3D printers

High quality 3D printers

25% discount on your first order of 3D printed components!

SAVE DISCOUNT NOW!

The perfect symbiosis of quality and quantity!

Complex geometries with ideal properties!

High-resolution components with a wide variety of materials!

High-performance components with sustainable production!

A wide range of materials and ultra-fast production!

Ideal for a wide range of dental indications!

The process from simple component to product!

Fully automate your production!

Fast processing and successful management!

Sorry, there are no results for this combination of filters. Choose another combination of filters.

To ensure that all requests are handled promptly and completely, we ask that you submit all support requests through our support portal.

To the service portalDo you need assistance with your project, do you need advice or a sample part that we can send you?

Send Email

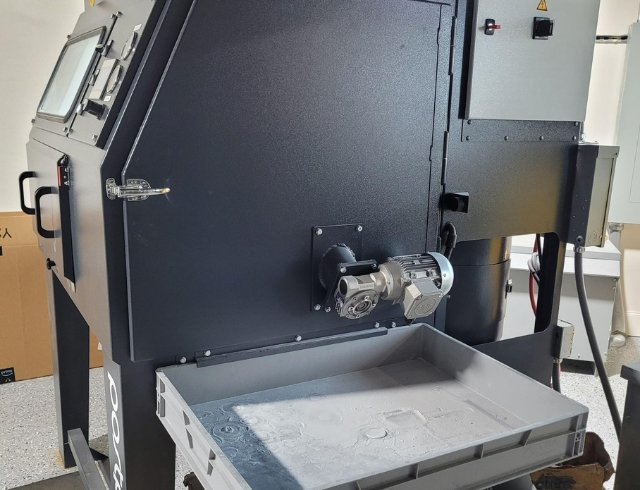

The PostPro SB is constructed as one compact unit, incorporating the blasting area and cyclone to minimize the machine footprint for efficient surface finishing capabilities.

The PostPro SB is an innovative automated surface blasting device that was precisely designed to improve the finishing quality of 3D printed parts. The PostPro SB uses mechanical methods such as shot blasting to effectively remove superfluous powder and greatly increase surface smoothness, which is critical for achieving both aesthetic appeal and functional performance in final products. The automation of the surface finishing process not only simplifies operations but also minimizes reliance on manual labor, which can cause irregularities and inconsistency in finishing results. By guaranteeing that each component is treated evenly, the PostPro SB enables manufacturers to produce consistent, high-quality finishes over several batches.

One of the PostPro SB's distinguishing qualities is its exceptional versatility in handling a wide range of part shapes and sizes. The system is specifically intended to accept both small and medium-sized components, making it appropriate for a wide range of applications across multiple industries. The PostPro SB's user-friendly interface improves operational efficiency by allowing operators to readily select parameters, monitor the finishing process in real time, and make modifications as needed depending on unique material needs or part designs. This simple control system not only decreases training time for new operators, but also eliminates the possibility of errors during operation, resulting in increased productivity and throughput.

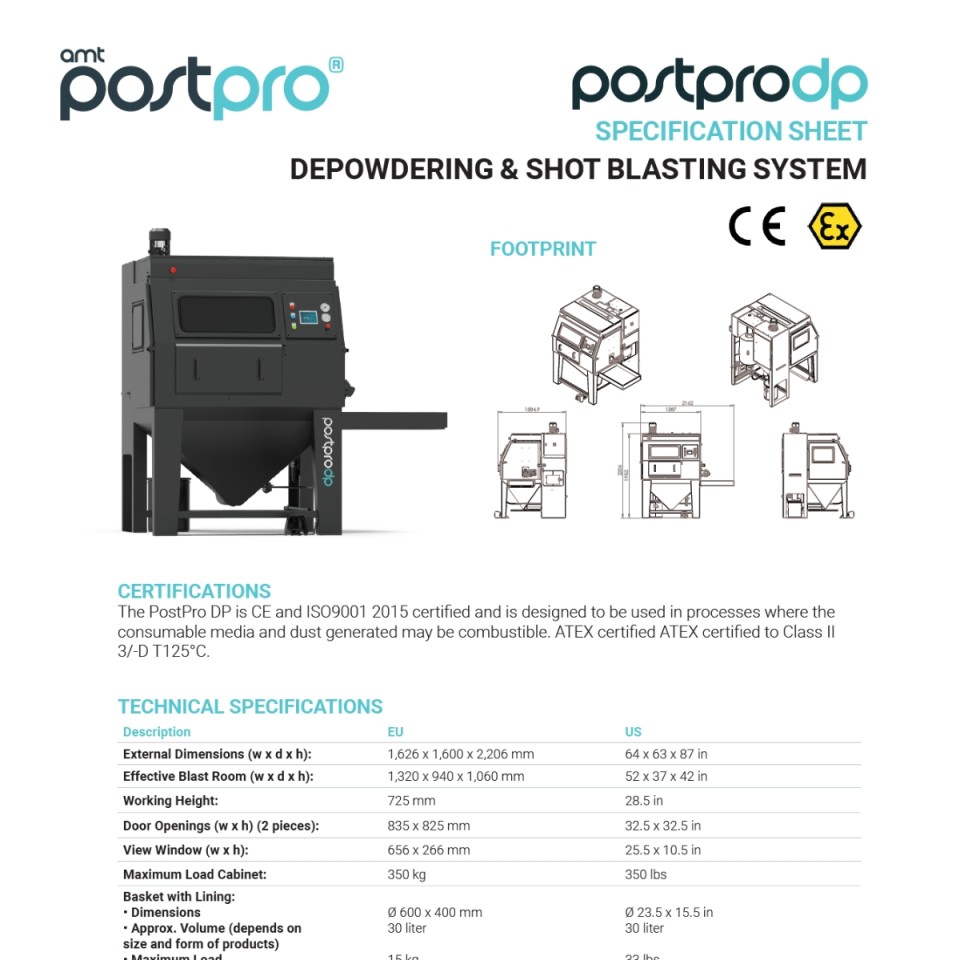

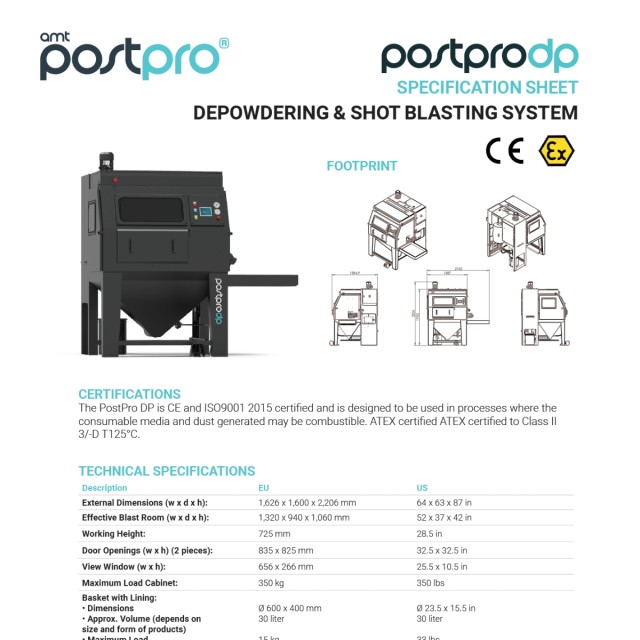

Technical specifications:

Basket Size: Ø600 x 400 mm

Basket Volume: 30 liters

Basket Loading Weight: 15 kg

Blast Gun: Double with Ø8 mm nozzle

The PostPro SB utitlizes automated surface blasting technology that uses compressed air and specialized media to efficiently remove surplus powder from 3D printed components. This automation considerably decreases the need for manual intervention, which can lead to inconsistent cleaning results. By following pre-set formulas and settings, the system guarantees that each part is treated uniformly, resulting in a high-quality finish that fulfills demanding industry requirements. This functionality is especially useful in high-volume production applications, where consistency across successive batches is critical for quality assurance.

One of the PostPro SB's distinguishing advantages is its ability to handle a wide variety of part geometries and sizes. The system is designed to accept small and medium-sized components, making it appropriate for a wide range of industries, including aerospace, automotive, and medical equipment. This versatility enables producers to process a wide range of items without requiring considerable reconfiguration or downtime in between tasks. The capacity to handle various types of parts efficiently improves operating efficiency and enables rapid response to changing production demands.

The PostPro SB has an intuitive user interface that makes operating easier and improves the entire user experience. The touchscreen control panel enables operators to simply browse through many settings and parameters, making it simple to configure and monitor the finishing process. This user-friendly design shortens the training period for new operators, allowing them to quickly become proficient in utilizing the system. Furthermore, real-time monitoring tools enable fast modifications as needed, assuring optimal performance

One key feature of the PostPro SB is its devotion to ecologically responsible operation. Unlike standard surface finishing systems, which frequently rely on toxic chemical solvents, the PostPro SB only uses mechanical processes. This environmentally responsible method not only decreases hazardous waste output, but also makes it easier to comply with health and safety laws. By eliminating the need for chemicals, businesses may embrace more environmentally friendly procedures while still producing high-quality finishes on their products.

The PostPro SB features an effective dust control technology that captures and contains particulate matter created during operation. This function keeps the working environment clean and safe for operators while increasing visibility during the finishing process. This dust management system contributes to a healthy workplace by minimizing dust accumulation within the chamber, as well as reducing the potential health concerns connected with airborne particles. The emphasis on cleanliness not only enhances operating efficiency but also corresponds with best practices for worker safety.

The PostPro SB was designed with operator ease in mind, including quick-clean maintenance features that allow for convenient waste disposal from the system. The enclosed dust bin allows workers to efficiently remove gathered dust and powder without causing a mess or exposing themselves to hazardous items. This practical design ensures a safer work environment by keeping contaminants contained during maintenance chores. These quick-clean technologies improve overall operational efficiency and help manufacturers comply with health and safety laws by streamlining waste management processes.

Fill up the form below and we will send you the data sheet by e-mail.

(This post processing machine has the same data sheet and specifications as the PostPro DP)

Cookie settings

We use cookies to provide you with the best possible experience. They also allow us to analyze user behavior in order to constantly improve the website for you. Privacy Policy