3D printers

High quality 3D printers

Leveraging cutting-edge blue laser technology and wire-laser deposition to fabricate metal components with unprecedented speed and efficiency, the Meltio M600 integrates a novel approach to energy delivery, optimising the metal printing process for enhanced productivity and material utilisation.

The Meltio M600 is an advanced industrial metal 3D printer that addresses issues such as long lead times, high inventory costs, and supply chain weaknesses. The M600 uses new blue laser technology and wire-laser deposition to boost printing speed, reduce energy consumption, and improve efficiency across a wide range of metal materials, including reflective ones such as copper and aluminium. The system has a huge build volume (300 x 400 x 600 mm), a totally inert chamber with oxygen levels as low as 10 ppm, and comprehensive process control to ensure constant part quality.

The M600's key features include dual and quad wire capabilities, which enable sequential printing with up to four distinct materials in a single job, as well as a hot wire capability that preheats the material to boost deposition rates. The machine is meant to integrate seamlessly into existing industrial facilities, requiring minimal operator interaction for 24/7 lights-out manufacturing. Its built-in 3-axis touch probe supports a wide range of workpiece types and allows for feature additions or repairs to existing parts. The M600 offers a cost-effective solution for industrial applications of metal additive manufacturing by reducing setup times and maintenance requirements, thanks to its user-friendly interface, the slicing software Meltio Horizon and the compact laser unit, in which all optical components are encapsulated.

Technical Specifications:

Print Envelope: 300 x 400 x 600 mm

Laser System: 9 Direct Diode Lasers, totaling 1000W

Laser Wavelength: 450 nm (Blue)

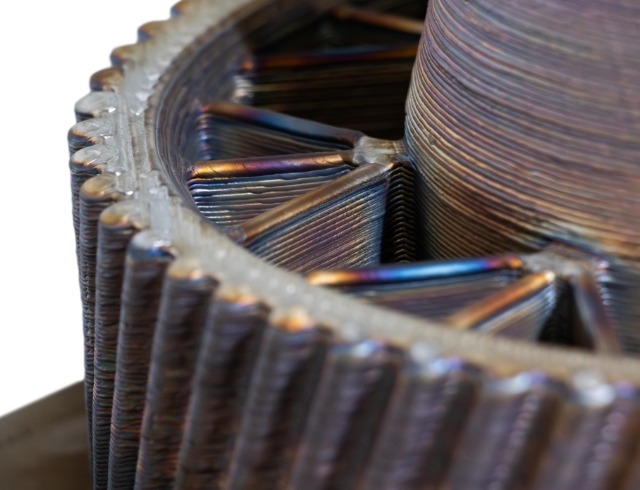

These blue lasers, with a wavelength of 450 nm, provide several significant benefits over typical near-infrared lasers as well as green lasers. First, they allow for faster printing, with the M600 printing 60% faster than its predecessor, the M450. This increased speed is accompanied by lower energy consumption due to the higher absorption rates of shorter wavelength light. Blue lasers are especially effective on reflective materials such as copper and aluminium, which are normally difficult for conventional laser systems. This enhanced absorption enables more effective processing of a diverse spectrum of metal materials, increasing the printer's versatility. The M600's blue laser deposition head, which integrates the lasers without the need of fibers, includes new and updated sensors for better print monitoring.

Meltio's Hot Wire technology on the M600 is a cutting-edge feature that improves the performance of their metal 3D printing machines. This configurable power source preheats the wire material before it reaches the melt pool, resulting in faster deposition rates and more energy efficiency. The Hot Wire technology enables for faster printing of big parts by lowering the energy required by lasers to fully melt the material, as well as optimising material flow potentially improving the mechanical qualities of the completed components. Its programmability allows customers to customise preheating parameters based on specific materials and part needs, increasing compatibility with a wide range of alloys.

The M600 can produce functionally graded components from up to four materials. Material composition can be gradually varied within the component to enhance specific requirements. Engineers can produce parts with precise The Dual Wire and Quad Wire options enable cost savings by using expensive materials only where absolutely necessary, while component geometries that are subject to lower mechanical, abrasive and thermal stress can This functionality expands the M600's range of applications and creates new possibilities in areas such as aerospace, automotive and medical, where parts made of multiple materials can offer significant

With an integrated piezoelectric touch sensor, the system can precisely position the laser head on the surface of the workpiece to be processed in order to apply material with pinpoint accuracy to different part geometries. This capability is particularly useful for making repairs to worn components or for reinforcing component geometries, as it allows the printer to determine exactly where material needs to be placed. The touch sensor detects the exact position and orientation of a workpiece and ensures that new features are applied in the correct place and orientation. In repair applications, it can map damaged areas so that the M600 can restore or reinforce specific parts of a part. This feature also supports a variety of workpiece mounting options, making it easy to integrate the M600 into existing manufacturing workflows.

