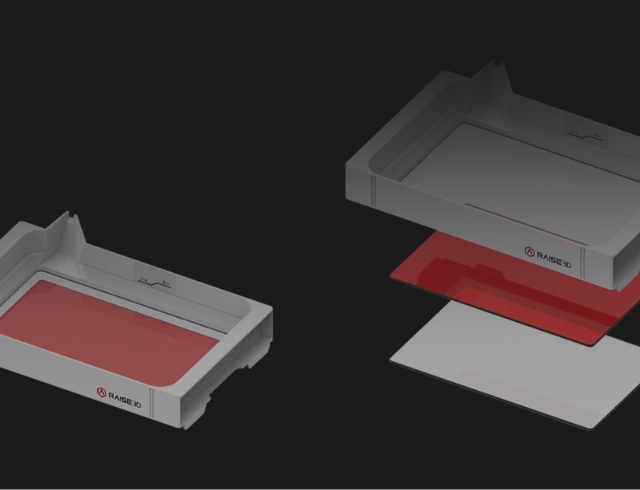

The integration of RFID technology across the whole printing ecosystem is one of the DF2's unique features. RFID tags on the smart build plate automatically store and read pertinent parameters for the processes of printing, cleaning, and curing. A traceable and effective workflow is ensured by the smooth integration of the DF2 printer, DF Wash, and DF Cure stations, which lowers the possibility of human error and drastically cuts down on operating expenses and time.

The DF2's 10.25-inch high-resolution touchscreen (1920 x 720) allows users to use its cutting-edge Magic Layout feature. Before beginning the printing process, customers can quickly modify the print arrangement and make duplicate prints right on the printer's interface thanks to this capability. The Magic Layout function significantly speeds up and streamlines the preparation process by allowing for quick and easy layout adjustments, increasing overall productivity. Automatic Pre-Print Inspection is part of this function and verifies a number of all working conditions including build platform installation, feeding station installation, resin margin, resin type and many more.

The printing process is greatly enhanced by Raise3D's exclusive Air-Peel technology, which is used in the DF2. By using this technology, the peel force is decreased from 50 kg to 10 kg by forming an incredibly thin layer of air between the resin vat bottom and the optical glass. Because of the more effective layer separation made possible by this force decrease, printed items have better isotropic qualities, faster print rates, and higher print quality.

To guarantee seamless and continuous printing, the DF2 has a clever material management system. It has an automatic dosing mechanism that refills the resin container as necessary, as well as an ultrasonic liquid level detecting module that detects low resin levels. The workflow is further streamlined by this technology, which reduces the need for manual intervention and maintains uniform print quality throughout the process.

The DF2 has an open resin program that enables it to work with a large range of high-performance resins from both the manufacturer and outside vendors, even though it is optimized for Raise3D's own resin line. Because of its adaptability, the DF2 can be used for a variety of tasks, including as low-volume production, manufacturing aids, and engineering prototypes. The printer's potential applications in a variety of industries are increased by its capacity to process both common resins and specialist high-resolution, transparent, long-lasting, and heat-resistant materials.

Sharp layer reproduction is ensured by the printer's use of high-quality parts, such as Schott Germany's optical glass, Texas Instruments' Industrial-Grade DMD Chip, and High-Transparency nFEP Film. It comes with a heavy-duty Z-axis structure that can hold and withstand a weight of up to 200 kg of static load. Users can remotely start printing, export logs, and keep an eye on their printers by integrating the DF2 with RaiseCloud 1.0. Additionally, the DF2 makes use of the ideaMaker slicing software, which has capabilities like Hollow and Drainage functions, Suction Cup Detection, Auto Cross Section Analysis, Auto Support, Auto Orientation, Contour Compensation, and Antialiasing.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy