3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

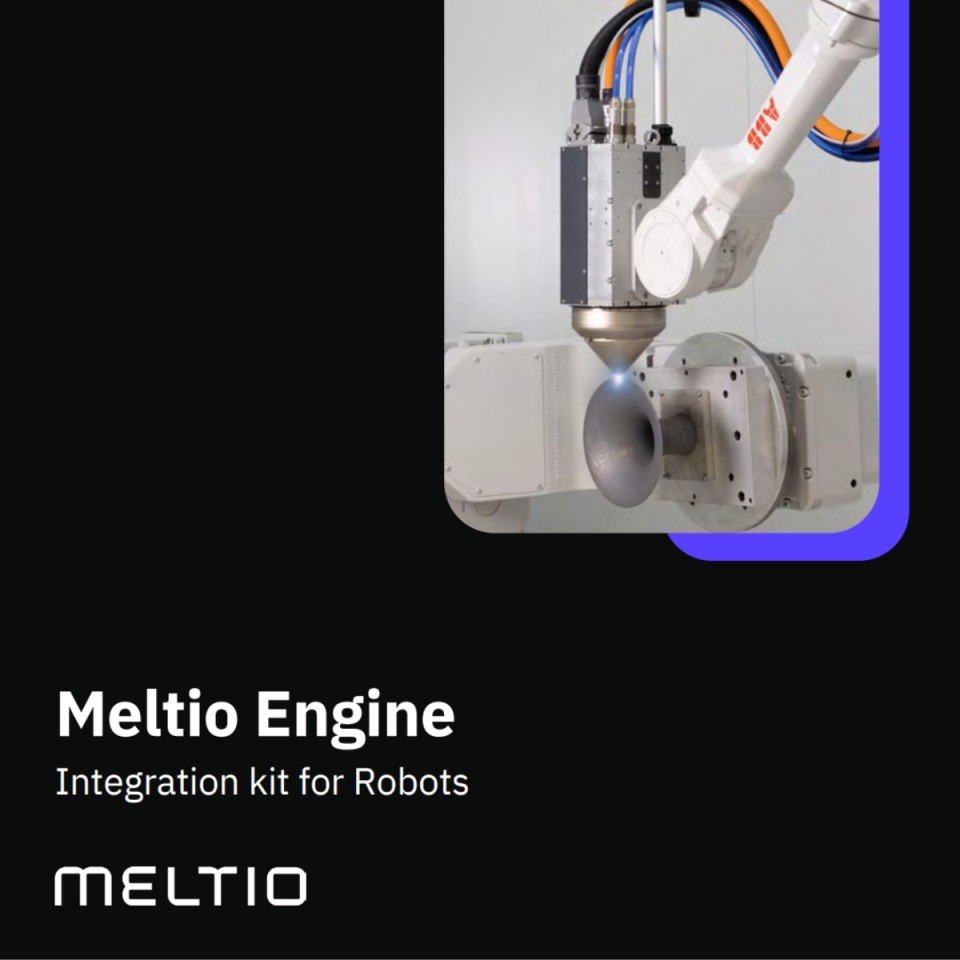

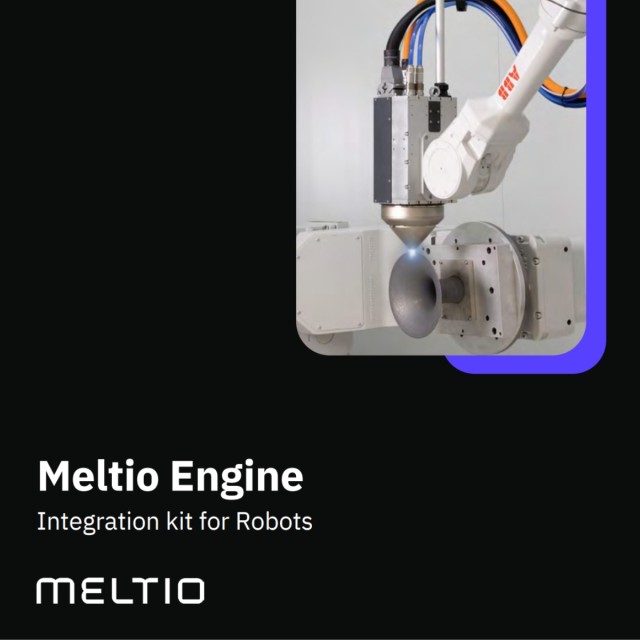

The Meltio Engine Robot Integration employs Wire Laser Metal Deposition (LMD) technology, allowing for the production of fully dense metal parts with directional uniformity and seamless integration with robotic arms for large-scale additive manufacturing applications.

The Meltio Engine Robot Integration is a novel technique for converting industrial robot arms into adaptable metal 3D printing systems. This integration takes advantage of Meltio's innovative wire-laser deposition technique, allowing for large-scale and complicated metal additive production without size limits. The system's working envelope is only limited by the size of the robot's motion system, which allows for the creation of large components and sophisticated geometries with limitless degrees of freedom.

The Meltio Engine Robot Integration is designed for flexibility and efficiency, making it ideal for a variety of applications such as large-scale 3D printing, repair, cladding, and feature addition. It is compatible with a wide range of robot arm manufacturers and interfaces, making it applicable to a variety of industrial environments. The system runs on an open materials platform that accepts stainless steel, mild steel, titanium, and Inconel. The Meltio Engine Robot Integration, which includes a configurable power supply for preheating materials and dual wire printing choices, provides increased deposition rates and material variety. This solution is especially useful for enterprises that require large, complicated metal parts or want to increase their manufacturing capabilities using additive technology.