The Meltio M600 has a sealed atmosphere control system that maintains an inert environment within the build chamber, resulting in excellent printing conditions. This method delivers ultra-low oxygen levels of only 10 parts per million (ppm), which is critical for preventing oxidation and protecting the integrity of sensitive metals during printing. Furthermore, the M600 has humidity control and a complete 3-stage particulate and chemical filtration system, which improves the regulated environment. These qualities make the M600 particularly appropriate for working with reactive materials such as titanium, aluminium, and copper alloys, eventually resulting in high-quality metal parts with exceptional mechanical properties and low oxidation.

The closed-loop process control of the Meltio M600 is an intelligent function that ensures consistent part quality through real-time monitoring and adaptive adjustments. Three high-speed cameras and pyrometers continuously monitor the weld seam and temperature of the molten pool, providing the system with important information. Similar to the M450, the M600 automatically adjusts the laser power and material feed rates based on this information to ensure optimal printing conditions. This adaptive control method detects and corrects anomalies during the printing process, reducing the likelihood of malfunctions. Closed-loop process control improves the overall reliability and quality of printed objects by constantly fine-tuning printing parameters, making the M600 a highly accurate and efficient metal 3D printing system.

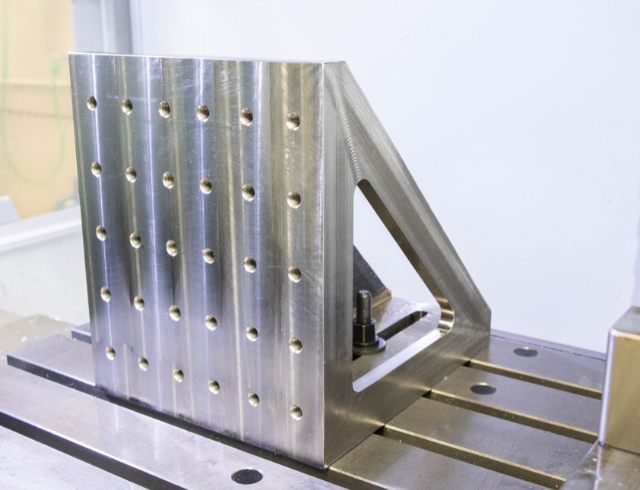

This system establishes a standardised interface between the machine table and workholding devices, enabling rapid and precise component positioning and clamping. The Zero Point Clamping System allows users to swiftly transition between workpieces or fixtures while retaining a positioning precision of less than 5 μm. This functionality is especially useful in hybrid manufacturing systems, as it allows for smooth transitions between the M600 and other manufacturing processes such as CNC machining or post-processing activities.

The Meltio M600 has exceptional material compatibility, making it an excellent choice for a variety of metal additive manufacturing applications. The system can handle a wide variety of metals, including stainless steel, mild steel, carbon steel, titanium alloys, nickel alloys and even copper and aluminium. This diversity enables users to choose the best material for their unique project needs, such as corrosion resistance, high strength, or heat tolerance. The M600's ability to work with titanium alloys is also important, since it offers up new opportunities in the aerospace and medical industries, where lightweight, strong materials are critical.

The Meltio M600 is designed to seamlessly integrate into existing manufacturing environments, making it an excellent addition to modern machine shops and production facilities. Its design philosophy promotes interoperability with CNC machine operations, allowing it to operate alongside traditional subtractive manufacturing techniques. The M600's high level of autonomy lowers the need for operator involvement, allowing for 24/7 lights-out production processes. The machine's factory-aligned deposition head enhances its autonomous capacity by eliminating the need for human laser alignment and dramatically reducing maintenance requirements. The system's user-friendly interface and quick programming using Meltio Horizon software make setup and operation simple, even for individuals new to additive manufacturing.

The M600 is ideal for manufacturing complicated, lightweight components for the aerospace and defense industries. Its ability to work with titanium alloys and Inconel makes it excellent for producing high-strength, heat-resistant parts including engine components, structural elements, and custom brackets. The machine's precision and capacity to create fully dense pieces exceed the demanding quality standards of these industries.

For automotive applications, the M600 provides rapid prototyping and small-scale manufacture of specialised parts. Its fast deposition rate and flexibility to work with a wide range of metals make it ideal for manufacturing engine components, exhaust systems, and structural elements. The machine's dual feedstock capacity enables the production of functionally graded materials, which can be especially beneficial in high-performance automotive applications.

The M600's capabilities are extremely beneficial to the oil and gas industry. The machine's ability to deal with corrosion-resistant alloys such as Inconel and stainless steel is critical for manufacturing components that can tolerate hostile environments. The huge build volume enables the fabrication of big parts, while the ability to repair and add features to existing components can be extremely useful for maintaining and updating equipment in remote areas, lowering downtime and logistical costs.

The M600 is designed to work smoothly with existing machine shop setups. Its interoperability with CNC processes, low operator engagement needs, and ability to operate continuously make it an excellent complement to ordinary machine shops. The ability to make entire parts, add features to existing components, and execute repairs all within a single system provides machine shops with new capabilities and revenue opportunities.