Technical Specifications:

Print Envelope: Depends on the Integration

Laser System: 9 diode lasers with a total of 1000 watts

Laser Wavelength: 450 nm (blue)

The system transforms robot arms into metal 3D printing platforms that have no inherent size limitations. The working envelope is only limited by the size of the robot's motion system, enabling for the creation of massive and complicated items that would be unfeasible or prohibitive with traditional 3D printing technologies. This capability opens up new opportunities for sectors that need large metal components.

By utilizing the M600 print head, the Blue Laser technology is also utilized in the Meltio Engine Robot Integration. These 450nm wavelength blue lasers significantly increase speed – an amazing 60% when comparing the M450 to the M600 print head – when compared to traditional near infrared and green lasers. In addition, these blue lasers reduce energy consumption because light with a shorter wavelength has higher absorption rates. This also increases the range of materials, making the Meltio Engine Robot Integration highly effective with reflective materials such as copper and aluminum.

The combination of the Meltio Engine with robotic arms allows for the production of extremely complicated parts with limitless degrees of freedom. This characteristic enables manufacturers to bypass traditional manufacturing limits, allowing them to create sophisticated geometries that were previously impossible or prohibitively expensive to actualize. The system's capacity to print in numerous orientations and angles allows for unprecedented flexibility in part design and production.

The Dual Wire option further expands the Meltio Engine Robot Integration's versatility by allowing users to combine different metals such as stainless steel, carbon steel, titanium alloys, and Inconel in a single print job. This feature gives new opportunities for developing parts with optimised performance characteristics, as different regions of a component can be printed using materials that are best suited to their unique needs. The Meltio Engine Robot Integration's rapid material switching boosts production by eliminating downtime while also allowing for more efficient use of expensive materials. Furthermore, it increases design flexibility, allowing engineers to develop complicated parts with varied material properties throughout their structure.

The Meltio Engine Robot Integration continuously checks and adjusts important printing settings in real time, ensuring that part quality remains consistent throughout the process. This control system's closed-loop design allows it to automatically compensate for any deviations from the planned parameters, lowering the likelihood of faults and improving overall part quality. Laser modulation provides fine control over the energy input, adjusting to changes in material properties or geometry to maintain ideal melting conditions. Simultaneously, the wire modulation system adjusts the feed rate and location of the metal wire, enabling precise material deposition. This synergistic management of laser and wire allows the system to respond dynamically to variables in the printing process, such as changes in heat accumulation or component geometry.

The Meltio Engine Robot Integration's Hot Wire function is an innovative capability that dramatically improves system performance and efficiency. This configurable power supply is intended to preheat metal wire feedstock before it enters the melt pool formed by the lasers. Preheating the wire allows the system to reach higher deposition rates since the lasers use less energy to thoroughly melt the material. This leads to higher printing speeds, particularly for large components, and increased energy efficiency. The Hot Wire system's programmability enables customers to fine-tune the preheating parameters based on specific materials and part needs, giving them more flexibility and control over the printing process. Furthermore, preheating the wire can improve material flow and possibly improve the mechanical qualities of printed components by lowering thermal stress.

The Meltio Engine Robot Integration has exceptional material compatibility, making it an excellent choice for a variety of metal additive manufacturing applications. The system can handle a wide variety of metals, including stainless steel, mild steel, carbon steel, titanium alloys, nickel alloys and even copper and aluminium. This diversity enables users to choose the best material for their unique project needs, such as corrosion resistance, high strength, or heat tolerance. The Meltio Engine Robot Integration's ability to work with titanium alloys is also important, since it offers new opportunities in the aerospace and medical industries, where lightweight, strong materials are critical.

This technology excels at processing crucial materials like titanium and Inconel, which are essential for aerospace applications. The system's large-scale printing capacity allows for the creation of huge components, while its ability to construct complex geometries makes it easier to manufacture intricate parts such as blisks and turbine blades. The technology's ability to produce lightweight, hollow structures is particularly useful in aircraft applications where weight reduction is critical. Furthermore, the system's repair and feature addition capabilities provide useful solutions for maintaining and updating high-value aerospace components, potentially lowering costs and increasing equipment lifespan.

The system's capacity to generate complex parts with varying diameters and layer heights is very useful when making manifolds and exhaust headers. This technology enables the rapid prototyping and production of unique parts, which is critical in the fast-paced world of car development and racing. The ability to design lightweight, efficient structures can result in considerable performance improvements in automotive applications, as evidenced by examples such as the three-blade propeller.

The system's ability to deal with corrosion-resistant materials such as stainless steel and Inconel is critical for creating components that can tolerate harsh environments found in energy applications. The large-scale printing capabilities are especially useful for producing the huge parts that are commonly required in energy infrastructure. Furthermore, the system's repair and cladding capabilities have the potential to significantly extend the operating life of important energy sector equipment, thereby lowering downtime and replacement costs, both of which are critical in this business.

The system's capacity to operate with biocompatible materials, notably titanium, makes it ideal for the manufacturing of medical implants and equipment. Its capacity to construct complex geometries is especially useful for producing patient-specific implants or delicate medical devices. The technology's ability to create lightweight, efficient structures could transform the development of modern prosthetics and medical equipment.

Fill up the form below and we will send you the data sheet by e-mail.

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy